In the field of electrochemical engineering, the excellent corrosion resistance, high current efficiency, and long service life of precious metal oxide-coated anodes (often abbreviated as MMO or DSA anodes) have made them an indispensable technology.

Baoji Shenao Metal Materials Co., Ltd. is a manufacturer of precious metal oxide-coated anodes. The company combines advanced coating technology with precision metal processing to provide high-performance anodes tailored for the harshest electrochemical environments.

What are precious metal oxide-coated anodes?

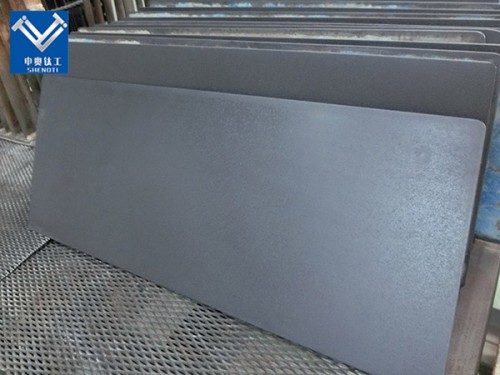

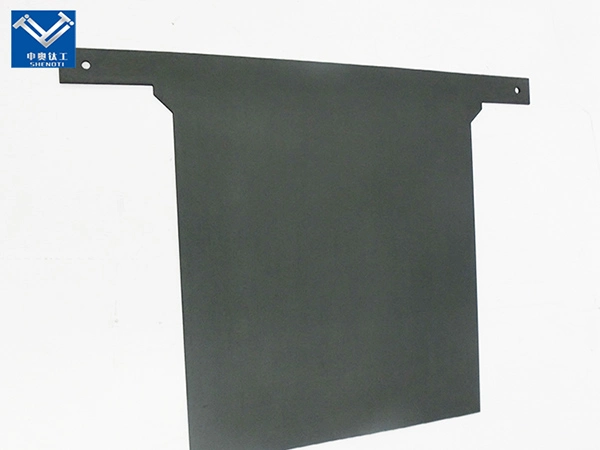

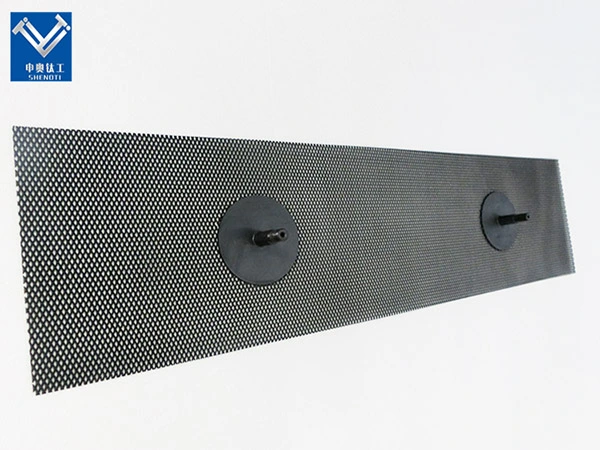

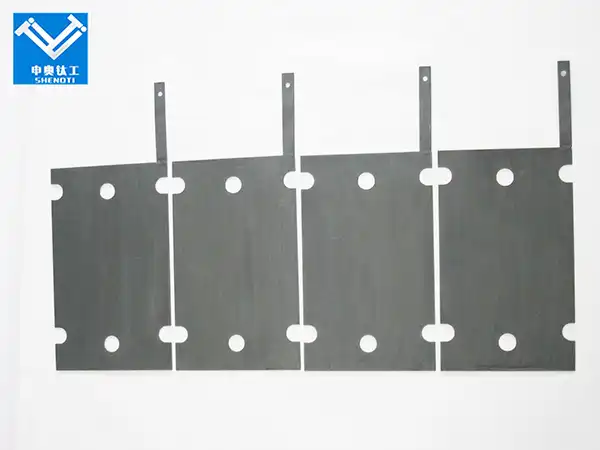

Precious metal oxide-coated anodes are electrochemical electrodes composed of a titanium substrate coated with a combination of various precious metal oxides, such as iridium oxide (IrO₂), ruthenium oxide (RuO₂), and platinum oxide (PtO₂). The titanium substrate provides mechanical strength and corrosion resistance, while the metal oxide coating acts as a catalytic and conductive layer, responsible for electrochemical activity.

Technical Parameters of Precious Metal Oxide Coated Anodes

|

Parameter |

Typical Range |

|

Base Material |

Titanium (Gr1/Gr2) |

|

Coating Composition |

IrO₂, RuO₂, PtO₂, TiO₂ |

|

Operating Current Density |

500–10,000 A/m² |

|

Coating Thickness |

3–10 μm |

|

Operating Temperature |

Up to 80°C (continuous) |

|

Service Life |

5–15 years (depending on conditions) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key Features and Advantages of Precious Metal Oxide Coated Anodes

1. Exceptional Corrosion Resistance

The noble metal oxides used in these anodes exhibit outstanding chemical stability in aggressive electrolytes, including acidic, alkaline, and chloride-containing environments. This ensures extended operational life even under high current densities.

