Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

Industrial wastewater treatment is a crucial process for sustainable manufacturing, and the choice of electrode material plays a decisive role in its efficiency and longevity. Among various electrode types, Titanium anodes for industrial wastewater treatment have emerged as the preferred solution thanks to their superior corrosion resistance, high current efficiency, and long service life.

What Are Titanium Anodes for Industrial Wastewater Treatment?

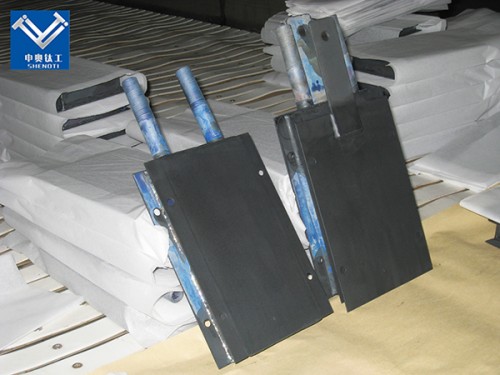

Titanium anodes for industrial wastewater treatment are electrochemical electrodes made primarily from high-purity titanium substrates coated with precious metal oxides such as ruthenium, iridium, or platinum. These coatings act as active catalytic layers, enabling efficient oxidation reactions that degrade organic pollutants, heavy metals, and toxic substances in wastewater. Baoji City ShenAo Metal Materials Co., Ltd., our Titanium anodes for industrial wastewater treatment is crafted with advanced coating technology and premium materials, making them ideal for industries prioritizing corrosion resistance and operational longevity.

Technical Specifications

The technical details of our titanium anodes are outlined below for reference:

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Titanium Anodes in Industrial Wastewater Treatment

The widespread adoption of Titanium anodes for industrial wastewater treatment is driven by their combination of performance, durability, and environmental compatibility.

1. High Oxidation Efficiency

Titanium anodes can generate powerful oxidizing agents directly at the electrode surface, allowing the breakdown of complex organics without adding external chemicals.

2. Low Maintenance and Long Life

With self-passivating coatings, titanium anodes resist fouling and corrosion, significantly reducing downtime and replacement costs.

3. Eco-Friendly Technology

Unlike traditional chemical treatments, titanium anode-based electrolysis produces minimal sludge and eliminates secondary pollution.

4. Energy Saving

The low cell voltage and high catalytic activity of MMO or platinum coatings reduce energy consumption during wastewater electrolysis.

5. Adaptability

Titanium anodes can be customized in shapes (mesh, plate, rod, or tubular) and sizes to fit various reactors and flow systems.

Applications of Titanium Anodes in Industrial Wastewater Treatment

Titanium anodes for industrial wastewater treatment are widely applied across multiple sectors that produce high-load or toxic effluents.

1. Electrochemical Oxidation Systems

Titanium anodes are at the core of electrochemical oxidation (EO) and electrocoagulation systems, where they generate active oxidants like hydroxyl radicals and chlorine species to decompose complex organic molecules.

2. Treatment of Electroplating and Metal Finishing Wastewater

In industries like electroplating, PCB manufacturing, and metal surface treatment, titanium anodes help remove heavy metals such as chromium, nickel, and copper from wastewater, ensuring compliance with environmental discharge standards.

3. Pharmaceutical and Chemical Wastewater

Titanium anodes effectively degrade pharmaceutical residues, dyes, phenols, and surfactants, making them valuable for chemical, dyeing, and pharmaceutical wastewater treatment.

4. Landfill Leachate Treatment

Due to their strong oxidation ability, titanium anodes are used to treat landfill leachate — one of the most challenging types of industrial wastewater — breaking down refractory compounds like humic acids.

5. Recycling and Resource Recovery

In some systems, titanium anodes also enable metal ion recovery through electrolysis, turning waste streams into valuable resources, such as copper and nickel reuse.

Titanium Anodes for Industrial Wastewater Treatment in Action Case :

1. Electroplating Wastewater in East Asia

A major electronics manufacturer adopted MMO-coated titanium anodes to treat cyanide-bearing wastewater. The anodes achieved over 95% removal efficiency for cyanide and reduced COD by 80%, cutting treatment costs by 40%.

2. Pharmaceutical Factory in Europe

Platinum-coated titanium anodes were installed in an advanced oxidation system to treat antibiotic-laden wastewater. The system achieved near-complete degradation of complex organic compounds with minimal maintenance over three years.

3. Landfill Leachate in the Middle East

Titanium anodes with mixed IrO₂–Ta₂O₅ coatings were applied to treat heavily polluted leachate. COD levels were reduced from 6,000 mg/L to below 200 mg/L, meeting strict environmental regulations.

|

|

|

|

|

|

|

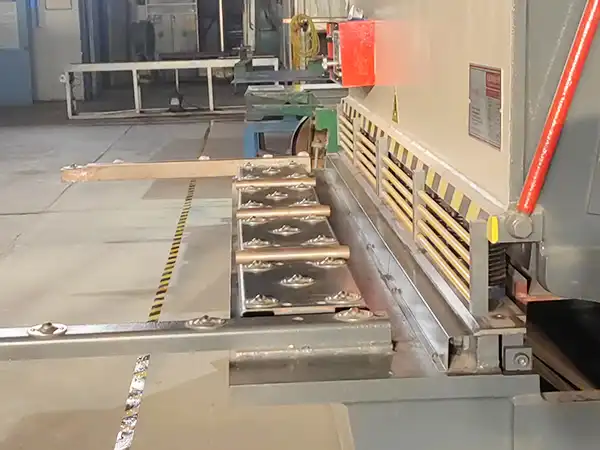

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Baoji City ShenAo Metal Materials Co., Ltd.?

As a leading manufacturer specializing in Titanium anodes for industrial wastewater treatment, Baoji City ShenAo Metal Materials Co., Ltd. has over a decade of expertise in non-ferrous metal and electrode technology.

Our Capabilities Include:

Custom manufacturing of MMO, platinum, and lead dioxide coated titanium anodes

Advanced coating and heat treatment facilities ensuring consistent quality

Engineering support for reactor design and wastewater treatment system integration

Global supply capability with strict ISO-certified production processes

Every titanium anode produced by ShenAo undergoes rigorous inspection to guarantee performance, coating uniformity, and corrosion resistance — ensuring reliable operation in the harshest wastewater environments.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: What makes titanium anodes suitable for wastewater treatment?

Titanium anodes for industrial wastewater treatment are highly durable and resistant to corrosion, ensuring long-term performance in harsh chemical environments. They also offer superior conductivity, making them ideal for electrochemical processes.

Q2: Can the anodes be customized for specific industries?

Yes, we provide fully customizable anodes tailored to your industry’s requirements, including dimensions, coatings, and shapes.

Q3: How long do titanium anodes typically last?

The service life ranges from 3 to 10 years, depending on the operating environment and maintenance.

Q4: Do you offer technical support for installation and operation?

Absolutely. Our team provides comprehensive technical guidance and support to ensure seamless integration into your systems.

Contact Us

At Baoji City ShenAo Metal Materials Co., Ltd., we are committed to delivering high-performance titanium anodes tailored to your industrial wastewater treatment needs.

- Name: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- E-Mail: zh@baojiti.com.cn

For more information or to place an order about titanium anodes for industrial wastewater treatment, reach out to us today!

YOU MAY LIKE