The reason titanium is used as the substrate lies in its unique combination of mechanical strength, lightweight structure, and strong resistance to corrosion. When coated with a mixed metal oxide (MMO) or platinum layer, it transforms into a highly stable dimensionally stable anode (DSA)—the heart of efficient seawater electrolysis technology.

A titanium anode for electrolysis of seawater is an electrochemical component designed to convert seawater into chlorine gas (Cl₂) and other useful compounds through electrolysis. In this process, seawater acts as the electrolyte, while the titanium anode serves as the positive electrode. When electric current passes through the system, chloride ions (Cl⁻) are oxidized at the anode, producing chlorine gas that can be used for sterilization, water purification, or chemical synthesis.

Technical Specifications

| Parameter | Specification |

|---|---|

| Base Material | Titanium (Grade 1/Grade 2) |

| Coating Material | Mixed metal oxides (MMO) or platinum |

| Operating Temperature | 0°C to 80°C |

| Maximum Current Density | 2000 A/m² |

| Coating Thickness | 5-10 microns |

| Service Life | 5-20 years (application-dependent) |

| Dimensions | Customizable based on requirements |

| Electrolyte Compatibility | Seawater, brine, and chlor-alkali solutions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical Advantages of Titanium Anode for Seawater Electrolysis

1. Exceptional Corrosion Resistance

Titanium itself forms a natural oxide layer that protects it from the corrosive effects of chloride ions. When combined with MMO or platinum coatings, the anode becomes virtually immune to seawater corrosion, extending its lifespan up to 10–15 years in continuous operation.

2. High Electrochemical Efficiency

The catalytic coatings on titanium significantly lower the chlorine evolution potential, reducing energy consumption during electrolysis. This translates to higher production efficiency and lower operating costs.

3. Long Service Life

Unlike graphite or conventional metal anodes, titanium anodes for electrolysis of seawater maintain dimensional stability over long periods, preventing electrode deformation or degradation.

4. Environmentally Friendly

The anode operates cleanly without producing harmful by-products, aligning perfectly with modern environmental standards for marine and water treatment industries.