2. High Current Efficiency

The catalytic surface of the precious metal oxide coated anode reduces overpotential and enhances electrochemical reaction rates. This efficiency translates into lower energy consumption and reduced operational costs for end users.

3. Long Service Life

The combination of a robust titanium substrate and a precisely formulated metal oxide coating provides superior durability. Depending on the electrolyte composition and current density, service life can exceed 10 years with minimal degradation.

4. Dimensional Stability

Unlike graphite or lead anodes, precious metal oxide coated anodes retain their original shape and dimensions, ensuring consistent electrical performance and uniform current distribution.

5. Environmental Sustainability

These anodes eliminate the risk of heavy metal contamination and reduce waste generation, aligning with global trends toward sustainable industrial processes.

Industrial Applications of Precious Metal Oxide Coated Anodes

1. Electrochlorination and Water Treatment

In seawater or brine electrolysis systems, precious metal oxide coated anodes efficiently generate chlorine and sodium hypochlorite for disinfection. Their anti-corrosive properties make them ideal for continuous operation in saline environments.

2. Electroplating and Surface Finishing

These anodes provide uniform current distribution and consistent plating quality, making them suitable for applications such as nickel plating, gold plating, and chrome plating.

3. Metal Electrowinning

In copper, zinc, cobalt, and manganese electrowinning, precious metal oxide coated anodes deliver stable performance and reduce power consumption, significantly lowering production costs.

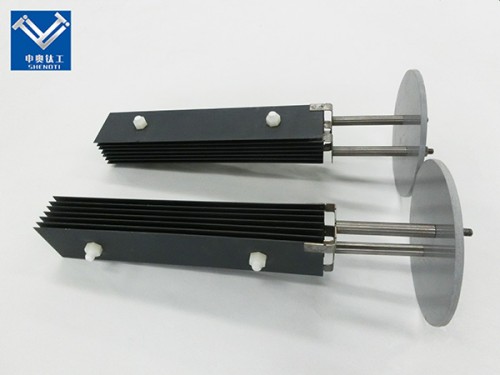

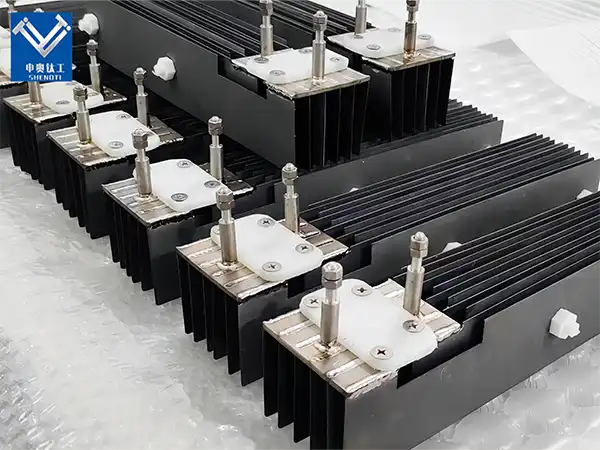

4. Cathodic Protection Systems

Used for protecting steel structures like pipelines, storage tanks, and marine platforms from corrosion. The anodes provide steady current output with minimal maintenance requirements.

5. Wastewater and Industrial Effluent Treatment

The high catalytic activity of MMO coatings allows the oxidation of organic pollutants and cyanides, enabling efficient electrochemical wastewater purification.

6. Hydrogen and Oxygen Generation

In hydrogen production by water electrolysis, iridium oxide coated titanium anodes serve as durable oxygen evolution electrodes, offering high efficiency and stability.

Proven Case :

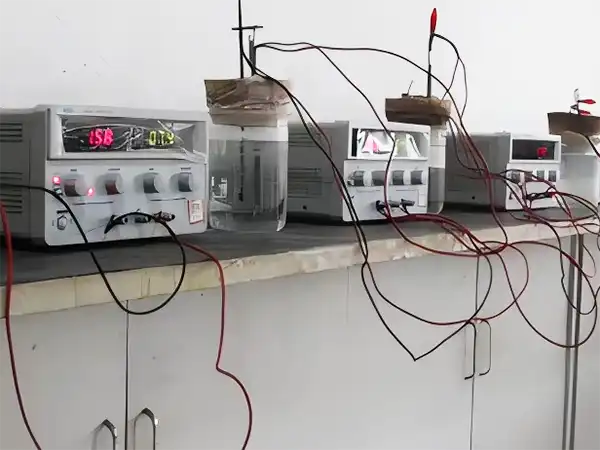

1: Wastewater Treatment Plant – China

A municipal wastewater facility replaced graphite electrodes with our ruthenium-iridium oxide coated anodes, achieving a 40% increase in oxidation efficiency and 60% reduction in maintenance costs over two years.

2: Seawater Electrochlorination System – Middle East

Our MMO coated titanium anodes were used in a desalination plant to generate sodium hypochlorite for biofouling control. The system operated continuously for over 20,000 hours with no coating degradation.

