Because they function as the cathode in electrolysis and offer excellent efficiency and long-lasting performance, titanium anode is crucial parts of electrochemical processes. To increase their longevity and resistance to corrosion, these anodes are made from premium titanium and coated with active substances like ruthenium or iridium. Numerous industries, such as chemical production, wastewater treatment, electrowinning, and seawater desalination, use the products. They support environmental sustainability, equipment longevity, and energy consumption reduction.

Technical Specifications

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

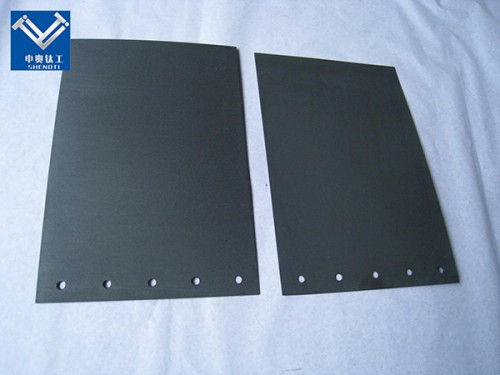

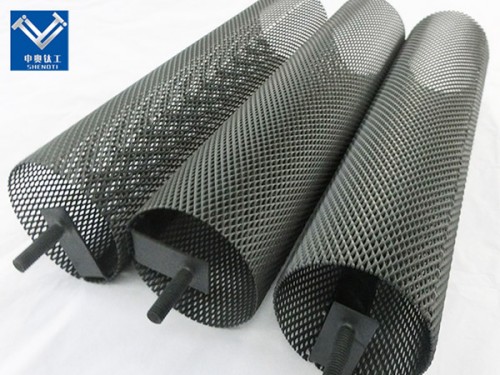

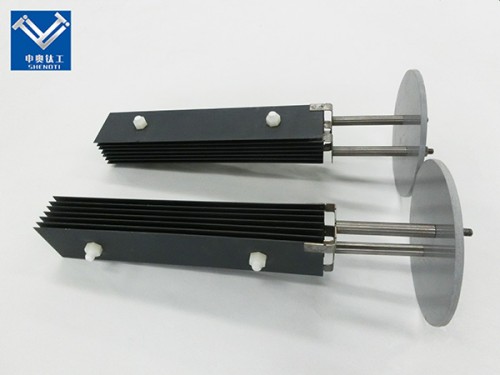

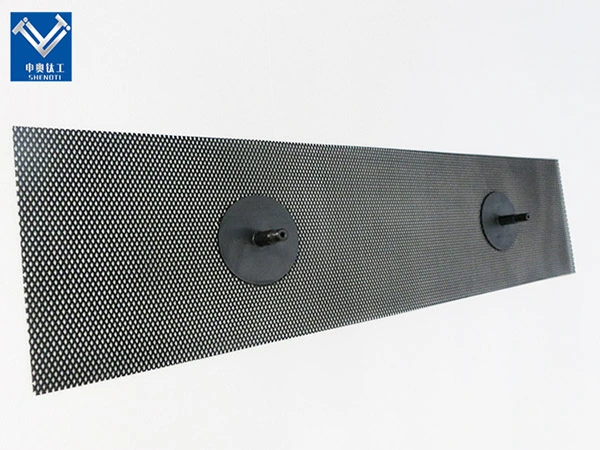

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

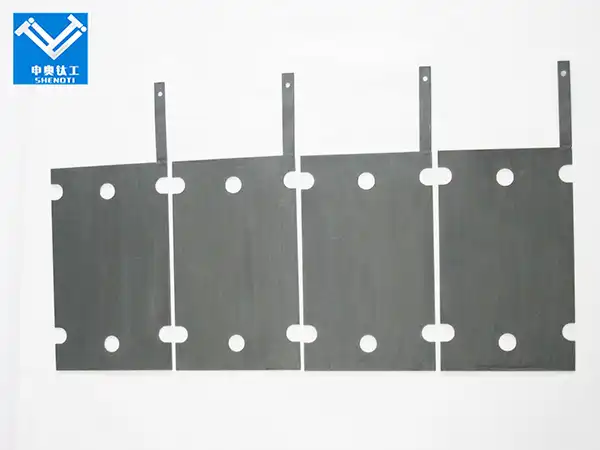

Manufacturing Process of Titanium Anode

The performance of a titanium anode largely depends on the quality of its substrate and coating. The manufacturing process involves several critical steps to ensure durability and electrochemical efficiency.

