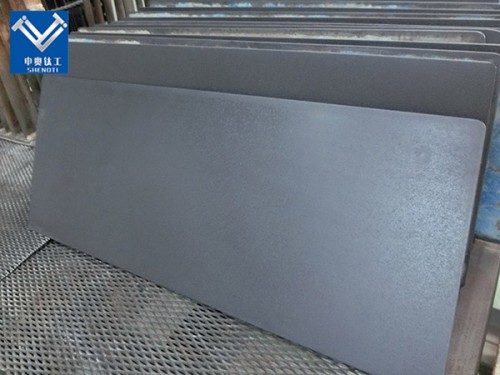

MMO Titanium Mesh Anode Introduction

MMO titanium mesh anode are advanced and highly durable electrodes designed for a wide range of electrolytic applications. Made from high-quality titanium substrates coated with a mixed metal oxide layer, these anodes offer exceptional performance in electrochemical processes, especially in harsh environments such as seawater desalination, electroplating, and wastewater treatment.

At Baoji City ShenAo Metal Materials Co., Ltd., we are committed to providing high-quality MMO Titanium Mesh Anodes that meet the demands of industries like chemical, energy, environmental protection, and more. Our products are engineered to deliver superior corrosion resistance, long-lasting service life, and enhanced efficiency in electrolytic applications.

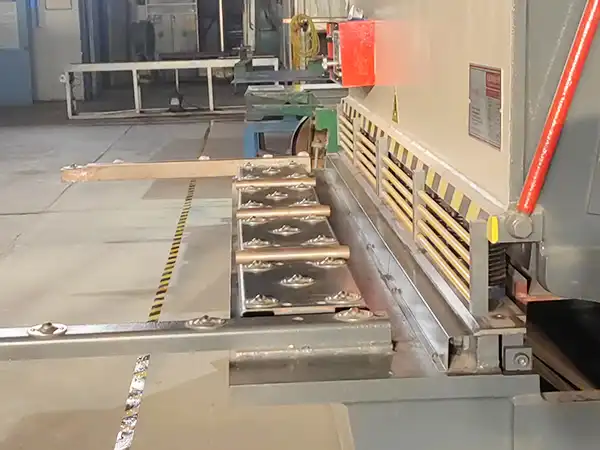

Manufacturing Process of MMO Titanium Mesh Anode

The production of an MMO titanium mesh anode involves precise steps to ensure high quality and performance.

1: Titanium Mesh Preparation

Commercially pure titanium (Grades 1 or 2) is selected as the substrate. The titanium mesh is cut and shaped according to customer specifications.

2: Surface Treatment

To improve coating adhesion, the titanium mesh undergoes surface cleaning, pickling, and activation. This step removes oxides and contaminants, preparing the surface for MMO coating.

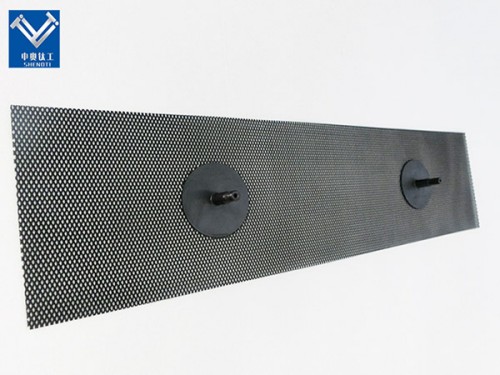

3: MMO Coating Application

A mixture of metal oxides (commonly ruthenium oxide, iridium oxide, or tantalum oxide) is applied onto the titanium surface using advanced techniques such as thermal decomposition or electrochemical deposition.

4: Heat Treatment

The coated titanium mesh is baked at high temperatures to ensure strong adhesion between the substrate and the coating, enhancing durability.

5: Quality Testing

Every MMO titanium mesh anode is subjected to rigorous tests for coating uniformity, adhesion, electrochemical performance, and dimensional accuracy.

This manufacturing process guarantees a product with stable performance, long service life, and suitability for a wide range of industrial environments.

Technical Specifications

Below are the key technical specifications of our product:

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of MMO Titanium Mesh Anode

1. High Durability:

Our MMO Titanium Mesh Anodes are known for their long-lasting performance, even in challenging conditions such as high temperatures and corrosive environments. The titanium substrate combined with the mixed metal oxide coating ensures high resistance to corrosion and extends the anode's operational life.

2. Excellent Electrolytic Performance:

These anodes provide stable electrochemical performance, making them ideal for continuous use in processes like electroplating, seawater desalination, and wastewater treatment. Their low overvoltage and high current efficiency help improve the overall efficiency of electrolysis systems.

