Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

As environmental regulations become increasingly strict and sustainable production becomes a global priority, titanium anode for organic wastewater treatment has emerged as a key technology in modern wastewater management. This advanced electrochemical solution offers high efficiency, durability, and eco-friendly performance in removing complex organic pollutants from industrial effluents.

What Is a Titanium Anode for Organic Wastewater Treatment?

A titanium anode for organic wastewater treatment is a high-performance electrochemical electrode used to degrade and mineralize organic contaminants present in wastewater. It works through electrochemical oxidation, where electrical energy transforms harmful organic compounds into harmless substances such as carbon dioxide and water.

Technical Parameters of Titanium Anode for Organic Wastewater Treatment

|

Parameter |

Typical Value |

|

Substrate material |

Titanium (Gr1 / Gr2) |

|

Coating type |

IrO₂, RuO₂, PbO₂, or MMO |

|

Current density |

100–1000 A/m² |

|

Cell voltage |

3.5–6.0 V |

|

Operating temperature |

20–60°C |

|

Lifespan |

3–10 years (depending on application) |

|

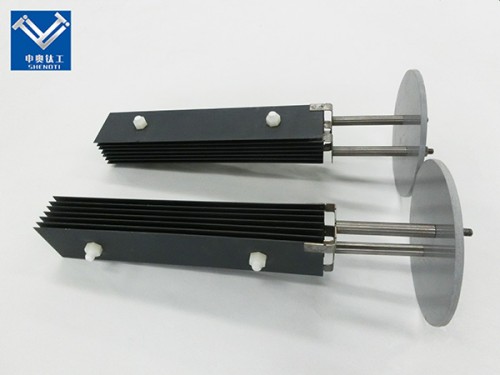

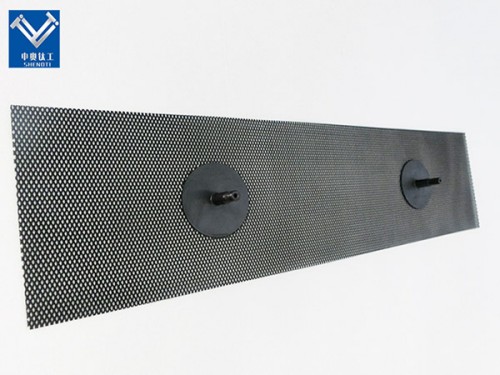

Form |

Plate, mesh, or tube |

|

Oxidation efficiency |

>90% for most organic compounds |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Titanium Anode for Organic Wastewater Treatment

The titanium anode for organic wastewater treatment offers several distinct advantages over traditional graphite or lead-based electrodes.

1. Excellent Corrosion Resistance

Titanium’s natural oxide layer provides outstanding resistance against acidic or alkaline wastewater, extending the electrode’s service life to over 5–10 years depending on usage.

2. High Oxidation Efficiency

MMO or PbO₂ coatings enable efficient generation of hydroxyl radicals, ensuring rapid degradation of complex organic pollutants.

3. Environmentally Friendly

The electrochemical oxidation process produces no harmful sludge or chemical by-products, aligning with green chemistry principles.

4. Low Energy Consumption

Optimized electrode design reduces cell voltage and energy costs while maintaining high oxidation efficiency.

5. Easy Maintenance and Reusability

The anodes require minimal maintenance and can be recoated or refurbished, lowering operational costs.

Applications of Titanium Anode for Organic Wastewater Treatment

Due to its versatility and reliability, titanium anode for organic wastewater treatment is widely applied in multiple industrial sectors where organic contamination is prevalent.

1. Chemical and Pharmaceutical Industry

Used to treat wastewater containing phenols, chlorinated hydrocarbons, antibiotics, and dyes, titanium anodes effectively oxidize refractory organics that biological treatment cannot handle.

