A titanium anode for seawater desalination is an electrochemical electrode used in electrolytic systems to remove ions, disinfect water, or generate oxidants for cleaning membranes in desalination plants.

The substrate is made of high-purity titanium, typically Grade 1 or Grade 2, due to its excellent corrosion resistance and conductivity. The surface is coated with a mixed metal oxide (MMO) layer—such as IrO₂, RuO₂, or Ta₂O₅—which provides exceptional catalytic activity and stability during chlorine and oxygen evolution reactions.

Technical Specifications of Titanium Anode for Seawater Desalination

|

Parameter |

Specification |

|

Substrate Material |

Titanium (Gr1, Gr2) |

|

Coating Material |

IrO₂–RuO₂–Ta₂O₅ MMO |

|

Coating Thickness |

10–15 µm |

|

Operating Voltage |

3–12 V |

|

Current Density |

100–500 A/m² |

|

Service Life |

10–15 years (depending on usage) |

|

Operating Temperature |

≤ 80°C |

|

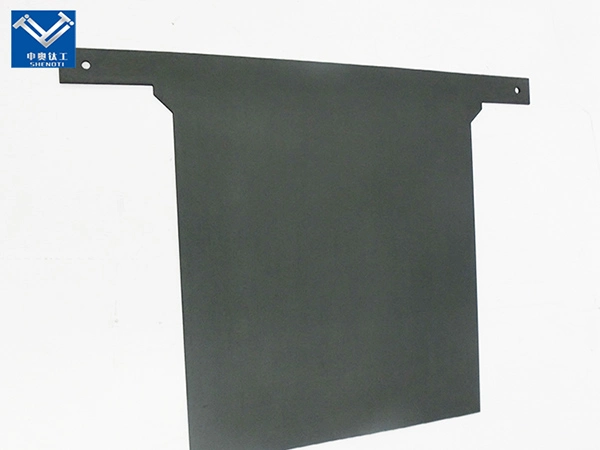

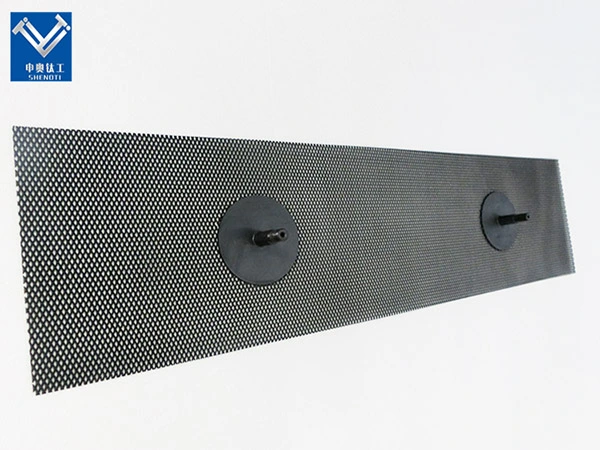

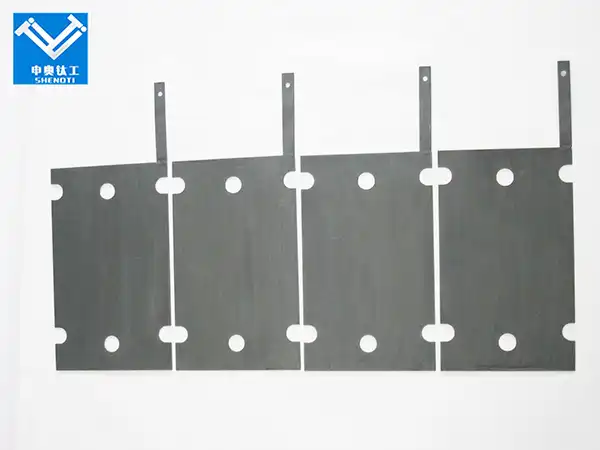

Shape Options |

Plate, Mesh, Tube, Rod, Custom |

How Titanium Anodes Work in Seawater Desalination Systems

Electrochemical Principle

In seawater desalination, titanium anodes are mainly used in electro-chlorination and electrolysis systems. When an electric current passes through seawater, chloride ions are oxidized at the anode to produce chlorine gas, which dissolves to form hypochlorous acid (HOCl) and hypochlorite ions (OCl⁻). These act as powerful disinfectants, preventing biofouling and scaling in reverse osmosis membranes.

Anode Reaction:

2Cl⁻ → Cl₂ + 2e⁻

Cathode Reaction:

2H₂O + 2e⁻ → H₂ + 2OH⁻

This process ensures clean and efficient operation of desalination plants, while also reducing chemical usage and maintenance costs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Using Titanium Anode for Seawater Desalination

1. Outstanding Corrosion Resistance

Titanium anodes are designed to withstand the aggressive chloride ions present in seawater. Unlike graphite or steel electrodes, MMO-coated titanium anodes do not corrode or dissolve, ensuring long-term stability and safety.

