In modern electrochemical industries, the DSA coated titanium anode (Dimensionally Stable Anode) has become one of the most critical components for improving efficiency, durability, and product quality. By combining the mechanical strength and corrosion resistance of titanium with the superior electrochemical activity of DSA coatings, this anode offers unmatched performance across various industrial applications—from wastewater treatment to metal electroplating and chlorine evolution.

What is a DSA Coated Titanium Anode?

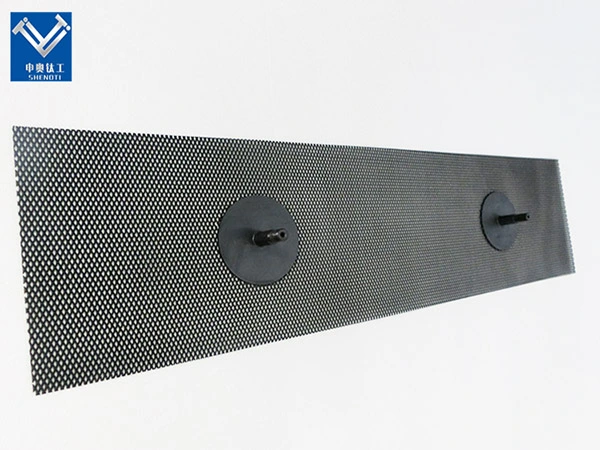

A DSA coated titanium anode refers to a titanium substrate that has been coated with a mixed metal oxide (MMO) layer, typically containing oxides of ruthenium (RuO₂), iridium (IrO₂), tantalum (Ta₂O₅), or titanium (TiO₂).

The term “DSA,” or Dimensionally Stable Anode, highlights its ability to maintain shape and dimension even after prolonged operation. Unlike graphite or lead-based anodes that degrade or deform, DSA coated titanium anodes retain structural stability, offering consistent current distribution and extended service life.

Technical Parameters of DSA Coated Titanium Anodes

|

Parameter |

Typical Range |

|

Base Material |

Titanium (Grade 1 or 2) |

|

Coating Type |

RuO₂–TiO₂, IrO₂–Ta₂O₅, RuO₂–IrO₂–TiO₂ |

|

Coating Thickness |

5–20 µm |

|

Operating Current Density |

100–10000 A/m² |

|

Operating Temperature |

≤ 80°C |

|

Service Life |

2–10 years (depending on medium and current) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key advantages of DSA Coated Titanium Anode

1. Excellent Corrosion Resistance

Titanium itself forms a natural oxide layer that prevents corrosion in aggressive electrolytes. The addition of DSA coatings further enhances this resistance, ensuring stable performance in acidic and alkaline environments.

2. High Electrochemical Activity

The mixed metal oxide coating significantly reduces the overpotential for key reactions, such as chlorine and oxygen evolution. This leads to lower energy consumption and higher process efficiency.

3. Dimensional Stability

As the name suggests, dimensionally stable anodes do not deform under electrical or thermal stress, which means constant anode spacing and uniform current distribution during long-term operation.

4. Long Service Life

The combination of a robust titanium base and durable DSA coating results in an exceptionally long operational lifespan, even under harsh industrial conditions.

