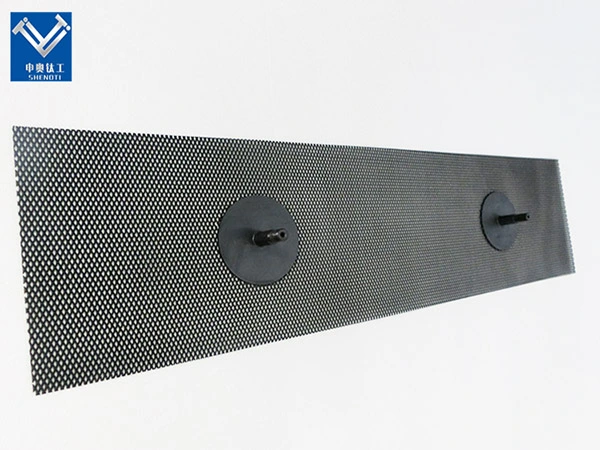

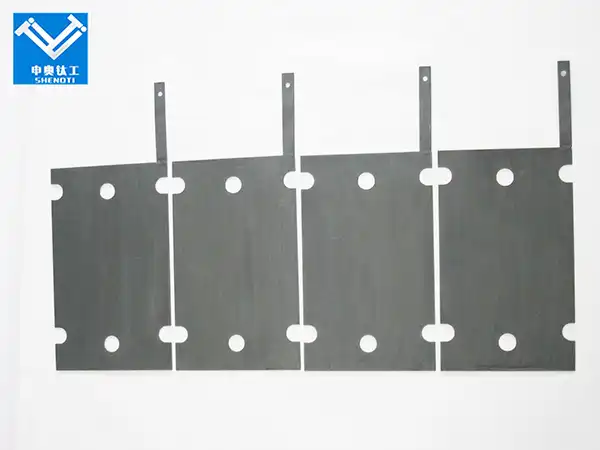

A titanium anode for electrolyzing salt water is a specially designed electrode made of a titanium substrate coated with precious metal oxides such as ruthenium (RuO₂), iridium (IrO₂), or mixed metal oxides (MMO). Its primary function is to conduct current and catalyze the electrolytic decomposition of sodium chloride (NaCl) in brine or seawater, producing chlorine gas, hydrogen, and sodium hydroxide.

The general electrolysis reaction is:

2NaCl+2H2O→Cl2↑+H2↑+2NaOH2NaCl + 2H_2O → Cl_2↑ + H_2↑ + 2NaOH2NaCl+2H2O→Cl2↑+H2↑+2NaOHHere, the titanium anode serves as the oxidation electrode, promoting the evolution of chlorine gas while resisting severe corrosion from chloride ions and high voltage.

Technical Parameters of Titanium Anode for Electrolyzing Salt Water

|

Parameter |

Typical Value |

|

Substrate Material |

Titanium (Grade 1 or Grade 2) |

|

Coating Composition |

RuO₂ + IrO₂ or MMO |

|

Coating Thickness |

10–20 μm |

|

Current Density |

1000–5000 A/m² |

|

Operating Temperature |

25–60°C |

|

Service Life |

5–10 years |

|

Electrolysis Medium |

Brine or Seawater |

|

Chlorine Evolution Potential |

< 1.1 V vs. Ag/AgCl |

These parameters can be customized based on the client’s specific operating environment and electrochemical requirements.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key Features and Advantages of Titanium Anode for Electrolyzing Salt Water

1. Excellent Corrosion Resistance

Titanium itself forms a passive oxide film, while the noble metal oxide coating further enhances its resistance to chlorine and alkaline environments, ensuring long service life even in harsh seawater.

2. High Electrochemical Efficiency

The catalytic coating provides low overpotential for chlorine evolution, significantly reducing power consumption during electrolysis and improving operational efficiency.

3. Long Service Life

Thanks to stable coating structures, the titanium anode for electrolyzing salt water can maintain performance for over 5–10 years depending on usage conditions, minimizing replacement costs and downtime.