2. Energy Efficiency

The low overpotential of titanium anodes minimizes energy consumption, resulting in significant cost savings during continuous operation.

3. Long Service Life

With a robust titanium base and a stable MMO coating, the lifespan of a titanium anode for seawater desalination can exceed 10–15 years, depending on the operating conditions.

4. Eco-Friendly and Low Maintenance

Unlike chemical disinfectants, the electrochemical generation of chlorine using titanium anodes eliminates the need for hazardous chemical storage and transportation. The process is environmentally friendly, safe, and highly controllable.

5. Consistent Performance

Titanium anodes maintain uniform current distribution, which ensures consistent oxidant production and prevents uneven wear or localized corrosion.

Applications of Titanium Anodes in Seawater Desalination and Beyond

1. Reverse Osmosis (RO) Pretreatment

Titanium anodes are widely used in electro-chlorination systems to produce sodium hypochlorite for RO membrane disinfection. This prevents biofilm formation and prolongs membrane life.

2. Electrodialysis Systems

In electrodialysis desalination, titanium anodes enable the efficient transfer of ions across ion-exchange membranes, ensuring optimal conductivity and water purity.

3. Ballast Water Treatment

Titanium anodes generate oxidizing agents to disinfect ballast water, preventing the spread of invasive marine species.

4. Marine and Offshore Applications

From oil platforms to shipboard desalination systems, titanium anodes ensure reliable, maintenance-free operation under extreme saltwater conditions.

5. Wastewater Treatment and Industrial Use

Beyond seawater desalination, titanium anodes are used in chlor-alkali production, electrochemical oxidation of organic pollutants, and industrial disinfection systems.

Titanium Anode Applications in Seawater Desalination Plants Case:

1: Middle East Desalination Facility

A large-scale desalination plant in the UAE adopted titanium anodes for its electro-chlorination system. The use of MMO-coated titanium anodes reduced energy consumption by 20% and extended maintenance intervals from 6 months to over 3 years.

2: Offshore Platform in Southeast Asia

For a marine desalination unit on an offshore oil platform, titanium anodes provided stable chlorine generation under high salinity and temperature conditions, ensuring uninterrupted fresh water supply for operational needs.

3: Coastal Power Plant Cooling Water System

A coastal power plant integrated titanium anode systems to control biofouling in seawater cooling circuits. The system successfully maintained consistent chlorine levels, reducing chemical costs and downtime.