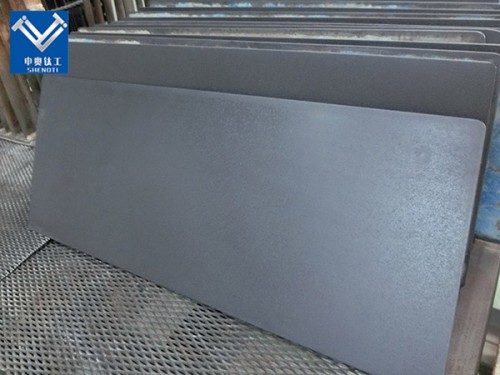

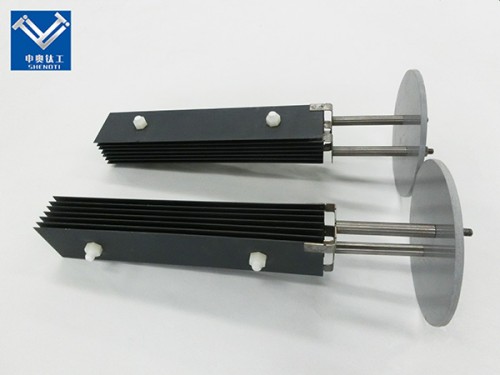

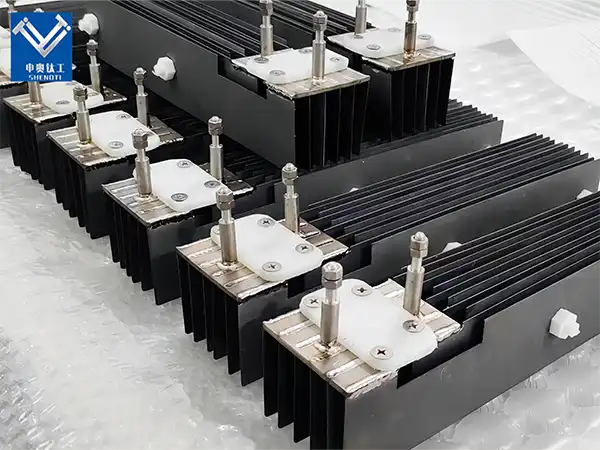

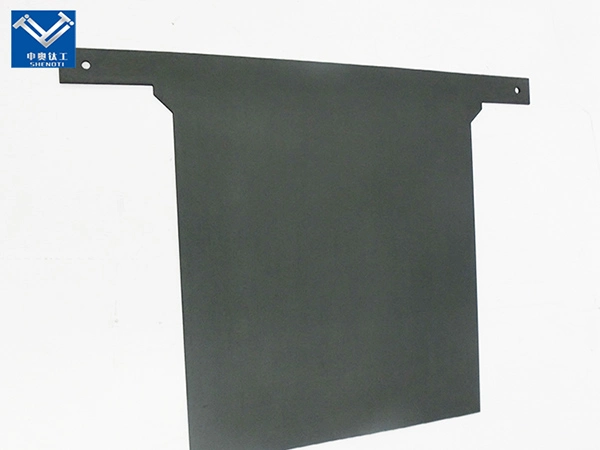

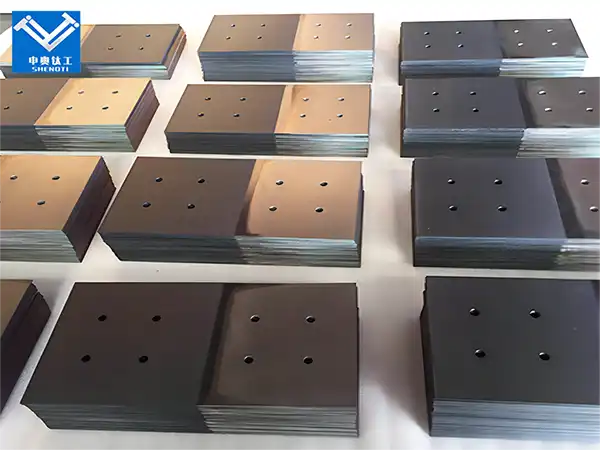

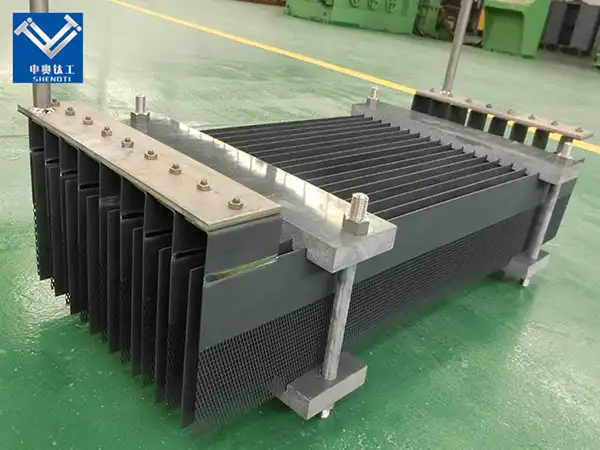

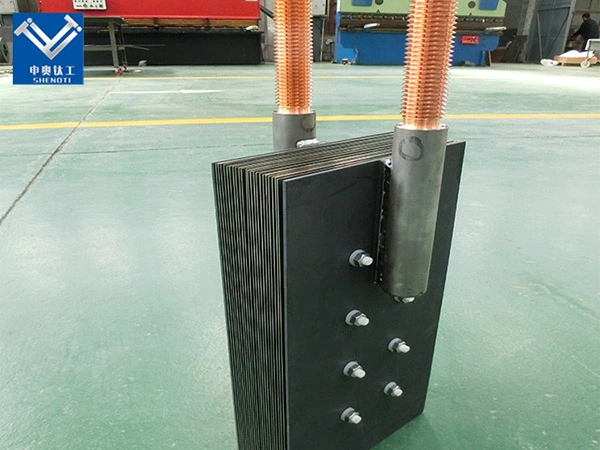

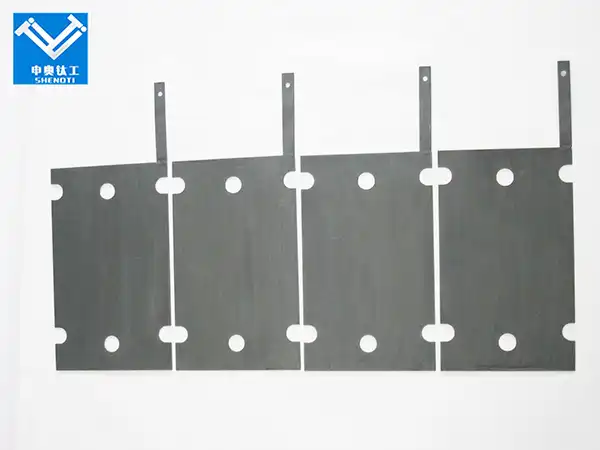

5. Customizable Design

DSA coated titanium anodes can be fabricated in various shapes — such as plates, meshes, rods, or tubes — depending on the specific electrochemical cell design and process requirements.

Applications of DSA Coated Titanium Anode

1. Electroplating Industry

In metal finishing, DSA coated titanium anodes replace traditional lead or graphite anodes. They provide stable current output, uniform plating thickness, and reduced contamination, ensuring high-quality coatings in copper, nickel, and zinc electroplating processes.

2. Wastewater Treatment

DSA coated titanium anodes are used for electrochemical oxidation of organic pollutants and ammonia nitrogen. Their superior oxygen evolution ability makes them efficient for treating industrial and municipal wastewater.

3. Chlor-Alkali Production

One of the largest applications of DSA coated titanium anodes is in chlorine and caustic soda production. They ensure high current efficiency and low maintenance costs, improving the economic performance of large-scale plants.

4. Cathodic Protection

In marine structures, storage tanks, and pipelines, DSA coated titanium anodes act as long-lasting impressed current anodes, preventing corrosion in submerged or buried metal structures.

5. Electrolysis for Hydrogen and Oxygen Generation

Due to their excellent stability and catalytic activity, DSA coated titanium anodes are increasingly used in water electrolysis systems for producing hydrogen and oxygen, a key process in the renewable energy industry.

Case Real-World Applications of DSA Coated Titanium Anodes:

1: Electrochemical Wastewater Treatment Plant

A plating factory in Southeast Asia adopted IrO₂–Ta₂O₅ DSA coated titanium anodes to treat wastewater containing cyanide and heavy metals. The system achieved over 95% COD removal efficiency, reducing environmental impact and treatment costs.