2. Petrochemical and Refining Industry

In petroleum refining, effluents often contain hydrocarbons, surfactants, and lubricants. Titanium anodes break these down efficiently, reducing chemical oxygen demand (COD) to meet discharge standards.

3. Textile and Dyeing Industry

Dye wastewater is notorious for its color and toxicity. Electrochemical oxidation using titanium anodes achieves high decolorization rates and total organic carbon (TOC) removal.

4. Electroplating and Printed Circuit Board (PCB) Industry

The technology helps in the oxidative degradation of organic additives and cleaning of process wastewater, ensuring compliance with environmental regulations.

5. Food and Beverage Industry

Used to treat high-COD wastewater from food processing, slaughterhouses, and beverage production, titanium anodes provide a clean and effective treatment route.

Real-World Applications Case:

1: Pharmaceutical Factory Wastewater Treatment

A pharmaceutical manufacturer in East Asia adopted titanium anode for organic wastewater treatment to handle antibiotic-laden effluents. After installation, COD removal efficiency exceeded 90%, and operating costs dropped by 30% compared to conventional oxidation methods.

2: Textile Dyeing Plant

In a textile plant wastewater system, titanium anodes achieved 95% color removal and significant reduction in chemical oxygen demand (COD) without producing sludge, greatly simplifying downstream treatment.

3: Petrochemical Wastewater

A petrochemical enterprise integrated electrochemical oxidation with biological treatment. Titanium anodes served as the front-end oxidation step, successfully converting refractory organics into biodegradable intermediates, enhancing overall system efficiency.

|

|

|

|

|

|

|

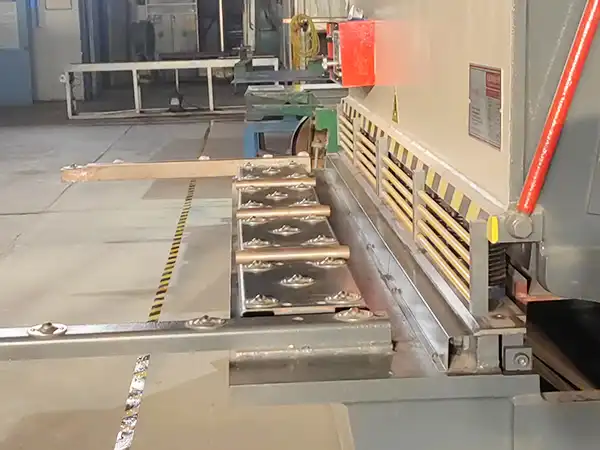

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Titanium Anodes from Baoji City ShenAo Metal Materials Co., Ltd.?

As a leading manufacturer specializing in titanium anode for organic wastewater treatment, Baoji City ShenAo Metal Materials Co., Ltd. offers customized electrode solutions designed for reliability and performance.

Our Core Strengths

Over 15 years of expertise in titanium and non-ferrous metal materials

In-house coating formulation and precision welding technology

Comprehensive testing and quality control system

Customized designs for voltage, shape, and coating type

Global service and technical support

Each titanium anode is engineered to deliver superior electrochemical efficiency, ensuring stable operation even under challenging wastewater conditions.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is the typical lifespan of a titanium anode?

The lifespan ranges from 5 to 20 years, depending on the operating environment and maintenance practices.

Q2: Can the anodes be customized to fit specific reactors?

Yes, we provide customized shapes and sizes, including mesh, tubular, and plate designs.

Q3: Are these anodes environmentally friendly?

Absolutely. Our anodes minimize the need for chemical additives, reducing environmental impact.

Contact Us

Let us help you optimize your wastewater treatment processes.

- Company: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City, China

- Contact: Wang Shujuan

- Phone: +86 18729731603

- Email: zh@baojiti.com.cn

Enhance your wastewater treatment systems with the reliability and performance of Titanium anode for organic wastewater treatment. Contact us today to learn more or request a quote!

YOU MAY LIKE

_1735356385558.webp)