Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

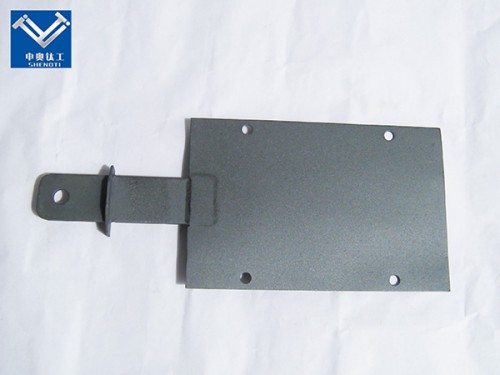

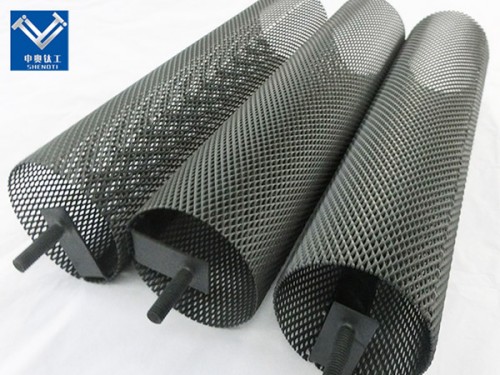

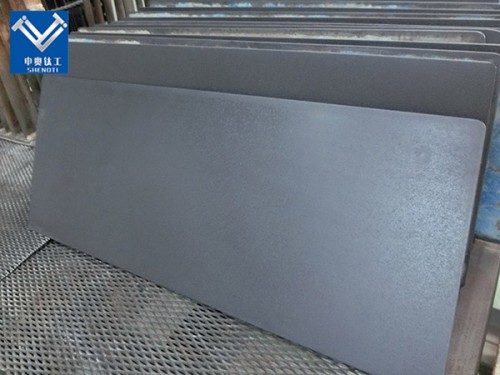

Customizable sizes for various industrial applications.

In the modern textile and dyeing industry, printing and dyeing wastewater treatment has become a major challenge due to the complexity and persistence of organic dyes and chemicals. Among the various treatment technologies available, the titanium anode for printing and dyeing wastewater treatment has emerged as one of the most efficient and environmentally friendly solutions. This innovative electrode material offers high corrosion resistance, long service life, and strong oxidizing capability, making it ideal for industrial-scale wastewater purification systems.

A titanium anode is an electrochemical component made from high-purity titanium substrate, coated with precious metal oxides such as ruthenium oxide (RuO₂), iridium oxide (IrO₂), or mixed metal oxide (MMO). When used in printing and dyeing wastewater treatment, the titanium anode serves as the positive electrode in an electrolysis system, generating powerful oxidants like hydroxyl radicals (•OH) and active chlorine species to degrade organic pollutants effectively.

Technical Specifications

|

Parameter |

Specification |

|

Substrate Material |

Titanium (Gr1/Gr2) |

|

Coating Type |

IrO₂–Ta₂O₅ / RuO₂–TiO₂ MMO |

|

Operating Current Density |

10–100 A/m² |

|

Operating Temperature |

≤60°C |

|

pH Range |

1–14 |

|

Service Life |

5–10 years |

|

Application |

Textile wastewater, electrolysis oxidation systems, COD reduction |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Titanium Anode for Printing and Dyeing Wastewater Treatment

1. High Efficiency in Dye Degradation

The titanium anode enables complete mineralization of organic dyes, removing color and reducing COD (Chemical Oxygen Demand) efficiently without the need for chemical reagents.

2. Long Service Life and Stability

Thanks to the strong adhesion of the MMO coating and the corrosion-resistant titanium substrate, the anode can operate continuously for over 5–10 years, depending on the application conditions.

3. Energy Saving and Low Maintenance

With low overpotential and high current efficiency, titanium anodes consume less energy and require minimal maintenance, making them cost-effective for long-term operation.

4. Environmental Sustainability

Unlike traditional chemical treatment methods, this process produces no secondary pollution or harmful sludge, promoting sustainable and green wastewater treatment.

Applications of Titanium Anode in Printing and Dyeing Wastewater Treatment

1. Textile and Dyeing Plants

The most common application is in textile dyeing effluent treatment, where titanium anodes decolorize wastewater containing azo dyes, reactive dyes, and sulfur dyes.

2. Electrochemical Advanced Oxidation (EAOP) Systems

Titanium anodes are key components in EAOP systems, which combine electrolysis and oxidation to degrade persistent organic pollutants efficiently.

3. Decolorization and COD Reduction Units

They are used for color removal and COD reduction, meeting strict environmental discharge standards set by national and international agencies.

4. Zero Liquid Discharge (ZLD) Processes

Titanium anodes support ZLD technologies, allowing factories to recycle and reuse treated water, thus reducing overall water consumption and improving sustainability.

Successful Application in a Dyeing Factory Case:

A textile factory in Southeast Asia adopted a titanium anode wastewater treatment system to replace its conventional Fenton oxidation process.

System Parameters: Current density of 50 A/m², operating temperature 30°C

Results:

Color removal rate: >95%

COD reduction: >85%

Operating cost reduced by 30%

Maintenance cycle extended to 18 months

This case demonstrates the reliability and cost-effectiveness of titanium anode technology for large-scale printing and dyeing wastewater treatment.

|

|

|

|

|

|

|

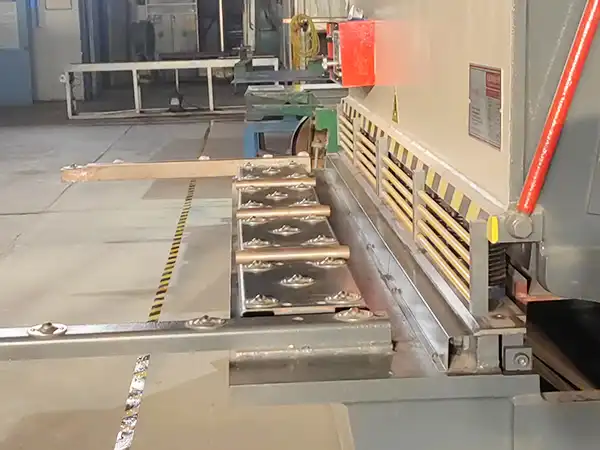

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Our Titanium Anodes

Baoji City ShenAo Metal Materials Co., Ltd. is a leading manufacturer specializing in titanium anodes and MMO coated electrodes. With advanced production technology, precision coating equipment, and strict quality control, we provide custom solutions tailored to your wastewater characteristics and treatment goals.

Our Strengths

15+ years of experience in titanium and MMO electrode production

ISO 9001 certified factory with complete testing equipment

Customized anode size, shape, and coating formula

Professional technical support and after-sales service

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

OEM Services

Leverage our expertise to develop private-label products tailored to your brand’s unique specifications.

Frequently Asked Questions (FAQs)

1. What is the typical lifespan of your titanium anodes?

Our titanium anodes typically last over 5 years, depending on operational conditions and maintenance.

2. Can I customize the coating material?

Yes, we offer customizable coatings, including Mixed Metal Oxides (MMO) and Platinum, based on your specific application needs.

3. How does your product support sustainability?

Our titanium anodes reduce the need for chemicals in wastewater treatment, lowering environmental impact while enhancing operational efficiency.

Contact Us

Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Discover how our Titanium Anode for Printing and Dyeing Wastewater Treatment can revolutionize your wastewater management processes. Contact us today for a tailored solution that meets your needs.

YOU MAY LIKE

_1735356385558.webp)