Superior conductivity for efficient electrochemical reactions.

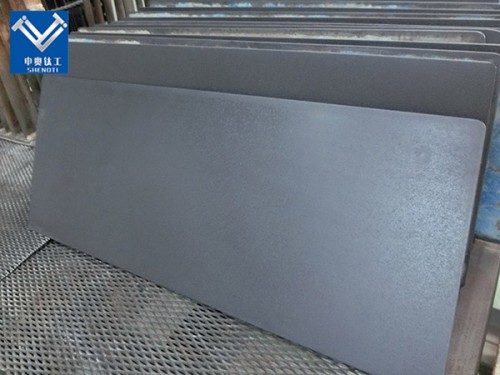

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

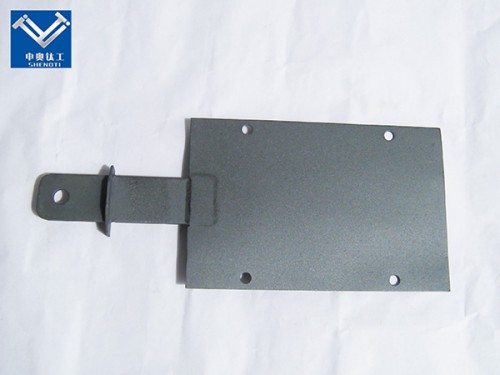

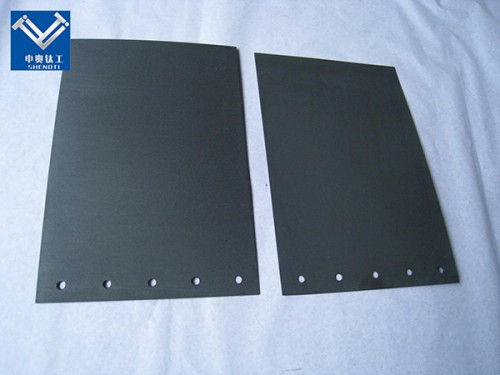

Customizable sizes for various industrial applications.

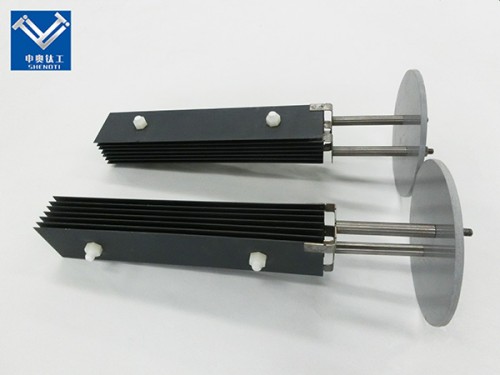

Titanium Anodes for Industrial Wastewater Treatments Introduction

Industrial wastewater treatment is a critical process that demands reliable and high-performance solutions. At Baoji City ShenAo Metal Materials Co., Ltd., our Titanium anodes for industrial wastewater treatments are engineered to deliver superior corrosion resistance, efficiency, and longevity. Designed for applications in harsh environments, these anodes ensure optimal performance while supporting sustainable and eco-friendly industrial operations.Our titanium anodes utilize advanced coating technology, making them ideal for a variety of wastewater treatment systems, including electrochemical oxidation, electrocoagulation, and electrolysis.

With extensive applications across industries such as petrochemicals, textiles, and pharmaceuticals, our titanium anodes offer unmatched reliability and innovation. These anodes are specifically designed to handle the complex chemistry of wastewater, providing a robust solution that ensures efficient contaminant removal and minimized environmental impact。

Technical Specifications and Customization Options

|

Parameter |

Description |

|

Base Material |

Pure Titanium (Gr1, Gr2) |

|

Coating Type |

RuO₂-IrO₂, IrO₂-Ta₂O₅, MMO |

|

Form |

Plate, Mesh, Rod, Tube |

|

Current Density |

100–5000 A/m² |

|

Operating Voltage |

2–12 V |

|

Service Life |

>10,000 hours (depending on medium) |

|

pH Range |

0–14 |

|

Temperature Range |

Up to 80°C |

|

Applications |

Electro-oxidation, metal ion removal, chlor-alkali systems, advanced oxidation |

Custom sizes, coatings, and configurations are available to meet diverse application requirements. Each anode can be tailored according to electrochemical cell design, current density, and wastewater composition.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Choosing Titanium Anodes for Industrial Wastewater Treatments

1. High Electrochemical Efficiency

Titanium anodes enable uniform current distribution and superior pollutant degradation efficiency.

2. Energy Savings

With lower overpotential, titanium anodes reduce energy consumption during electrolysis, lowering operational costs.

3. Stable Operation

Excellent coating adhesion and mechanical strength ensure consistent performance even in harsh chemical environments.

4. Eco-Friendly Performance

No secondary pollution, recyclable materials, and compliance with international RoHS and REACH standards.

