Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

A titanium anode for electrolytic disinfection in seawater aquaculture is a type of electrochemical electrode designed to generate oxidizing substances—such as chlorine, hypochlorous acid, and oxygen radicals—through the electrolysis of seawater. These oxidants effectively eliminate bacteria, viruses, and algae, providing a safe disinfection method without harmful chemical additives.

Key Functional Principle

During the electrolysis process, the titanium anode serves as the positive electrode. When a current is applied, chloride ions (Cl⁻) present in seawater are oxidized to form chlorine gas, which reacts with water to produce hypochlorous acid (HOCl)—a powerful disinfectant.

The reaction can be simplified as follows:

2Cl⁻ → Cl₂ → HOCl + H⁺ + Cl⁻

This electrolytic reaction ensures continuous disinfection of recirculating seawater in aquaculture tanks, pipelines, and filtration systems.

Technical Parameters and Performance Characteristics

|

Parameter |

Typical Range |

|

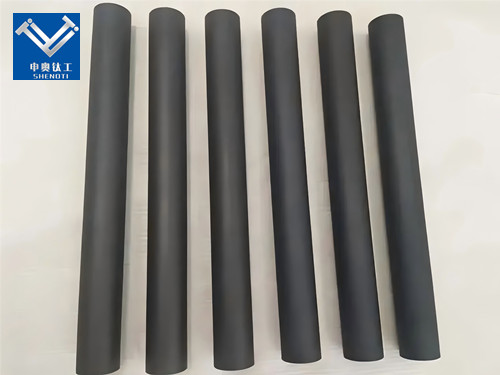

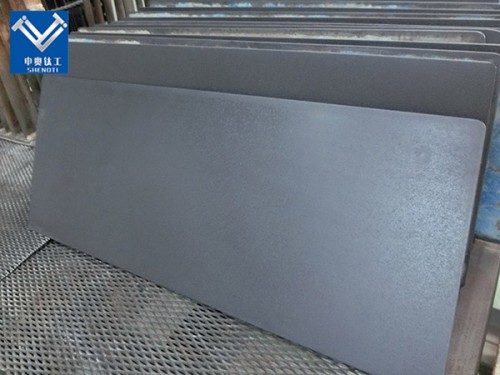

Base Material |

Titanium (Grade 1 / Grade 2) |

|

Coating Composition |

RuO₂–IrO₂, IrO₂–Ta₂O₅, or Pt |

|

Operating Current Density |

100–3000 A/m² |

|

Operating Temperature |

Up to 80°C |

|

Chlorine Evolution Efficiency |

≥ 90% |

|

Expected Service Life |

8000–20000 hours (depending on coating) |

|

Electrolyte |

Seawater / Brackish water |

|

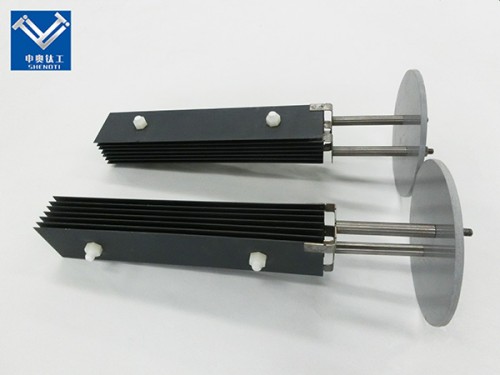

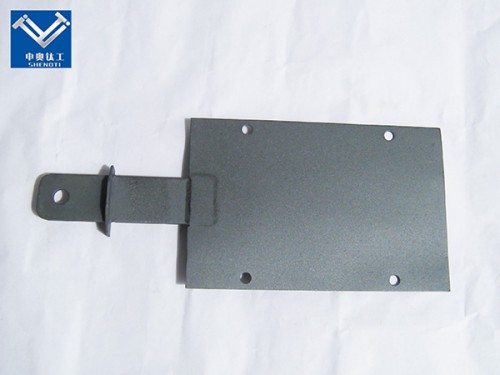

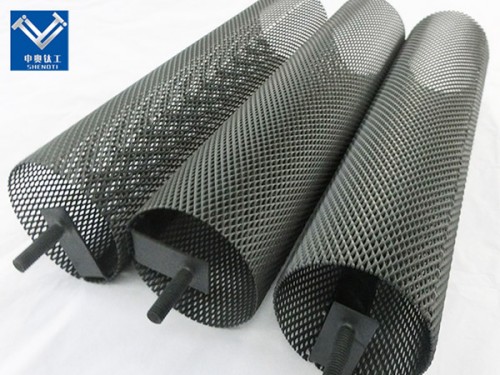

Shape Options |

Plate, mesh, tubular, or custom-designed |

These parameters can be tailored according to specific customer requirements and system configurations.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Using Titanium Anode for Electrolytic Disinfection in Seawater Aquaculture

1. High Disinfection Efficiency

Titanium anodes generate reactive oxidants efficiently, achieving rapid microbial inactivation and stable water quality.

