Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

Titanium anodes for wastewater treatment are electrochemical electrodes made primarily from high-purity titanium substrates coated with active catalytic materials such as ruthenium oxide (RuO₂), iridium oxide (IrO₂), or mixed metal oxides (MMO). These coatings enhance the electrode’s conductivity, corrosion resistance, and catalytic activity, making titanium anodes a cornerstone in modern wastewater purification systems.

In wastewater treatment, titanium anodes act as the driving force behind electrochemical oxidation processes that break down organic pollutants, oxidize heavy metals, and disinfect harmful microorganisms. Their durability, efficiency, and eco-friendly operation make them an indispensable part of industrial and municipal water treatment facilities worldwide.

Technical Specifications

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

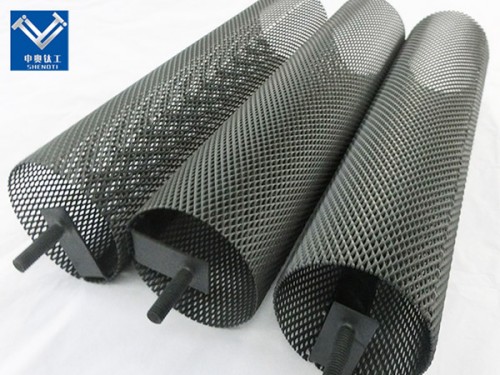

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical Advantages of Titanium Anodes for Wastewater Treatment

1. Long Service Life

Titanium anodes can last up to 10–15 years under normal operating conditions, significantly reducing maintenance costs and downtime.

2. High Current Efficiency

The advanced catalytic coating ensures efficient electron transfer, resulting in lower energy consumption and higher oxidation rates.

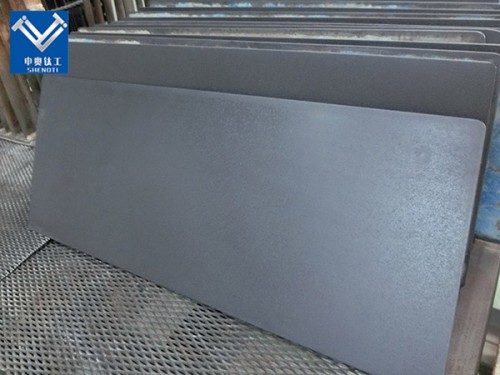

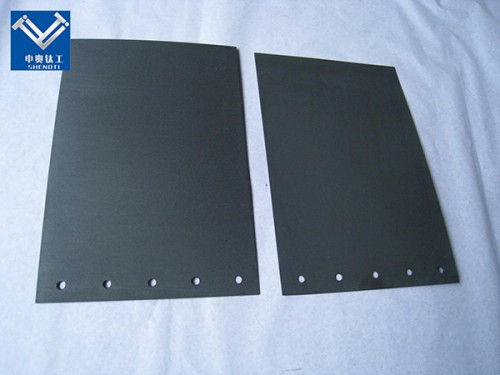

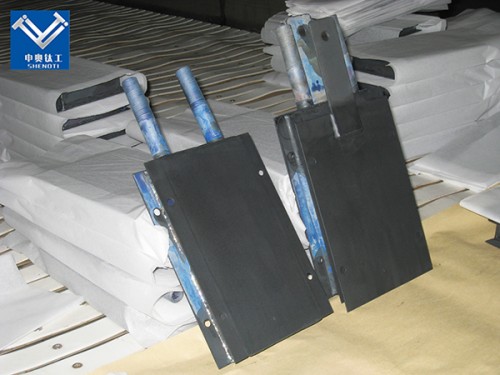

3. Adjustable Structure and Custom Design

Titanium anodes can be fabricated in various shapes—plate, mesh, tube, or rod—to match different reactor designs and operating conditions.

4. Wide Operating Range

They perform reliably across a broad pH range (1–12) and temperature conditions, offering great flexibility for industrial applications.

Applications of Titanium Anodes for Wastewater Treatment

1. Industrial Wastewater Treatment

Titanium anodes are used extensively in industries such as:

Electroplating (removal of cyanides, chromium, and nickel ions)

Petrochemical (degradation of hydrocarbons and phenols)

Textile (oxidation of dyes and surfactants)

Pharmaceutical (elimination of refractory organic compounds)

By utilizing electrochemical oxidation, titanium anodes decompose complex organic molecules into simpler, harmless compounds like CO₂ and H₂O.

