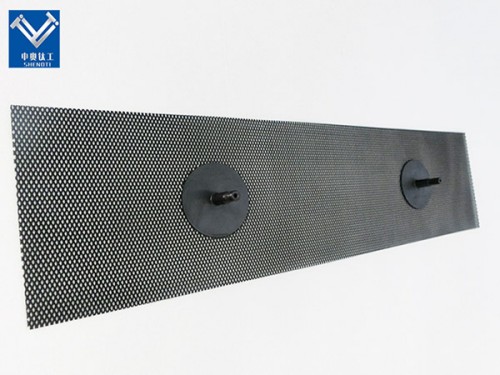

Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

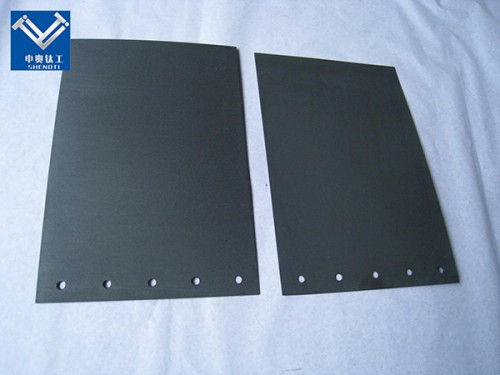

Customizable sizes for various industrial applications.

Titanium anode for circulating water descaling are revolutionizing water treatment systems with their superior corrosion resistance, durability, and efficiency. Designed for industries where scaling and corrosion are major concerns, these anodes ensure a cleaner, more sustainable water circulation process. Baoji City ShenAo Metal Materials Co., Ltd., nestled in the prestigious "China Titanium Valley," is a leading manufacturer of titanium anodes that leverages sophisticated double-metal explosive welding and active coating technologies. These advanced methods ensure the anodes' exceptional performance and longevity.

The company's titanium anodes are designed to be highly effective in a variety of applications, particularly in chemical processing where they contribute to efficient reactions and product quality enhancement. In environmental protection, these anodes play a crucial role in water treatment systems by facilitating electrolysis to eliminate impurities, thereby protecting aquatic ecosystems and ensuring clean water supply.

Technical Parameters of Titanium Anodes for Descaling

|

Parameter |

Typical Value |

|

Substrate Material |

Gr1 / Gr2 Titanium |

|

Coating Composition |

RuO₂ + IrO₂ + TiO₂ |

|

Working Current Density |

50–300 A/m² |

|

Coating Thickness |

3–10 µm |

|

Operating Temperature |

≤ 80°C |

|

pH Range |

2–12 |

|

Expected Service Life |

5–10 years |

These parameters can be adjusted according to system water quality, flow rate, and installation design.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Titanium Anode for Circulating Water Descaling

1. Chemical-Free Descaling

Unlike traditional descaling methods that rely on acid cleaning or chemical inhibitors, titanium anodes use electrochemical reactions to generate oxidants, achieving zero-chemical operation and eco-friendly water treatment.

2. Long Service Life

The noble metal oxide coating offers excellent resistance to corrosion and wear. Depending on water quality and current density, a titanium anode can operate for 5 to 10 years with minimal maintenance.

3. Stable and Efficient Performance

The titanium anode for circulating water descaling provides consistent current distribution, ensuring continuous descaling and disinfection even in harsh conditions.

4. Reduced Operating Costs

By preventing scale buildup and reducing heat exchanger fouling, the system’s energy efficiency improves while maintenance downtime and chemical consumption are minimized.

5. Safety and Automation

The system operates at low voltage, with simple automatic control, making it safer and easier to integrate into existing industrial water systems.

Applications of Titanium Anodes in Circulating Water Systems

1. Power Plants

Power stations use vast circulating water systems for cooling turbines and condensers. Titanium anodes prevent scaling and corrosion, maintaining high thermal efficiency and extending equipment life.

