Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

Titanium Anode for Electrolytic Water Treatment Introduction

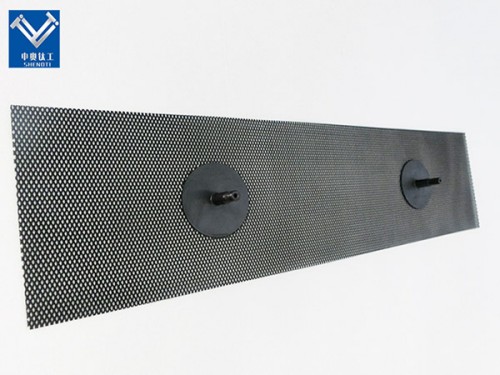

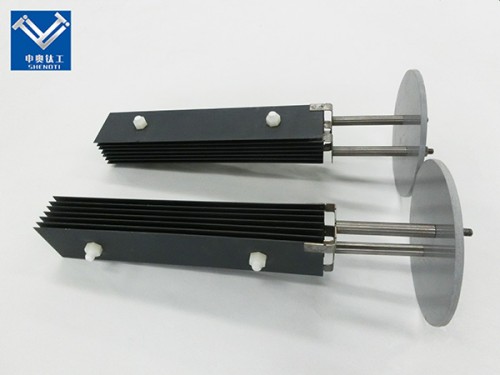

The Titanium Anode for Electrolytic Water Treatment is a cutting-edge solution designed to enhance the efficiency and longevity of water treatment systems. Engineered with premium titanium substrates and advanced coatings, our titanium anodes deliver superior corrosion resistance, exceptional conductivity, and minimal environmental impact. Perfect for industries such as chemical processing, environmental protection, and energy, these anodes are essential for high-performance electrolytic applications.

Baoji City ShenAo Metal Materials Co., Ltd. specializes in producing high-quality Titanium anode for electrolytic water treatment, designed to meet the demanding needs of various sectors. The technology behind these plates ensures that the steel core provides structural integrity, while the stainless steel exterior offers enhanced durability, resistance to corrosion, and a longer service life. These plates are manufactured with precision and quality standards, making them ideal for use in severe operating environments.

Technical Specifications

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Using Titanium Anode for Electrolytic Water Treatment

1. High Durability and Low Maintenance

Titanium’s inherent corrosion resistance reduces replacement frequency, saving operational costs.

2. Energy Efficiency

The optimized coating structure lowers cell voltage, ensuring energy-efficient electrolysis with minimal power consumption.

3. Environmentally Friendly Operation

No additional chemicals are required, and the system produces no secondary pollution — a perfect fit for green industry standards.

4. Superior Oxidation Ability

The generated hydroxyl radicals and active chlorine achieve deep oxidation, effectively decomposing complex organic compounds.

5. Flexible Customization

Manufacturers like Baoji ShenAo Metal Materials Co., Ltd. offer customizable titanium anodes in various shapes — mesh, plate, rod, or tubular — to suit different electrolytic cell configurations.

Applications of Titanium Anode in Electrolytic Water Treatment

1. Industrial Wastewater Treatment

Titanium anodes are used to remove COD, BOD, ammonia nitrogen, and phenolic compounds from industrial wastewater generated by electroplating, chemical, pharmaceutical, and textile industries.

2. Municipal Water Disinfection

Electrolytic generation of chlorine or ozone via titanium anodes provides an effective and chemical-free method for sterilizing tap water, swimming pools, and sewage systems.

3. Electrolyzed Oxidation in Food Processing

In the food and beverage industry, titanium anodes ensure hygienic production environments by generating strong oxidizing agents that kill microorganisms and degrade organic residues.

4. Marine and Desalination Systems

For seawater treatment and desalination plants, titanium anodes withstand chloride corrosion and maintain long-term operational stability in saline environments.

5. Groundwater and Domestic Water Purification

Compact electrolytic systems equipped with titanium anodes are increasingly used in residential and small-scale purification systems for safe drinking water.

Titanium Anode for Electrolytic Water Treatment Case :

1: Electrolytic Treatment of Printing Wastewater

A printing factory in Southeast Asia adopted a titanium anode-based electrolysis system to treat wastewater containing dyes and surfactants. Results showed a 70% reduction in COD and a significant improvement in effluent clarity, with system maintenance reduced by 50%.

2: Chlorine Generation for Swimming Pools

In a municipal pool project, MMO-coated titanium anodes replaced traditional chlorine dosing systems. The electrolytic process provided consistent chlorine levels, reduced chemical storage risks, and lowered operating costs.

3: Desalination Plant Application

For a coastal desalination facility, DSA titanium anodes were used for anti-biofouling systems. Their stability and low energy consumption extended service life beyond five years under continuous operation.

|

|

|

|

|

|

|

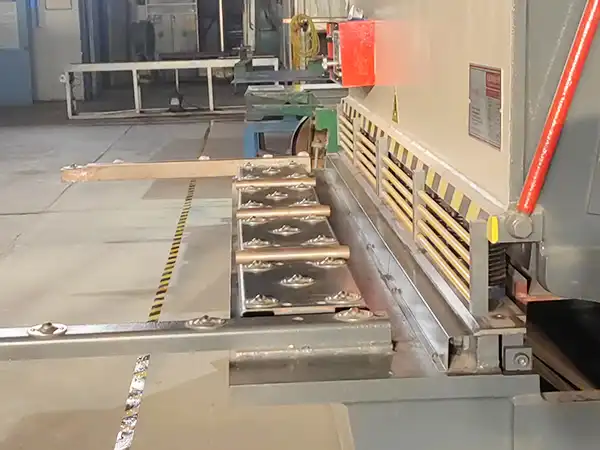

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Baoji City ShenAo Metal Materials Co., Ltd.?

Located in China’s “Titanium Valley” — Baoji — ShenAo Metal Materials Co., Ltd. specializes in the design, manufacturing, and export of titanium anodes for electrolytic water treatment and other non-ferrous metal products. With advanced explosion bonding, coating, and machining technologies, ShenAo provides custom solutions for global clients across chemical, environmental, and energy industries.

Our Strengths

Over 20 years of expertise in titanium electrode manufacturing

Strict quality control and ISO-certified production process

Customizable anode coatings and structures

Global delivery and technical support

OEM Services

We deliver a comprehensive range of OEM services designed for clients seeking bespoke products or distinctive design implementations. Through our partnership, you'll experience a streamlined and personalized manufacturing process that transforms your brand's concept into a reality with meticulous attention to detail and professional acumen. Our dedication to customizing solutions and maintaining high-quality standards guarantees that the final products not only align with your specifications but also surpass the expectations of your clientele about Titanium Anodes for Electrolytic Water Treatment.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: What industries benefit most from Titanium anode for electrolytic water treatment?

A: Industries such as wastewater treatment, seawater desalination, electroplating, and hydrogen production find our titanium anodes invaluable.

Q2: How do I determine the best coating for my application?

A: Our team provides expert advice based on your operating conditions, such as pH range and current density requirements.

Q3: Can you customize the size and shape of the anodes?

A: Yes, we design titanium anodes to fit your specific system requirements.

Q4: How long do titanium anodes last?

A: Service life typically exceeds three years, depending on usage and maintenance.

Contact Us

Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

Partner with us for reliable and high-performance Titanium Anodes for Electrolytic Water Treatment. Together, we’ll transform your water treatment processes with efficiency, sustainability, and innovation.

YOU MAY LIKE