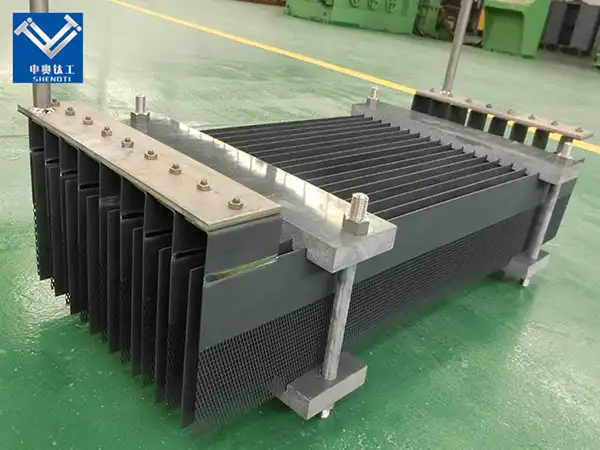

4. Uniform Current Distribution

The precisely engineered coating ensures even current flow and chlorine generation across the anode surface, which is critical for process stability in large-scale electrolysis systems.

5. Environmental and Economic Benefits

Unlike graphite or lead-based electrodes, titanium anodes produce no toxic byproducts, making them environmentally friendly and suitable for sustainable industrial production.

Applications of Titanium Anode for Electrolyzing Salt Water

1. Chlor-Alkali Industry

The titanium anode for electrolyzing salt water is the heart of chlor-alkali plants producing chlorine (Cl₂), hydrogen (H₂), and sodium hydroxide (NaOH). Its stable chlorine evolution potential ensures efficient production with reduced energy consumption.

2. Seawater Electrolysis and Desalination

In seawater treatment plants, titanium anodes are used to generate chlorine for biological sterilization and anti-fouling of pipelines and membranes. Their long lifespan and chemical stability make them ideal for continuous marine operations.

3. Electrolyzed Water Generators

Electrolyzed water systems used for disinfection in food processing, hospitals, and swimming pools rely on titanium anodes to produce hypochlorous acid (HOCl) safely and efficiently.

4. Wastewater Treatment

Titanium anodes are employed in electrochemical oxidation systems to decompose organic pollutants, cyanides, and ammonia nitrogen compounds. They help achieve high-efficiency oxidation without additional chemicals.

5. Cathodic Protection and Marine Engineering

Titanium anodes coated with MMO are also applied in cathodic protection systems for ships, offshore platforms, and seawater pipelines, preventing corrosion and extending equipment lifespan.

Industrial Applications of Titanium Anodes Case:

1. Seawater Chlorination System in Coastal Power Plant

A coastal thermal power plant adopted titanium anodes for its seawater electrolysis system to prevent biofouling in cooling pipelines. After installation, the plant achieved stable chlorine generation efficiency above 90% and reduced maintenance frequency by 50%.

2. Wastewater Treatment Plant for Textile Industry

In an electrochemical oxidation setup, titanium anodes helped break down dye molecules, achieving color removal efficiency above 95% and COD reduction of 80%, demonstrating excellent performance in organic wastewater treatment.

3. Electrolyzed Water Disinfection System

Food processing factories use titanium anodes to generate hypochlorous acid for surface and equipment disinfection, providing a safe, chemical-free sanitation solution that meets food safety standards.

