Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

What Is an MMO Coated Titanium Electrode?

The MMO coated titanium electrode (Mixed Metal Oxide coated titanium electrode) is a highly advanced electrochemical material widely applied in industrial processes. Designed for durability, efficiency, and corrosion resistance, it combines a titanium substrate with a specialized mixed metal oxide coating. This innovative design ensures excellent conductivity, long service life, and stable electrochemical performance in harsh environments.

An MMO coated titanium electrode is composed of two critical layers:

Titanium substrate – Provides excellent mechanical strength, corrosion resistance, and a lightweight structure.

Mixed metal oxide (MMO) coating – Typically consists of ruthenium oxide (RuO₂), iridium oxide (IrO₂), or a combination of noble metal oxides. This coating significantly improves the electrode’s electro-catalytic activity and conductivity.

Manufacturing Process of MMO Coated Titanium Electrode

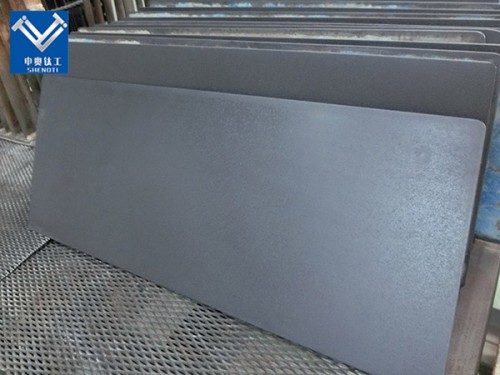

1: Titanium Substrate Preparation

High-purity titanium plates, tubes, or meshes are selected as the base material. The surface undergoes mechanical polishing, sandblasting, and chemical cleaning to remove oxides and impurities. This preparation guarantees strong adhesion between the titanium and the MMO coating.

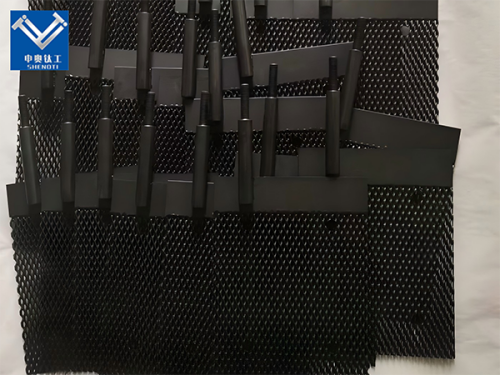

2: MMO Coating Application

Using techniques such as thermal decomposition or brush-coating, a solution containing metal salts of ruthenium, iridium, and other oxides is applied. The electrode is repeatedly coated and baked at high temperatures to achieve uniform thickness and strong bonding.

3: Quality Testing

Electrodes are tested for adhesion strength, coating uniformity, and electrochemical performance. Laboratory tests such as accelerated life testing and current density analysis ensure the MMO coated titanium electrode meets international standards.

4: Customization

Depending on customer requirements, the coating composition, thickness, and electrode shape can be customized for specific applications, such as anode or cathode use in different electrochemical systems.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of MMO Coated Titanium Electrode

High electrical conductivity

Superior corrosion resistance

Excellent electro-catalytic activity

Long service life (up to 20 years depending on operating conditions)

Customizable coating compositions to match industrial needs

Industrial Applications of MMO Coated Titanium Electrode

1: Water Treatment and Wastewater Management

Used in electrochlorination systems to generate sodium hypochlorite for water disinfection.

Plays a vital role in advanced oxidation processes (AOPs) for breaking down organic pollutants.

Ensures stable operation under high current densities, providing cost-effective wastewater treatment solutions.

2: Cathodic Protection

Protects pipelines, offshore platforms, and storage tanks from corrosion.

The MMO coating ensures consistent current output and long-term durability.

Reduces maintenance costs by extending the service life of critical infrastructure.

3: Electroplating and Surface Treatment

Applied in chrome plating, copper plating, and precious metal recovery.

Provides stable current efficiency and uniform plating results.

Reduces the use of harmful lead-based electrodes, supporting green manufacturing.