2. Low Energy Consumption

The low chlorine evolution potential of the MMO coating minimizes power use during operation, reducing energy costs for aquaculture farms.

3. Safety and Automation

The system can be fully automated, eliminating the need for manual chemical dosing and improving safety for both operators and marine organisms.

4. Long-Term Cost Savings

While the initial investment may be higher, the long lifespan and low maintenance of titanium anodes lead to significant long-term savings.

Applications of Titanium Anode in Seawater Aquaculture

1. Fish and Shrimp Hatcheries

In aquaculture hatcheries, maintaining sterile conditions is vital for larval survival. Titanium anodes effectively disinfect intake seawater and recirculating systems, preventing the spread of pathogenic microorganisms such as Vibrio and Aeromonas.

2. Recirculating Aquaculture Systems (RAS)

Modern RAS facilities rely on continuous water reuse. The titanium anode for electrolytic disinfection in seawater aquaculture minimizes biofouling in pipelines and filtration units, ensuring stable water quality and reducing maintenance frequency.

3. Seawater Intake and Cooling Systems

In coastal aquaculture plants, seawater intake channels often suffer from biofilm and algae buildup. Installing titanium anodes in these systems provides continuous and automatic disinfection, extending equipment lifespan and improving operational efficiency.

4. Offshore Fish Farming Cages

For open-sea aquaculture cages, electrolytic disinfection systems powered by titanium anodes can help maintain water purity around cages and prevent disease outbreaks caused by bacterial blooms.

Real-World Case Studies

1: Seawater Shrimp Hatchery in Southeast Asia

A coastal shrimp hatchery implemented a titanium anode electrolytic disinfection system to treat intake seawater. The bacterial count decreased by 98%, resulting in a 20% increase in larval survival rate and a noticeable improvement in water clarity.

2: Offshore Fish Farming in Norway

In an offshore salmon farm, titanium anodes were used in a recirculating disinfection system to control algae growth. After six months, the system maintained consistent performance without electrode replacement, proving the durability of the MMO-coated titanium.

3: Seawater Cooling System in China

An industrial aquaculture plant integrated titanium anodes into its cooling and water supply lines. The electrolytic process prevented biofilm formation, reducing maintenance downtime by 40%.

|

|

|

|

|

|

|

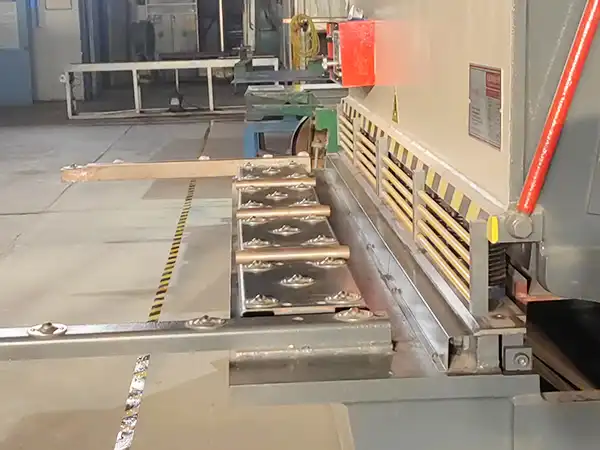

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

-

Research and Innovation

With 17 years of experience, we continuously innovate to meet the dynamic needs of the aquaculture and marine industries. -

Proven Reputation

Trusted by global clients for quality and reliability, Baoji City ShenAo Metal Materials Co., Ltd. has established itself as a leader in titanium anode manufacturing. -

Commitment to Excellence

Stringent production standards and quality control ensure every anode meets or exceeds industry expectations. -

Custom Solutions

Whether you need standard models or unique designs, we offer tailored solutions to meet your specific requirements. -

Timely Delivery and Support

From quick order fulfillment to comprehensive after-sales service, we prioritize customer satisfaction. -

OEM Services

Partner with us to produce titanium anodes under your brand, expanding your market reach with confidence.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. How long do titanium anodes last in seawater?

Our anodes are designed to last over five years, depending on operational conditions and maintenance.

2. Can I customize the size and shape of the anode?

Yes, we provide custom designs to suit your specific application.

3. Are these anodes environmentally friendly?

Absolutely! They eliminate the need for chemical disinfectants, promoting sustainable and eco-friendly practices.

4. Do you provide technical support for installation?

Yes, our team offers comprehensive guidance and support for seamless integration into your systems.

5. What certifications do your products have?

All our products comply with ISO 9001, CE, and RoHS standards, ensuring top-tier quality and safety.

Contact Us

For inquiries or orders, please get in touch with us:

Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact Person: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

We are dedicated to providing professional services and tailored solutions to meet your needs.

This page highlights the key advantages of our Titanium anode for electrolytic disinfection in seawater aquacultures, addressing customer pain points and aligning with SEO best practices to boost visibility and engagement.

YOU MAY LIKE