1: Titanium Substrate Preparation

High-purity titanium sheets, plates, or rods are selected as the base material. The substrate is cleaned, polished, and treated to remove impurities and enhance surface roughness. This ensures strong adhesion between the titanium surface and the coating.

2: Coating Application

The titanium substrate is coated with a thin layer of catalytic material, usually precious metal oxides such as RuO₂, IrO₂, or a combination of MMO coatings. The coating is applied through techniques like thermal decomposition, brush coating, or spray coating. Multiple layers are applied for maximum durability.

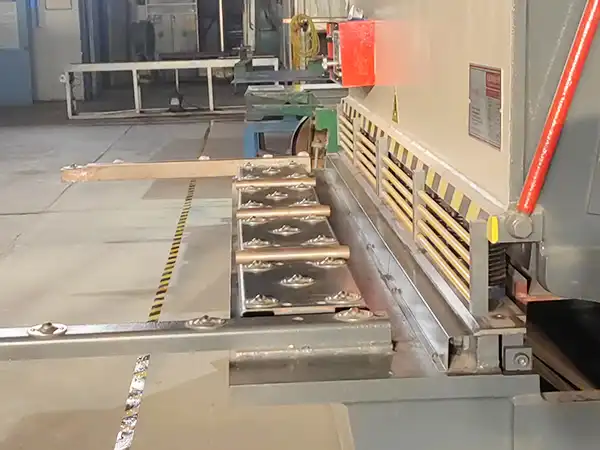

3: Heat Treatment

The coated substrate is subjected to controlled heat treatment, which activates the catalytic layer and ensures strong bonding with the titanium base. This step is crucial for enhancing the anode’s electrochemical stability and conductivity.

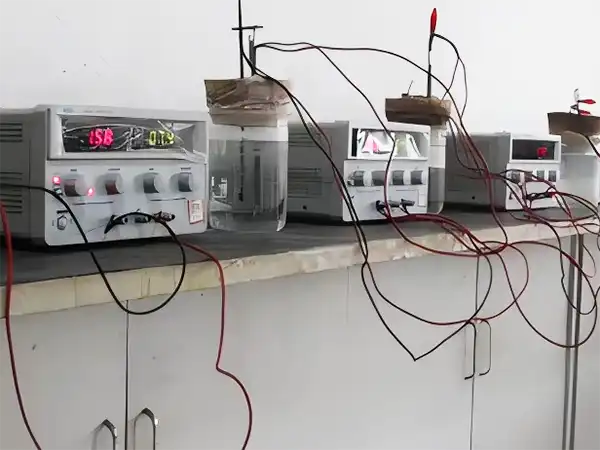

4: Quality Testing

Each titanium anode undergoes strict quality control testing, including adhesion testing, electrochemical performance evaluation, and dimensional inspection. Only anodes meeting international standards are approved for industrial use.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Titanium Anode Advantages

- Corrosion Resistance:Our products offer exceptional resistance to corrosion, even in harsh environments such as seawater and industrial chemicals. The coating materials further enhance this property, ensuring longevity and reliability.

- Energy Efficiency: The use of titanium anodes significantly reduces energy consumption in electrochemical processes, making them an eco-friendly choice.

- Customization: Our products can be tailored to meet specific requirements, including coating material, dimensions, and electrode surface area, ensuring optimal performance for each application.

- High Performance: Titanium’s excellent conductivity and the anodes’ high current density ensure efficient operation, making them suitable for high-demand processes.

- Durability: Thanks to the robust nature of titanium and its specialized coatings, Our products have a long service life, reducing the need for frequent replacements.

Applications of Titanium Anode

Titanium anodes are widely used across multiple industries due to their durability and versatility.

1. Electroplating Industry

Titanium anodes are critical in the electroplating process, where they provide uniform current distribution and long-term stability. They are especially effective for plating precious metals such as gold, silver, platinum, and rhodium.