2. Municipal Wastewater Treatment

Municipal facilities use titanium anodes for disinfecting sewage and reducing biological oxygen demand (BOD) and chemical oxygen demand (COD) levels. This results in cleaner, safer water suitable for discharge or reuse.

3. Landfill Leachate Treatment

Titanium anodes for wastewater treatment are also highly effective in breaking down ammonia nitrogen and organic pollutants found in landfill leachate, which is known for its high toxicity and complex composition.

4. Reuse and Recycling Applications

In water recycling systems, titanium anodes assist in advanced oxidation processes to regenerate treated water for industrial reuse—promoting sustainability and resource conservation.

Successful Applications of Titanium Anodes Case:

1: Electroplating Wastewater Treatment

A large electroplating facility adopted MMO-coated titanium anodes to treat wastewater containing hexavalent chromium and heavy metals. The electrochemical oxidation process achieved over 95% chromium removal while reducing COD by 80%. The system has operated continuously for more than 8 years with minimal maintenance.

2: Pharmaceutical Industry

A pharmaceutical company used titanium anodes to decompose antibiotic residues in wastewater. The treatment reduced persistent organic pollutants and met stringent environmental discharge standards without chemical additives.

3: Landfill Leachate Treatment

In a municipal landfill project, titanium anodes were used for electrochemical oxidation of leachate containing ammonia nitrogen and phenolic compounds. The process improved biodegradability, allowing integration with biological treatment systems for complete purification.

|

|

|

|

|

|

|

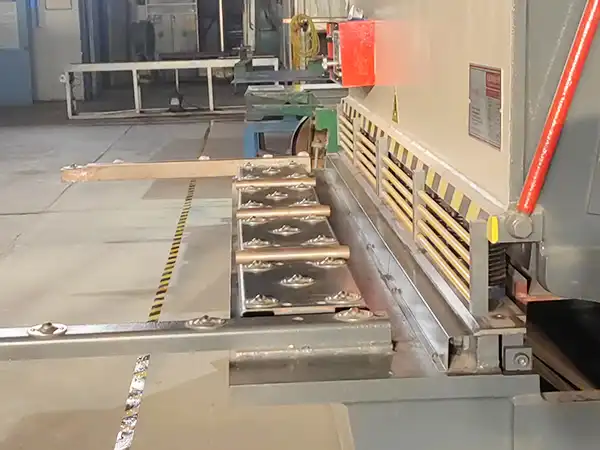

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

1. Research and Innovation

With over 17 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. leads the market in developing advanced titanium anode solutions. Our dedicated R&D team ensures innovative designs and superior Titanium anodes for wastewater treatment performance.

2. Excellent Reputation

Recognized for reliable quality and customer service, we are a trusted partner for industries worldwide.

3. Striving for Excellence

Our robust quality management system guarantees that every product meets industry standards, whether for small batch testing or large-scale production.

4. Customized Product Services

We provide tailored solutions to meet the unique requirements of different wastewater treatment systems, ensuring maximum efficiency and performance.

5. Timely Delivery and Support

We prioritize customer satisfaction with on-time delivery and comprehensive after-sales support.

6. OEM Services

We offer OEM production to align with your branding and specifications.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is the lifespan of your titanium anodes?

Our anodes typically last 8-10 years under standard operating conditions, depending on the coating type and application.

Q2: Are your titanium anodes customizable?

Yes, we provide fully customizable anodes to meet your specific wastewater treatment needs.

Q3: How do you ensure product quality?

We follow a strict quality management system and conduct thorough testing at every production stage.

Q4: Can you provide technical support?

Absolutely! Our team offers comprehensive guidance on installation, operation, and maintenance.

Contact Us

For inquiries or to place an order, reach out to us:

Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

We are here to provide professional, timely service for all your titanium anode requirements.

This optimized product page is designed to boost engagement and ensure top rankings for the keyword "Titanium anodes for wastewater treatment", driving valuable traffic to your business.

YOU MAY LIKE