Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

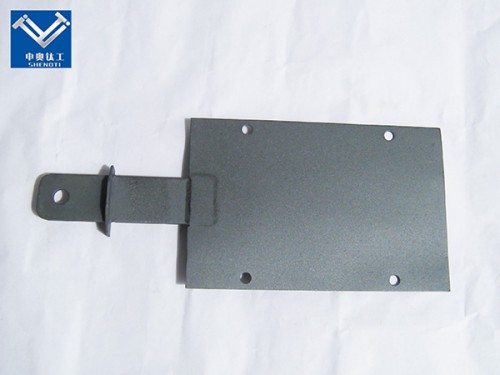

Customizable sizes for various industrial applications.

In the modern era of industrial expansion and urbanization, wastewater pollution has become one of the most pressing environmental challenges. As industries strive to meet stricter environmental regulations, titanium anode for electrolytic sewage treatment has emerged as an efficient and sustainable solution. Its superior corrosion resistance, high electrochemical performance, and long service life make it the preferred electrode material in advanced wastewater treatment systems worldwide.

What is a Titanium Anode for Electrolytic Sewage Treatment?

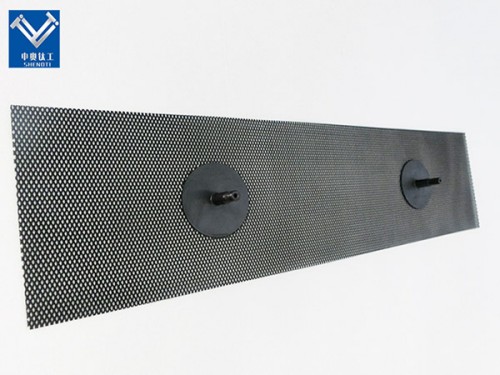

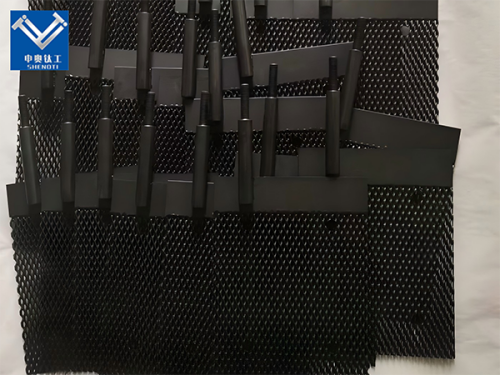

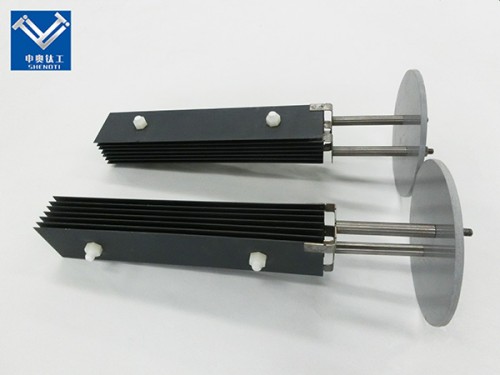

A titanium anode for electrolytic sewage treatment is a specialized electrochemical electrode designed for the oxidation and decomposition of organic and inorganic pollutants in wastewater. These anodes are made of pure titanium substrate coated with catalytic precious metal oxides such as ruthenium oxide (RuO₂), iridium oxide (IrO₂), or platinum (Pt).

When current passes through the anode during the electrolysis process, strong oxidizing agents (like hydroxyl radicals and active chlorine) are generated. These agents efficiently degrade pollutants, achieving decolorization, deodorization, and sterilization of the wastewater without secondary pollution.

In essence, the titanium anode acts as the core component that determines the efficiency, stability, and lifespan of an electrolytic sewage treatment system.

Technical Parameters of Titanium Anode for Electrolytic Sewage Treatment

|

Parameter |

Typical Specification |

|

Substrate Material |

Titanium (Grade 1 or 2) |

|

Coating Composition |

RuO₂ + IrO₂ + TiO₂ or Pt |

|

Coating Thickness |

5–15 µm |

|

Current Density |

10–500 A/m² |

|

Operating Temperature |

≤ 80°C |

|

Service Life |

5–10 years |

|

Shape Options |

Plate, mesh, tube, or custom design |

|

Application Field |

Industrial wastewater, municipal sewage, chemical effluent |

These parameters can be customized according to the type of wastewater and required oxidation intensity, ensuring optimal performance for each electrolytic sewage treatment project.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key Advantages of Titanium Anode in Electrolytic Sewage Treatment

1. Excellent Corrosion Resistance

Titanium is naturally resistant to corrosion, even in highly acidic or alkaline environments. The oxide coating further enhances this property, allowing the titanium anode for electrolytic sewage treatment to perform reliably in harsh industrial effluents that contain chloride, sulfate, and heavy metals.

2. High Electrochemical Efficiency

The catalytic coating of RuO₂–IrO₂ or Pt significantly reduces energy consumption by lowering the oxygen evolution potential. This ensures that more electrical energy is used to produce oxidizing species instead of being wasted. As a result, titanium anodes deliver higher current efficiency and shorter treatment times.

3. Long Service Life

A well-manufactured titanium anode can operate for 5 to 10 years depending on current density and wastewater composition. Its stable coating adheres firmly to the titanium substrate, minimizing peeling or degradation during long-term operation.

4. Environmental and Economic Benefits

Unlike consumable graphite or lead electrodes, titanium anodes are non-polluting and recyclable. Their long lifespan reduces replacement costs and downtime, making them the most cost-effective solution for continuous industrial wastewater treatment.