2. Water Treatment

In wastewater treatment and swimming pool disinfection, titanium anodes are used for electrochlorination and advanced oxidation processes. Their ability to generate active chlorine and hydroxyl radicals makes them highly effective for removing organic contaminants.

3.Chlor-Alkali Industry

Titanium anodes coated with ruthenium and iridium oxides are essential in the chlor-alkali process, producing chlorine gas and sodium hydroxide through electrolysis of brine.

4. Cathodic Protection

In marine structures, pipelines, and storage tanks, titanium anodes provide cathodic protection by preventing corrosion of steel and other metals exposed to seawater or soil.

5. Metal Refining and Electrowinning

Titanium anodes are used in hydrometallurgy for extracting non-ferrous metals like copper, zinc, and nickel through electrowinning processes.

6. Other Applications

Electrolytic production of persulfates

Anodizing aluminum

Organic synthesis and chemical processing

Titanium Anode Applications Application Case

1: Wastewater Treatment Plant

A municipal wastewater treatment facility replaced lead-based anodes with titanium anodes coated with mixed metal oxides. The result was a 30% reduction in power consumption and improved pollutant degradation efficiency.

2: Offshore Cathodic Protection

An offshore oil platform installed titanium anodes for cathodic protection of steel structures. The anodes provided a service life of more than 20 years, reducing maintenance costs and downtime.

3: Gold Electroplating

A jewelry manufacturer adopted titanium anodes for gold plating operations. The company achieved uniform coating thickness, reduced energy costs, and extended anode life, enhancing overall production efficiency.

|

|

|

|

|

|

|

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us: Our Advantages

-

Research and Innovation

Baoji City ShenAo Metal Materials Co., Ltd. has a dedicated technical research and development team, continuously exploring new applications and improving our products to meet the evolving needs of our customers. Our focus on innovation ensures we provide cutting-edge solutions that maximize performance and efficiency. -

Excellent Reputation

With over 17 years in the industry, we have built a strong reputation for delivering high-quality titanium anode and metal materials. Our commitment to customer satisfaction has earned us the trust of clients worldwide. -

Striving for Excellence

We adhere to strict production standards and quality control processes to ensure each product meets our high-quality benchmarks. Our stable production practices ensure timely deliveries and consistent product quality. -

Customized Product Services

We understand that each application may have unique requirements. That’s why we offer tailored solutions, including customized specifications and coatings, to meet the specific needs of our clients. -

Timely Delivery & Worry-Free After-Sales Service

Our efficient logistics ensure that products are delivered on time. We also provide excellent after-sales support, addressing any concerns and ensuring optimal product performance. -

OEM Services

We offer OEM services to meet the diverse needs of our international clients, providing custom branding and packaging options.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

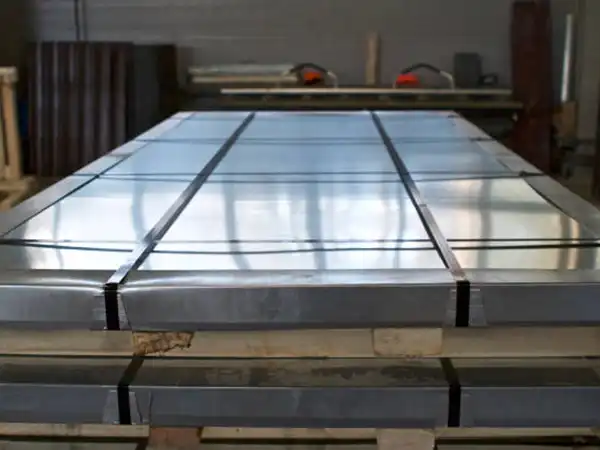

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

-

What makes titanium anodes better than other materials?

Our products offer superior corrosion resistance, especially in harsh environments such as seawater and industrial chemicals. They also have longer lifespans and higher efficiency in electrochemical applications compared to other materials. -

How long do the products last?

Depending on the application and environmental conditions,Our products can last between 10-15 years, making them a cost-effective and durable solution. -

Can I get custom-sized products?

Yes, we provide titanium anode in custom sizes, coatings, and dimensions to meet the specific needs of your project.

Contact Details

For more information or to place an order, please feel free to contact us:

Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

E-MAIL: zh@baojiti.com.cn

YOU MAY LIKE