3. Customizable Design:

We offer customization in terms of mesh size, coating thickness, and substrate material, allowing you to tailor the anodes to meet your specific requirements. This ensures the best performance for your application.

4. Low Maintenance and Cost-Effective:

Due to their high resistance to corrosion, MMO Titanium Mesh Anodes require minimal maintenance and have a long service life, reducing the need for frequent replacements and lowering operational costs.

5. Environmentally Friendly:

The use of titanium and mixed metal oxides in our anodes contributes to a more sustainable and eco-friendly solution for various electrolytic applications, supporting energy-saving and environmental protection efforts.

Industrial Applications of MMO Titanium Mesh Anode

The MMO titanium mesh anode is widely used across multiple industries due to its versatility and efficiency.

1. Water Treatment and Electrochlorination

One of the most common uses of MMO titanium mesh anodes is in the production of sodium hypochlorite through electrochlorination. This process is essential for disinfecting drinking water, swimming pools, and wastewater treatment systems.

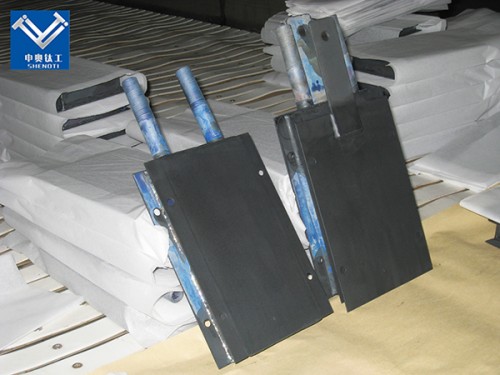

2. Cathodic Protection

In marine and underground structures, corrosion is a major concern. MMO titanium mesh anodes are used in impressed current cathodic protection (ICCP) systems to prevent corrosion of pipelines, storage tanks, and offshore platforms.

3. Electroplating and Metal Finishing

Electroplating requires precise current distribution and stability. The mesh design of MMO titanium mesh anodes ensures uniform plating in industries like electronics, jewelry, and automotive manufacturing.

4. Electrolysis Processes

MMO titanium mesh anodes are essential in electrolysis for chlorine, oxygen, and hydrogen generation. Their high stability makes them ideal for harsh electrolytic environments.

5. Mining and Metallurgy

In the extraction and refining of metals such as copper, zinc, and manganese, MMO titanium mesh anodes provide long-term efficiency and reduce operational costs.

MMO Titanium Mesh Anode Applications Case

1: Seawater Desalination Plant

An international desalination project integrated MMO titanium mesh anodes into its electrochlorination units. The result was improved chlorine generation efficiency and reduced maintenance costs.

2: Underground Pipeline Protection

A large oil company adopted MMO titanium mesh anodes for ICCP systems, significantly extending pipeline lifespan and lowering corrosion-related risks.

3: Electroplating Factory

An electronics plating facility upgraded its electrode system to MMO titanium mesh anodes, achieving better plating uniformity, increased productivity, and reduced downtime.

|

|

|

|

|

|

|

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

At Baoji City ShenAo Metal Materials Co., Ltd., we take pride in our ability to deliver high-quality, customized product for various industries. Here’s why you should choose us:

1. Research and Innovation:

We have an experienced R&D team that is dedicated to exploring new technologies and applications for products. Our commitment to innovation allows us to offer cutting-edge solutions that meet your specific needs.

2. Striving for Excellence:

We follow stringent quality control processes to ensure that every anode we produce meets the highest industry standards. Whether you need small-scale testing or large-scale production, we deliver on time and maintain the highest quality.

3. Customized Product Services:

We offer customized solutions according to each client's particular requirements.In order to create products that satisfy particular performance and technical requirements, our team works closely with clients.

4. OEM Services:

We also offer OEM services, producing the products to your exact specifications.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: What is the service life of the products?

A1: Our products have a service life of 10-20 years, depending on the specific application and operating conditions.

Q2: Can the anodes be customized?

A2: Yes, we offer customization in mesh size, coating thickness, and substrate material to suit your specific needs.

Q3: Are these anodes suitable for use in seawater desalination?

A3: Yes, our products are highly resistant to seawater corrosion, making them ideal for seawater desalination applications.

Q4: What industries can benefit from MMO Titanium Mesh Anodes?

A4: Our anodes are widely used in industries such as chemical, energy, environmental protection, electrical, pharmaceutical, and marine applications.

Contact Details

For more information or to request a quote, feel free to reach out to us:

Company Name: Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact Person: Wang Shujuan

Phone: +86 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

We are always here to provide the best solutions for your metal material needs!

YOU MAY LIKE

_1735356385558.webp)