3: Metal Electrowinning – South America

For a copper refinery, our iridium oxide coated anodes improved current efficiency by 8% and maintained structural integrity after 18 months of heavy-duty operation.

|

|

|

|

|

|

|

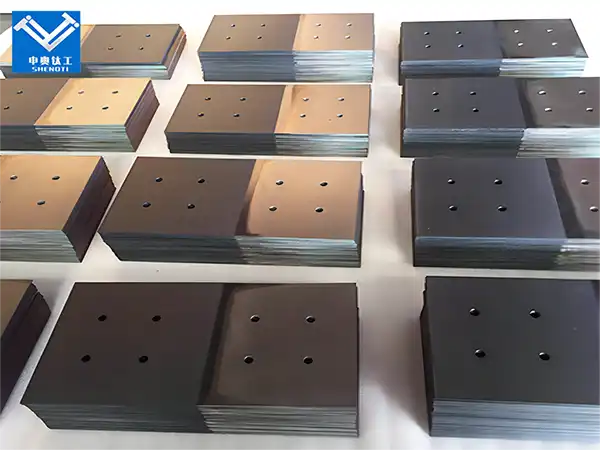

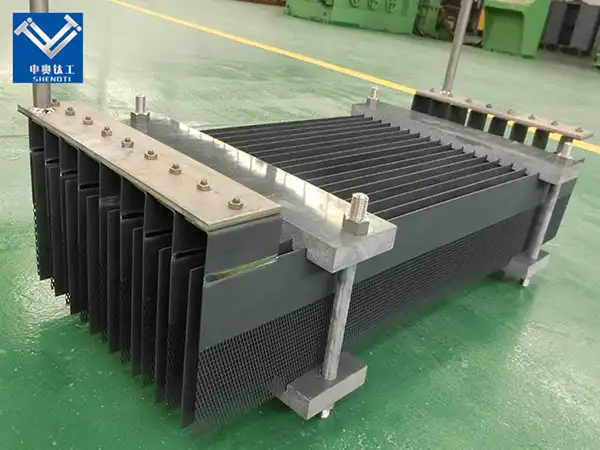

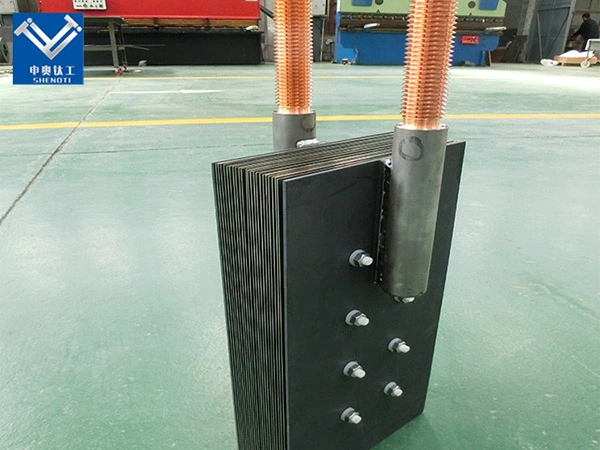

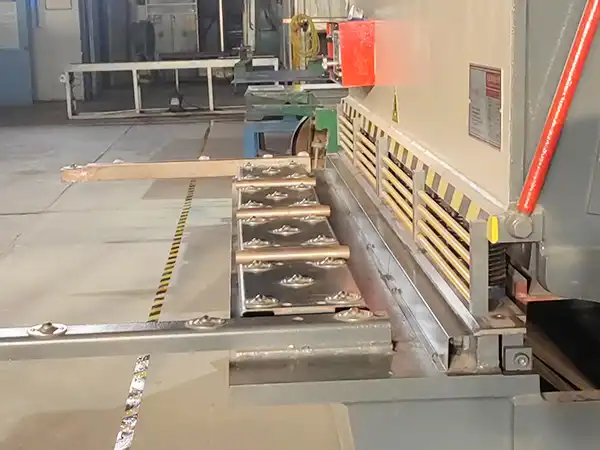

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Our Precious Metal Oxide Coated Anodes?

Baoji Shenao Metal Materials Co., Ltd., a trusted manufacturer of MMO anodes, provides complete design, production, and customization services to industrial customers worldwide. Our anodes are renowned for their uniform coating, excellent conductivity, and durability.

Our Core Competencies

In-house thermal decomposition coating facility

Customized oxide formulations based on application requirements

ISO-certified quality management system

Global supply capability and technical support

Studies: Proven Performance in the Field

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q: What factors affect the service life of the anodes?

A: Service life depends on the operating environment, current density, and specific application. Proper maintenance can extend longevity.

Q: Can the anodes be customized?

A: Yes, we provide fully customizable solutions, including material, dimensions, and coatings.

Q: What industries are these anodes best suited for?

A: They are ideal for wastewater treatment, chemical processing, desalination, and cathodic protection, among others.

Contact Us

For inquiries and tailored solutions, reach out to us today:

Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Experience unparalleled service and expertise with Baoji City ShenAo Metal Materials Co., Ltd.—your Precious metal oxide coated anodes and advanced materials.

YOU MAY LIKE