Applications of Titanium Anode in Wastewater Treatment Industries

The versatility of the titanium anode for electrolytic sewage treatment makes it suitable for multiple industries, including:

1. Chemical and Petrochemical Wastewater

In chemical and petrochemical plants, effluents often contain high concentrations of organic compounds, oil, and phenols. Titanium anodes effectively decompose these pollutants through strong oxidation, ensuring compliance with discharge standards.

2. Electroplating and Metal Finishing

Electroplating wastewater contains heavy metals like Cu²⁺, Ni²⁺, and Cr⁶⁺. The titanium anode facilitates oxidation and precipitation of these ions, preventing heavy metal contamination.

3. Pharmaceutical and Textile Industries

These sectors generate colored and toxic wastewater. Titanium anodes degrade complex dyes, surfactants, and pharmaceutical residues, achieving color removal and biodegradability improvement.

4. Municipal Sewage Treatment

In municipal wastewater treatment plants, titanium anodes are integrated into electrochemical advanced oxidation processes (EAOPs) to enhance biological treatment efficiency and disinfect treated water.

5. Recycling and Zero-Discharge Systems

Titanium anodes are also used in closed-loop water recycling systems, where their durability supports continuous operation with minimal maintenance.

Titanium Anode in Electrolytic Sewage Treatment Plant Case :

A real-world application illustrates the benefits of using titanium anodes in electrolytic wastewater treatment.

Project Background:

A metal surface treatment factory in Southeast Asia faced challenges in treating its high-COD electroplating wastewater. The company implemented an electrolytic oxidation system equipped with RuO₂–IrO₂ titanium anodes.

Results:

COD removal rate exceeded 90% within 3 hours.

Ammonia nitrogen decreased by 85%.

System operated continuously for 18 months with no significant anode degradation.

Power consumption reduced by 20% compared to traditional graphite electrodes.

This case demonstrates the superior durability, efficiency, and environmental performance of titanium anodes in practical industrial sewage treatment applications.

|

|

|

|

|

|

|

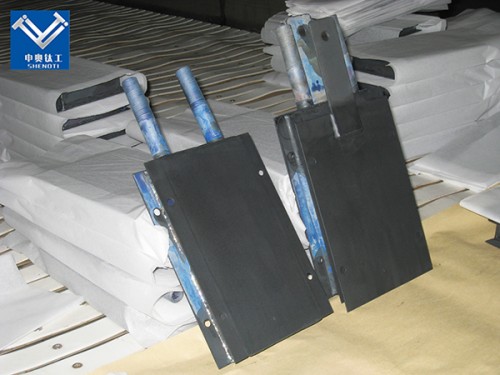

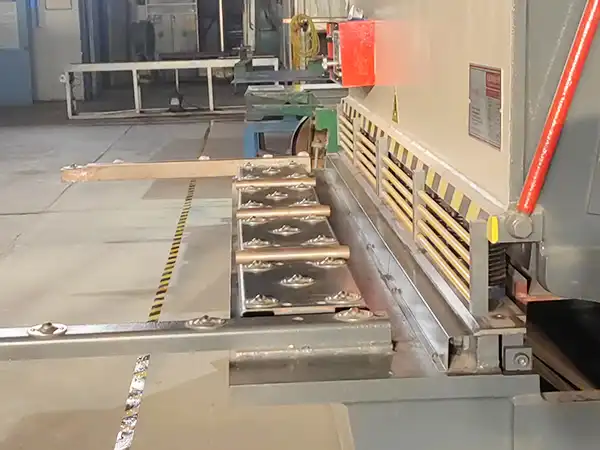

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Titanium Anodes from Baoji ShenAo Metal Materials Co., Ltd.?

Baoji ShenAo Metal Materials Co., Ltd., located in China’s titanium valley — Baoji City, specializes in the production of titanium anodes for electrolytic sewage treatment, as well as a wide range of titanium-based and precious metal electrodes.

1: Our Advantages

Over 15 years of manufacturing experience in titanium and non-ferrous metal materials.

Advanced vacuum coating and thermal oxidation equipment.

Strict ISO 9001 quality management system.

Custom solutions for different wastewater compositions and industrial environments.

Exported to Europe, North America, and Southeast Asia, earning a strong international reputation.

2: Product Range

Titanium anode for wastewater treatment

DSA (Dimensionally Stable Anode) electrodes

MMO (Mixed Metal Oxide) anodes

Platinum-plated titanium anodes

Titanium cathodes and custom electrode assemblies

Our commitment is to provide high-performance anode solutions that help global industries achieve environmental compliance, energy efficiency, and sustainable production.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

OEM service

We pride ourselves on offering highly flexible Original Equipment Manufacturer (OEM) services, which encompass the provision of titanium anodes specifically designed for titanium anode for electrolytic sewage treatment. These anodes can be customized to meet your exact dimensions, coatings, and specifications, ensuring that they seamlessly integrate into your unique industrial setup. By collaborating with us, you can leverage our expertise to develop tailored solutions that cater precisely to the demands of your industrial processes. Together, we can create a customized product that maximizes efficiency and performance in your electrolytic sewage treatment operations.

FAQs

Q: What is the expected lifespan of the titanium anode?

A: The titanium anode for electrolytic sewage treatment typically lasts over 5 years under standard operating conditions.

Q: Can the anode be used in extreme pH environments?

A: Yes, it operates effectively across a pH range of 0–14.

Q: Do you provide technical support for installation?

A: Absolutely! Our team offers guidance and on-site support as needed.

Contact Us

Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

Partner with us for innovative, efficient, and sustainable titanium anode for electrolytic sewage treatment solutions!

YOU MAY LIKE