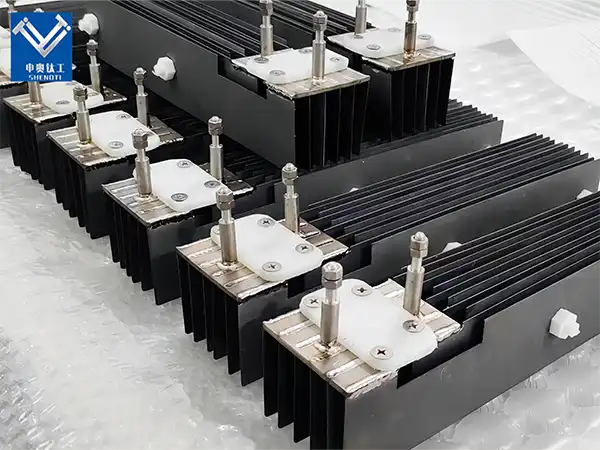

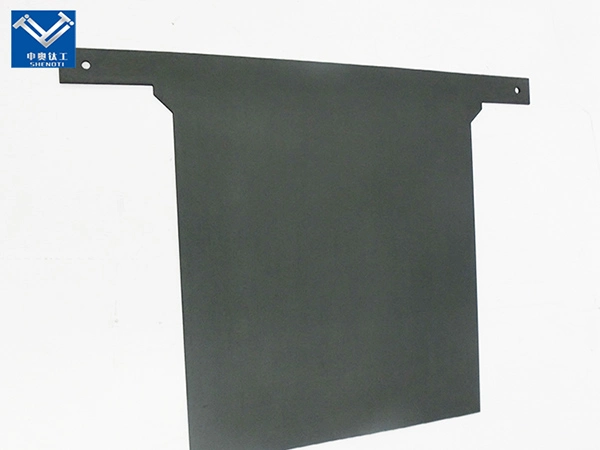

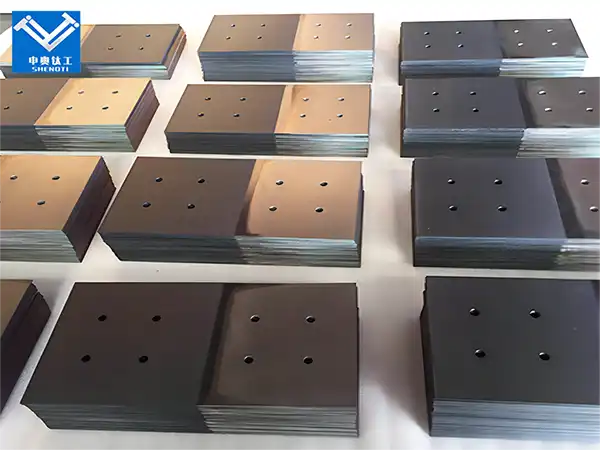

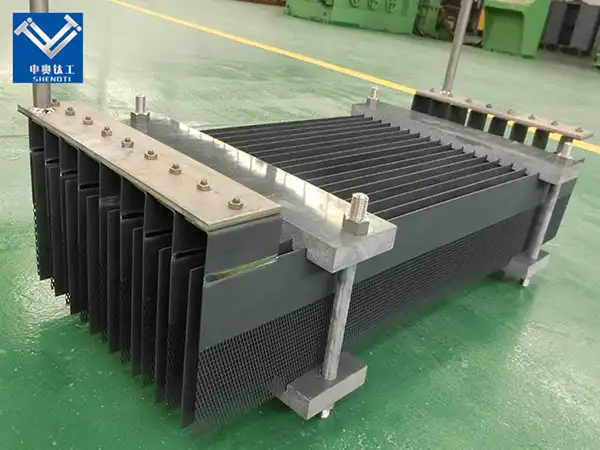

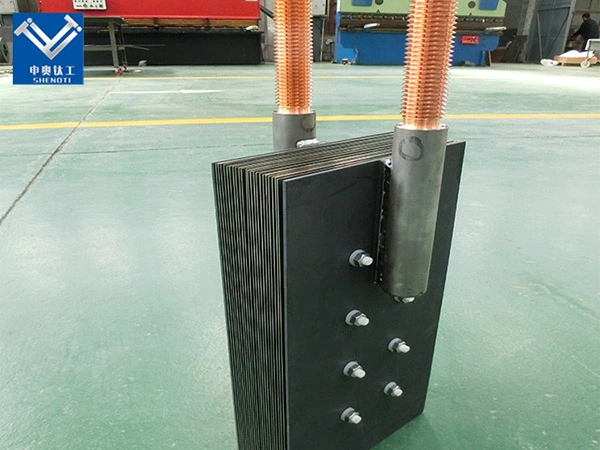

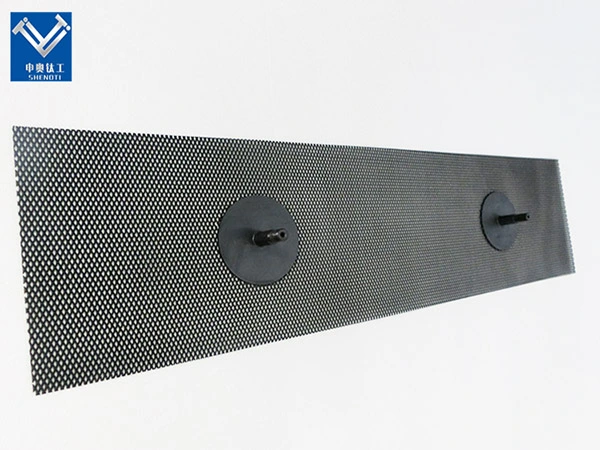

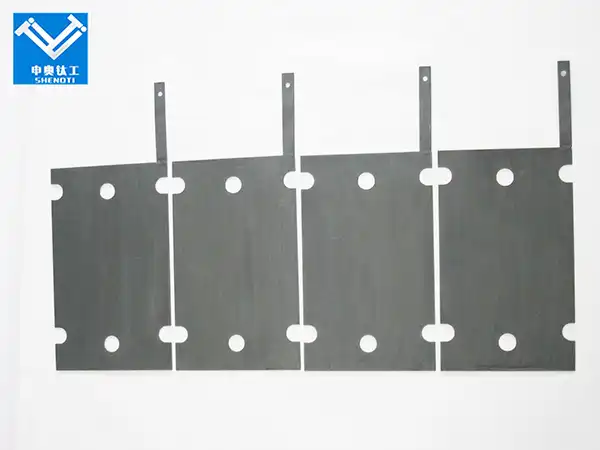

5. Flexible Design Options

Manufacturers can customize titanium anodes in mesh, plate, tubular, or rod forms to fit specific system configurations, from small on-site hypochlorite generators to large-scale desalination plants.

Applications of Titanium Anode for Electrolysis of Seawater

The versatility and durability of titanium anodes for electrolysis of seawater make them ideal for a wide range of applications across multiple industries.