5. Custom Engineering Support

Manufacturers like Baoji City ShenAo Metal Materials Co., Ltd. provide custom design, prototype development, and after-sales support tailored to industrial client needs.

Applications of Titanium Anodes in Industrial Wastewater Treatments

1. Electrochemical Oxidation

In electrochemical oxidation systems, titanium anodes serve as catalysts for degrading organic pollutants like phenols, dyes, and surfactants. The process converts complex compounds into CO₂ and H₂O without generating secondary pollution.

2. Heavy Metal Removal

Titanium anodes efficiently precipitate and separate heavy metals such as copper, nickel, chromium, and zinc from wastewater, achieving high purification rates suitable for electroplating and metallurgical industries.

3. Cyanide and Ammonia Decomposition

Many industrial effluents contain toxic cyanides or ammonia. Titanium anodes, especially those with mixed metal oxide coatings, accelerate oxidation to produce non-toxic nitrates and carbonates, ensuring safe discharge.

4. Electro-Fenton and Advanced Oxidation Processes (AOPs)

In electro-Fenton systems, titanium anodes generate hydroxyl radicals (•OH), powerful oxidants that mineralize persistent organic compounds. These methods are widely adopted in pharmaceutical, chemical, and textile wastewater treatment.

5. Recycling and Water Reuse Systems

Industries adopting zero liquid discharge (ZLD) technologies increasingly rely on titanium anodes for water recycling and resource recovery, supporting sustainable manufacturing.

Titanium Anodes for Industrial Wastewater Treatments Proven Performance in Industrial Applications Case:

1: Electroplating Wastewater Treatment in Southeast Asia

A large electroplating facility adopted RuO₂-IrO₂ coated titanium anodes, achieving over 98% reduction of heavy metal ions and organic pollutants. The service life exceeded 3 years with minimal maintenance.

2: Textile Dyeing Wastewater Oxidation in Europe

Using MMO titanium mesh anodes, a textile plant reduced COD (Chemical Oxygen Demand) by 95%, ensuring compliance with EU discharge standards.

3: Chemical Plant Effluent Treatment in China

Baoji ShenAo’s IrO₂-Ta₂O₅ titanium anodes were installed in a chlorinated wastewater oxidation system, operating stably for over 10,000 hours with consistent removal efficiency.

|

|

|

|

|

|

|

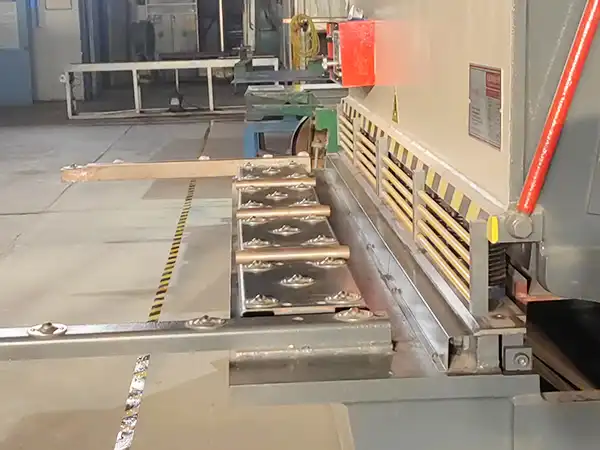

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

-

Research and Innovation

With a dedicated R&D team, we continuously explore advanced technologies to improve Titanium anodes for industrial wastewater treatme performance and cater to diverse applications. -

Excellent Reputation

With over 17 years of industry experience, we are trusted by customers globally for our superior quality and customer-centric approach. -

Customized Product Services

We specialize in designing anodes tailored to specific technical requirements, ensuring compatibility with your systems. -

Timely Delivery and Support

Our efficient production and logistics ensure that your orders arrive on time, with robust after-sales support for a hassle-free experience. -

Sustainability Focus

Our products not only meet industrial needs but also align with global efforts for environmental preservation.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

OEM Services

We provide OEM services for businesses looking to customize Titanium anodes for industrial wastewater treatments under their own brand. From design to production, our team ensures seamless execution tailored to your market needs.

FAQs

-

What is the expected lifespan of titanium anodes?

The service life varies depending on the operating conditions but typically ranges from 5 to 10 years. -

Can the anodes be used in extreme pH conditions?

Yes, our anodes are designed to operate effectively across a wide pH range (0–14). -

Do you offer bulk discounts for large orders?

Yes, we provide competitive pricing for bulk orders. Contact us for a customized quote. -

What is the delivery timeline for customized anodes?

Customized orders typically ship within 2–4 weeks, depending on the complexity of the specifications.

Contact Us

For inquiries and customized solutions, reach out to us:

Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Let us help you revolutionize wastewater treatment with advanced Titanium anodes for industrial wastewater treatme solutions.

YOU MAY LIKE