|

|

|

|

|

|

|

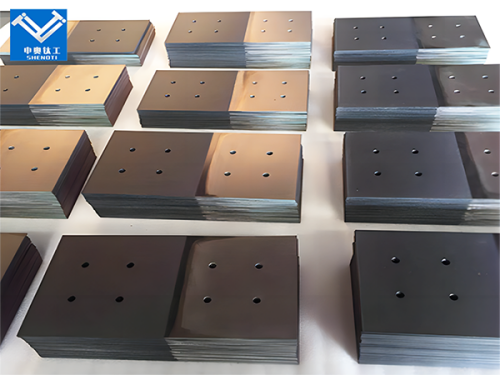

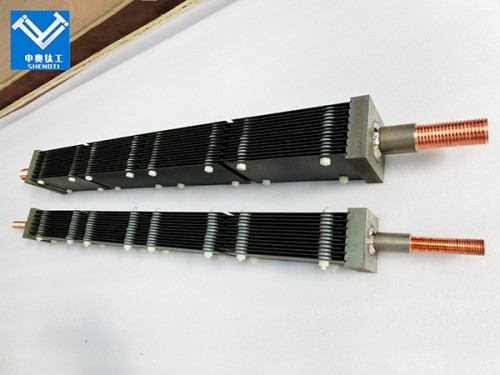

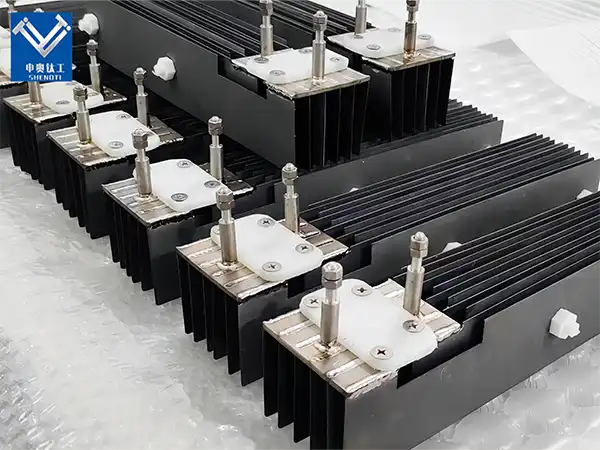

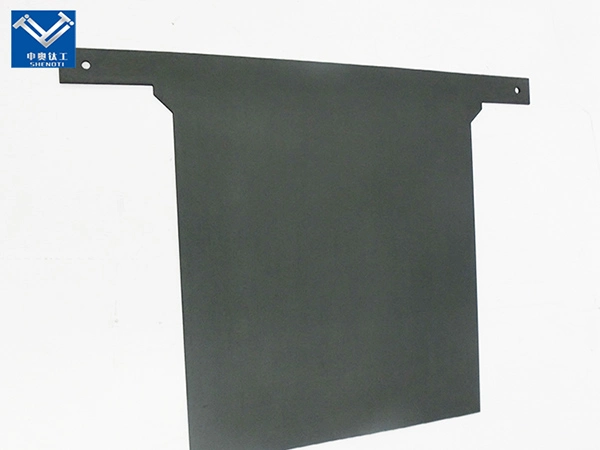

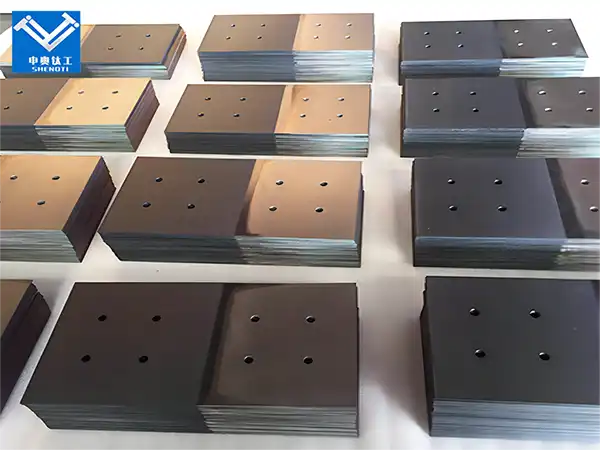

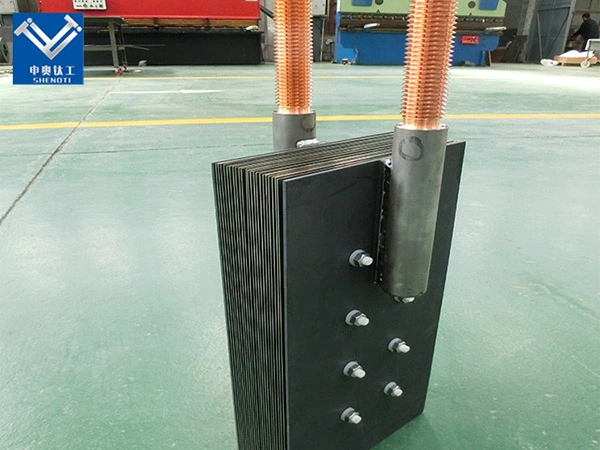

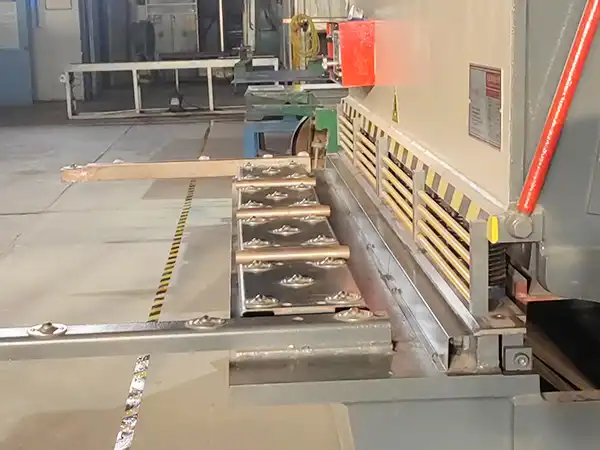

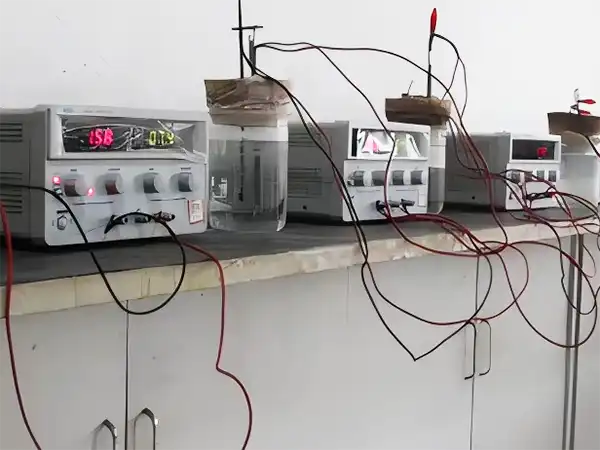

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Titanium Anode for Electrolyzing Salt Water from Professional Manufacturers

Selecting a high-quality titanium anode for electrolyzing salt water from a reputable supplier ensures reliability, efficiency, and long-term cost-effectiveness. Professional manufacturers offer several advantages:

Advanced Coating Technology

Using modern thermal decomposition and nano-coating techniques, manufacturers achieve uniform coating microstructures and optimized catalytic activity.

Strict Quality Control

From raw titanium inspection to final coating performance testing, every production step is strictly monitored to meet ISO and ASTM standards.

Tailored Design Solutions

Manufacturers provide customized electrode dimensions, coating formulations, and mounting structures according to different electrolyzer models and operating conditions.

Global Technical Support

Reliable suppliers also offer after-sales services, including installation guidance, performance testing, and technical consultation, ensuring smooth operation throughout the product’s lifecycle.

OEM Services

We provide customized OEM services, allowing you to personalize titanium anodes based on your project’s unique requirements. From dimensions to coatings, we deliver tailored solutions with precision and efficiency.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is the typical service life of your titanium anodes?

A: Depending on usage conditions and coating type, our anodes last between 3 to 10 years.

Q2: Can the dimensions of the anodes be customized?

A: Yes, we provide fully customizable dimensions and designs to fit your system.

Q3: Do you offer technical support?

A: Absolutely! Our team provides comprehensive support, from installation guidance to maintenance tips.

Contact Details

We’re here to provide expert guidance and high-quality products tailored to your needs. Contact us today for inquiries and orders.

- Company: Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Our titanium anode for electrolyzing salt water combines advanced technology, superior materials, and a customer-centric approach to deliver unparalleled performance. Whether for seawater desalination, wastewater treatment, or other industrial applications, our anodes are the optimal choice for efficiency, durability, and sustainability.

YOU MAY LIKE