2. Petrochemical and Chemical Industries

In refineries and chemical plants, cooling water often contains high levels of minerals and organic compounds. Titanium anodes for circulating water descaling effectively suppress scale and microbial growth without contaminating the process.

3. Metallurgy and Steel Plants

Cooling towers in steel production face serious scale accumulation due to high water hardness. Titanium anodes maintain clean pipelines and improve water circulation efficiency.

4. HVAC and Central Air Conditioning

Commercial buildings and industrial complexes use circulating water descaling titanium anodes in their HVAC systems to prevent pipe scaling, improve energy efficiency, and reduce maintenance.

5. Marine and Desalination Systems

Titanium’s natural resistance to seawater corrosion makes it ideal for marine cooling circuits and reverse osmosis desalination plants.

Real-World Case :Titanium Anodes in Circulating Water Systems

1: Power Plant Cooling Tower

A 300MW power station in Southeast Asia replaced traditional chemical dosing with titanium anodes. After 6 months, scale thickness decreased by 70%, water conductivity stabilized, and heat exchanger efficiency improved by 12%.

2: Petrochemical Cooling System

A refinery in the Middle East installed titanium anodes for circulating water descaling across its cooling network. The system achieved continuous operation for over 4 years without significant scale formation or corrosion.

3: Central HVAC System

A commercial complex equipped with titanium anodes reduced maintenance intervals from once every 3 months to once per year, saving approximately 30% of operational costs.

|

|

|

|

|

|

|

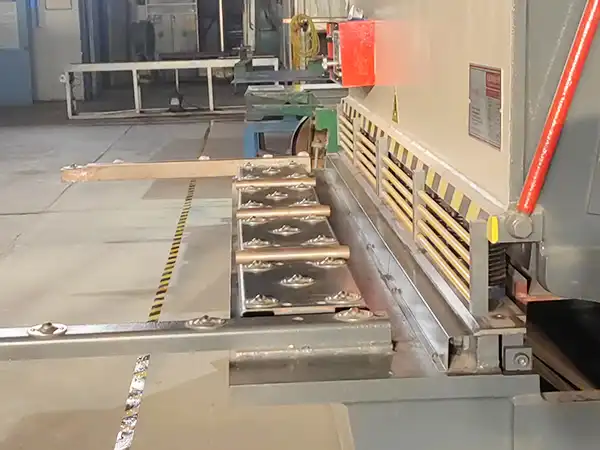

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

1. Research and Innovation

Our dedicated R&D team continuously explores new materials and applications, ensuring that our products meet and exceed industry standards.

2. Excellent Reputation

With 17 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. has earned the trust of clients worldwide for our commitment to quality and customer satisfaction.

3. Striving for Excellence

We adhere to rigorous production processes and a robust quality management system, delivering reliable and stable products every time.

4. Customized Solutions

We provide tailored products to meet the unique technical requirements of each customer, ensuring optimal performance for their specific applications.

5. Timely Delivery and Support

Our customer-centric approach ensures fast delivery and comprehensive after-sales service, making your experience hassle-free.

OEM Services

We offer OEM services for all our products, including customized sizes, coatings, and designs. Whether you need a small batch for testing or a large-scale production run, we’ve got you covered.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: How do titanium anodes reduce scaling in water systems?

Titanium anodes emit a low voltage that prevents mineral buildup on surfaces, significantly reducing scale formation.

Q2: What industries benefit most from these anodes?

Industries like power generation, chemical processing, and environmental protection see the greatest benefits.

Q3: Can I get a custom design for my specific application?

Yes, we specialize in customized solutions tailored to your exact needs.

Contact Us

Let us help you achieve efficient water descaling with our premium titanium anodes.

- Name: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Our Titanium anode for circulating water descaling are engineered to meet the highest standards of performance and sustainability. Explore our innovative solutions today and experience unparalleled efficiency in your water treatment systems!

YOU MAY LIKE

_1735356385558.webp)