1. Marine and Offshore Water Disinfection

Titanium anodes are used to generate sodium hypochlorite directly from seawater for sterilizing seawater cooling systems, ballast water, and offshore platforms. This prevents biofouling and ensures smooth operation of shipboard and coastal facilities.

2. Desalination Plants

In desalination systems, seawater electrolysis with titanium anodes is employed to produce disinfectant chlorine, ensuring the safety of freshwater output. The anode’s stability under continuous operation makes it ideal for these high-demand environments.

3. Power Plants and Cooling Water Systems

Power plants located near coastal areas use titanium anodes for seawater electrolysis to produce hypochlorite, preventing algae and bacterial growth in cooling circuits.

4. Municipal Water Treatment

By generating sodium hypochlorite on-site through electrolysis, water treatment facilities can avoid handling hazardous chlorine gas while achieving reliable disinfection results.

5. Hydrogen Production

When seawater is used as an electrolyte for hydrogen generation, titanium anodes serve as a robust and corrosion-resistant solution, paving the way for green hydrogen energy initiatives.

Real-World Use of Titanium Anodes for Seawater Electrolysis Case:

1: Offshore Platform in the Middle East

A large oil and gas company installed a titanium anode-based seawater electrolysis system to generate sodium hypochlorite for cooling water sterilization. The system has operated continuously for over seven years with minimal maintenance, maintaining 98% efficiency and significant energy savings.

2: Desalination Plant in Southeast Asia

A 100,000 m³/day desalination facility replaced its traditional graphite electrodes with MMO-coated titanium anodes. The upgrade improved chlorine generation efficiency by 25% and extended the electrode lifespan by 5 times.

3: Municipal Water Treatment in Europe

To meet environmental regulations, a European municipal plant adopted titanium anodes for seawater electrolysis to produce disinfectant chlorine on-site. This eliminated the need to transport hazardous chemicals, improving both safety and sustainability.

|

|

|

|

|

|

|

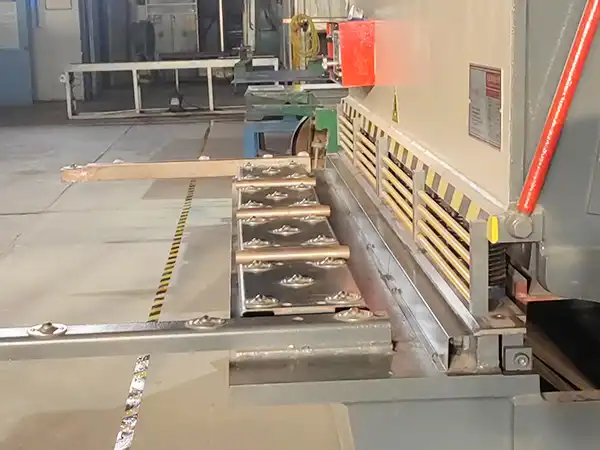

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Research and Innovation:With a dedicated R&D team, we ensure cutting-edge solutions that cater to evolving industrial demands.

- Proven Expertise:Over 17 years of experience delivering high-quality titanium anodes to global industries.

- Unmatched Quality:Adhering to strict production standards, we guarantee durable and reliable products.

- Customization Services:We provide tailored solutions for unique technical requirements and operational challenges.

- Timely Delivery and Support:Our robust logistics and dedicated customer service ensure seamless order fulfillment and after-sales assistance.

- OEM Services:Partner with us for private-label manufacturing and custom branding.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

1. How long does the titanium anode last?

The service life ranges from 5 to 20 years, depending on the application and operating conditions.

2. Can the anode dimensions be customized?

Yes, we offer fully customizable dimensions and designs to suit specific needs.

3. What maintenance is required for the anodes?

Minimal maintenance is needed. Regular cleaning ensures optimal performance.

4. Are these anodes environmentally friendly?

Yes, they are designed to promote energy efficiency and sustainability in industrial processes.

Contact Us

For professional support and inquiries about titanium anodes, reach out to us:

Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

We’re here to help you with the best solutions for your industrial needs.By combining high-quality materials, advanced technology, and customer-centric service, our Titanium Anode for Electrolysis of Seawater is the reliable choice for industries worldwide. Contact us today to enhance your operations with sustainable and efficient anode solutions!

YOU MAY LIKE

_1735536653204.webp)

_1735537191874.webp)

_1735537580980.webp)

_1735890168956.webp)

_1735890230062.webp)