2: Chlorine Evolution in Chemical Manufacturing

In a large-scale chlor-alkali plant, RuO₂–TiO₂ coated titanium anodes replaced lead-based anodes. The upgrade resulted in 20% lower energy consumption and a service life exceeding five years under continuous operation.

3: Hydrogen Production via Water Electrolysis

A renewable energy company integrated DSA coated titanium anodes into their hydrogen generation system, achieving stable current efficiency and long-term durability in alkaline electrolytes.

|

|

|

|

|

|

|

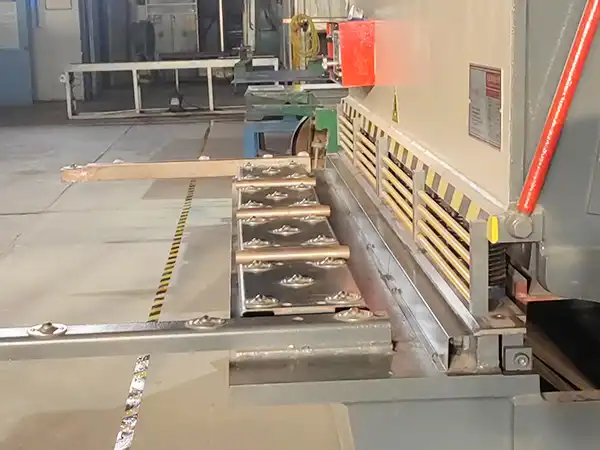

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Research and Innovation:Backed by a dedicated R&D team, we continually refine our processes and expand application possibilities.

- Excellent Reputation:With 17 years of industry experience, we are trusted for our consistent quality and customer-centric approach.

- Striving for Excellence:We uphold rigorous production standards and maintain a robust quality management system, ensuring that every product meets the highest benchmarks of performance, safety, and durability. Our commitment to excellence guarantees dependable results and customer satisfaction in every project we undertake.

- Customized Services:We understand that every client has unique technical and operational needs. As such, we offer customized solutions tailored to meet specific requirements, ensuring that our products and services align perfectly with your business objectives and operational conditions.

- Timely Delivery & Support:Efficient production and logistics minimize lead times, complemented by comprehensive after-sales service.

- OEM Services:We offer private labeling and manufacturing to meet your unique branding requirements.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

-

What is the lifespan of a Anode of titanium covered with DSA?

The service life ranges from 5 to 10+ years, depending on the operating conditions.

-

Can the anode be customized for specific applications?

Yes, we provide custom dimensions and coatings based on your requirements.

-

What industries benefit the most from these anodes?

They are widely used in water treatment, electrowinning, and energy sectors.

-

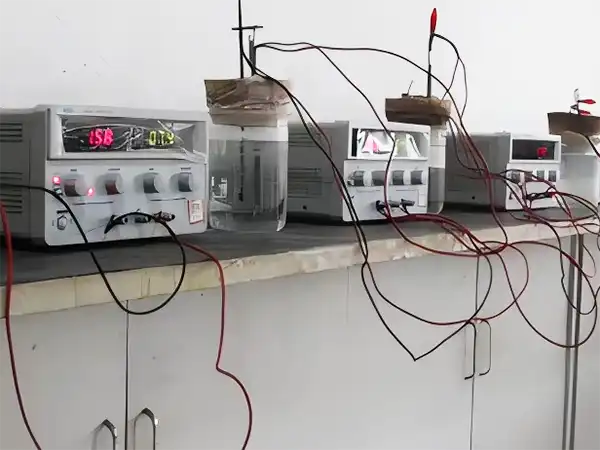

How do you ensure product quality?

Our quality management system includes strict inspections and advanced testing protocols.

-

Do you offer global shipping?

Yes, we deliver to domestic and international markets, ensuring secure and timely shipments.

Contact Details

Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

Experience world-class solutions with our DSA coated titanium anodes today. Contact us for expert guidance and unparalleled service.

YOU MAY LIKE