|

|

|

|

|

|

|

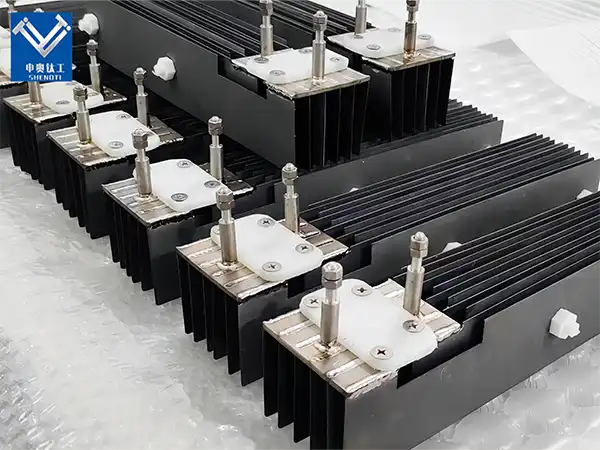

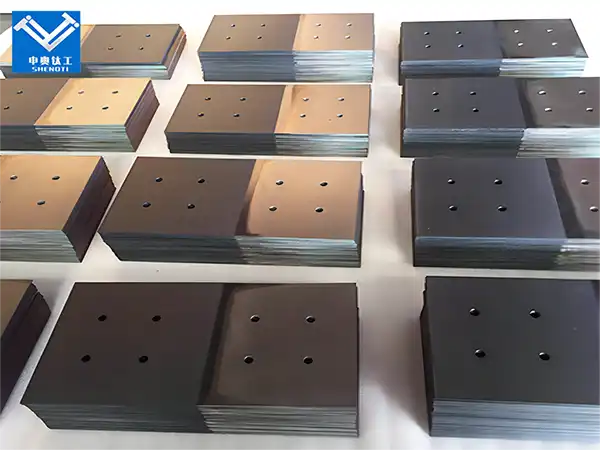

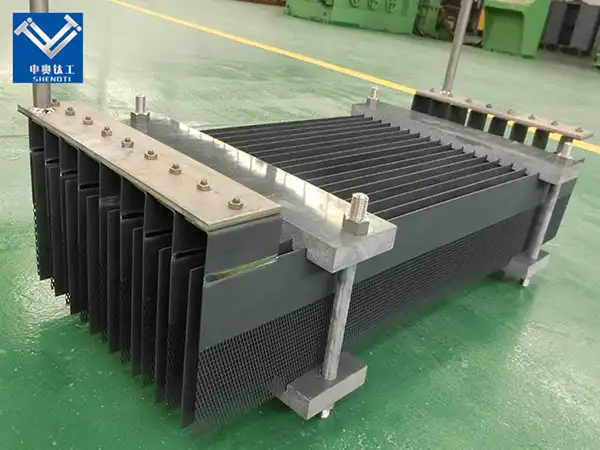

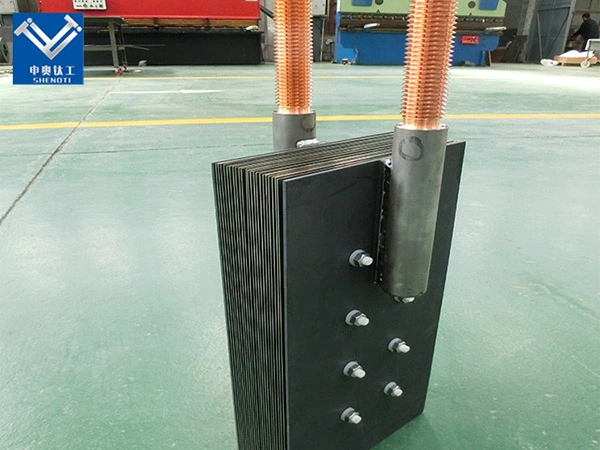

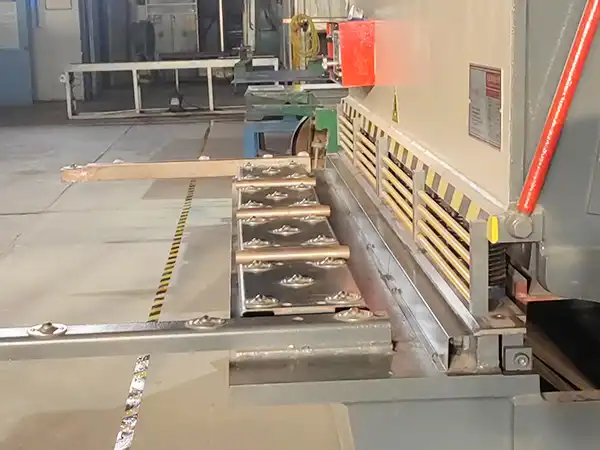

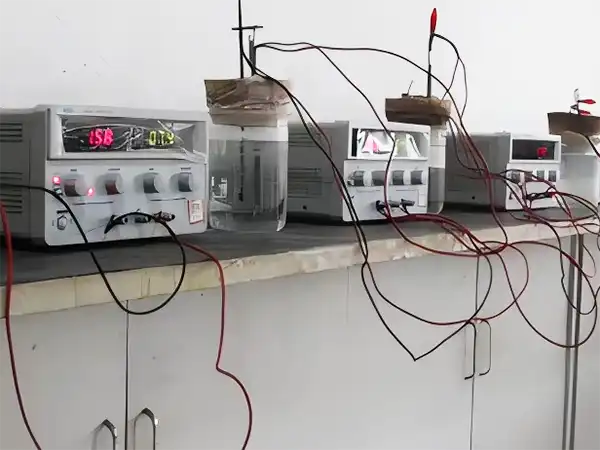

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us as Your Titanium Anode Supplier

As a leading manufacturer in the field of non-ferrous metals and advanced electrode materials, Baoji City ShenAo Metal Materials Co., Ltd. specializes in the design and production of titanium anodes for seawater desalination.

We provide:

-

Customized electrode design according to client specifications

-

Advanced coating technology ensuring high performance and longevity

-

Strict quality control and testing in compliance with international standards

-

Global technical support and after-sales service

Our titanium anodes have been successfully deployed in projects across the Middle East, Southeast Asia, and Europe, proving their superior reliability and efficiency.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: How long does the coating last in seawater desalination systems?

A: The service life typically exceeds five years under standard operating conditions, with minimal maintenance required.

Q2: Can you customize the size and shape of the titanium anode?

A: Yes, we provide fully customizable designs to fit specific project requirements.

Q3: What is the lead time for bulk orders?

A: Lead time varies depending on order size, typically ranging from 2 to 4 weeks.

Q4: Do you offer technical support for installation?

A: Yes, we provide comprehensive technical guidance and after-sales support.

Contact Us

We are here to provide tailored solutions for your seawater desalination needs. Contact us today!

Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

This high-performance Titanium Anode for Seawater Desalination ensures efficient, reliable, and eco-friendly operations. Trust Baoji City ShenAo Metal Materials Co., Ltd. for innovative solutions tailored to your needs. Contact us now to get started!

YOU MAY LIKE

_1735889681337.webp)

_1735889773984.webp)

_1735889823558.webp)

_1735528406026.webp)

_1735529028577.webp)