4: Chlor-Alkali Industry

Widely used in the production of chlorine and caustic soda.

Delivers high efficiency and low energy consumption during electrolysis.

Withstands highly corrosive environments without degradation.

5: Energy Storage and Emerging Technologies

Integrated into hydrogen production systems and fuel cells.

Applied in electrochemical energy storage devices, including flow batteries.

Supports renewable energy integration through high-efficiency electrolysis.

MMO Coated Titanium Electrode Applications Case

1: Municipal Water Disinfection

A European water utility replaced traditional graphite electrodes with MMO coated titanium electrodes in their electrochlorination system. The result was a 40% reduction in energy consumption and improved chlorine production stability.

2: Offshore Oil & Gas Cathodic Protection

In the Middle East, MMO coated titanium anodes were installed to protect offshore oil rigs. With a projected service life of over 25 years, the system drastically reduced annual maintenance costs compared to conventional cathodic protection methods.

3: Electroplating Industry in Asia

An electroplating factory switched to MMO coated titanium electrodes for chrome plating. This eliminated the environmental hazards of lead-based electrodes, increased plating quality, and enhanced workplace safety.

Advantages of MMO Coated Titanium Electrode

Extended service life under aggressive conditions

High energy efficiency reducing operational costs

Eco-friendly alternative to traditional lead-based electrodes

Customizable design for specific industries

Stable performance with minimal maintenance requirements

|

|

|

|

|

|

|

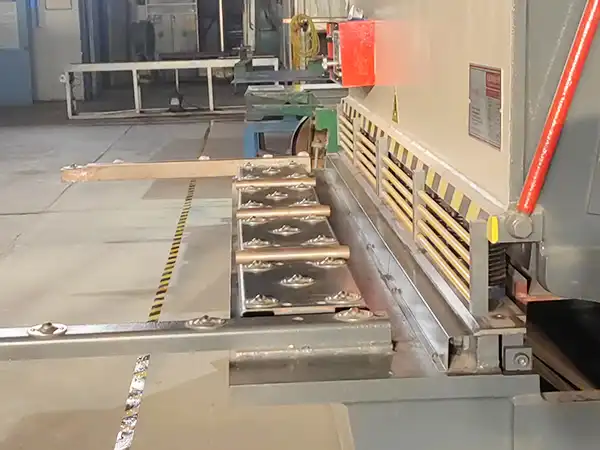

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Frequently Asked Questions (FAQs)

1: How long does an MMO coated titanium electrode last?

Depending on usage and coating type, MMO coated titanium electrodes can last between 2 and 10 years, making them an excellent long-term investment.

2: Can MMO electrodes be reused?

The titanium substrate can often be recoated once the MMO layer wears out, extending the total lifecycle of the electrode and reducing replacement costs.

3: Are MMO coated titanium electrodes suitable for seawater applications?

Yes, particularly ruthenium-based coatings are highly effective in seawater electrolysis, commonly used in chlorine generation and marine cathodic protection systems.

4: What is the typical lead time for custom MMO electrodes?

Lead times vary by complexity and order quantity but generally range from 2–4 weeks for custom designs.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: What is an product?

A: An product is a titanium electrode that is coated with a mixed metal oxide layer, providing excellent corrosion resistance and conductivity, suitable for electrochemical applications.

Q2: What industries use the products?

A: These electrodes are used in industries such as water treatment, chemical processing, electroplating, energy generation, and seawater desalination.

Q3: What is the service life of an product?

A: The service life typically ranges from 5 to 10 years, depending on the application and operating conditions.

Q4: Can products be customized?

A: Indeed, we offer customizable sizes, coatings, and designs to meet specific customer needs.

Q5: Are MMO Coated Titanium Electrodes environmentally friendly?

A: Yes, these electrodes are designed to contribute to sustainable and energy-efficient processes, especially in water treatment and energy generation.

Contact Details

Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

E-mail: zh@baojiti.com.cn

For more details or to place an order, feel free to contact us! We're here to assist you with all your metal material needs.

YOU MAY LIKE

_1735356385558.webp)