Titanium Anode for Sodium Hypochlorite Generator

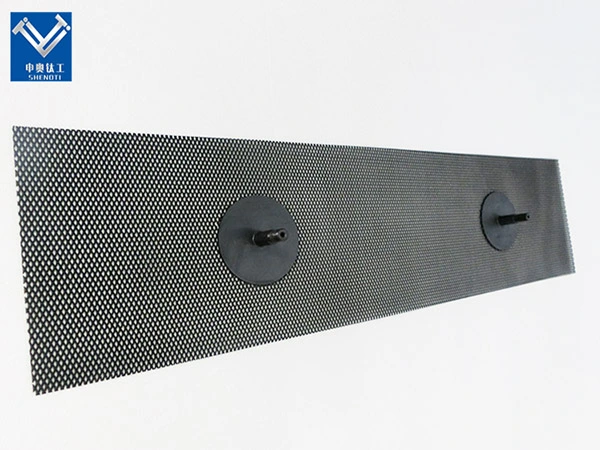

A titanium anode for sodium hypochlorite generator is an electrochemical electrode made from high-purity titanium substrate coated with an active catalytic layer. During electrolysis, the anode facilitates the conversion of sodium chloride (NaCl) and water (H₂O) into sodium hypochlorite (NaOCl) and hydrogen gas (H₂).

Technical Specifications of Titanium Anode for Sodium Hypochlorite Generator

|

Parameter |

Typical Range |

|

Base Material |

Titanium (Gr1/Gr2) |

|

Coating |

RuO₂ + IrO₂ + TiO₂ MMO |

|

Current Density |

1000–3000 A/m² |

|

Cell Voltage |

3.0–5.0 V |

|

Operating Temperature |

25–70°C |

|

Electrolyte |

Seawater or Brine |

|

Expected Lifespan |

5–10 years |

|

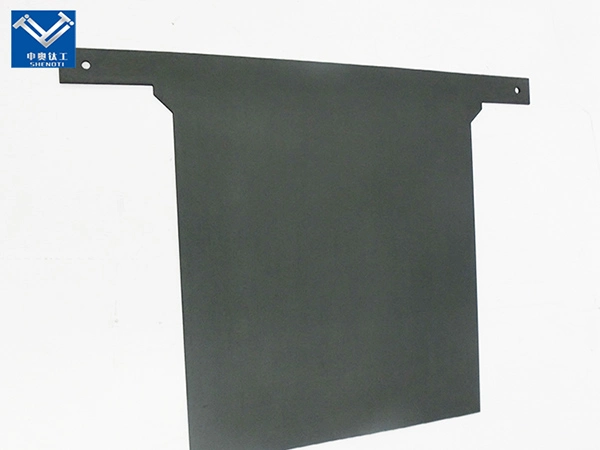

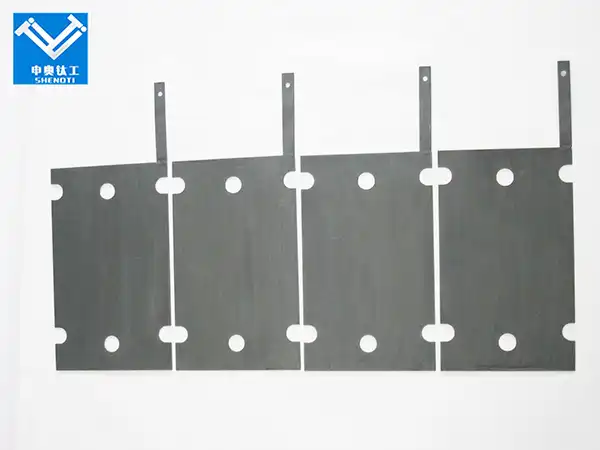

Form |

Plate, Mesh, Tube, or Custom Shapes |

These parameters can be customized depending on generator design, electrolyte composition, and chlorine concentration requirements.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

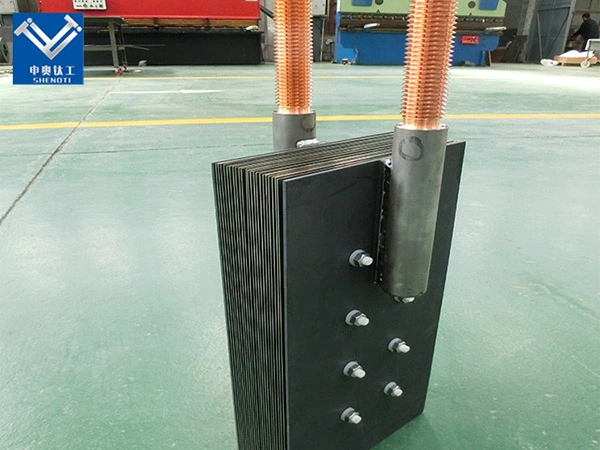

Advantages of Titanium Anode for Sodium Hypochlorite Generator

1. Energy Efficiency

Due to the low overpotential for chlorine evolution, titanium anodes significantly reduce power consumption compared to graphite or DSA (dimensionally stable anodes) alternatives.

2. Stable Chlorine Output

The anode’s catalytic coating ensures consistent sodium hypochlorite concentration even under varying salinity and temperature conditions.

3. Maintenance-Free Operation

Titanium anodes require minimal maintenance, making them ideal for remote or continuous operations such as desalination plants and offshore platforms.

4. Customizable Design

Manufacturers can provide titanium anodes in various geometries—flat, tubular, or mesh—to match the design of sodium hypochlorite cells or compact on-site generators.

Applications of Titanium Anode for Sodium Hypochlorite Generator

1. Seawater Electrolysis Systems

In marine and offshore facilities, titanium anodes are widely used to generate sodium hypochlorite from seawater for biofouling control in cooling systems, pipelines, and ballast water treatment.

2. Industrial Water Disinfection

Factories and chemical plants rely on on-site sodium hypochlorite generators to produce disinfectant solutions for process water sterilization and equipment sanitation.

3. Municipal Water Treatment

Municipal water treatment plants use titanium anodes in electrolytic sodium hypochlorite systems to ensure safe, reliable, and cost-effective chlorination of drinking water.

4. Wastewater Treatment

In wastewater management, titanium anodes are used for oxidation of organic pollutants, ammonia, and heavy metals, as well as for maintaining residual chlorine levels in effluent discharge.

5. Cooling Tower Chlorination

Power plants and industrial facilities use titanium anodes to continuously generate sodium hypochlorite that prevents microbial growth and scaling in cooling towers.

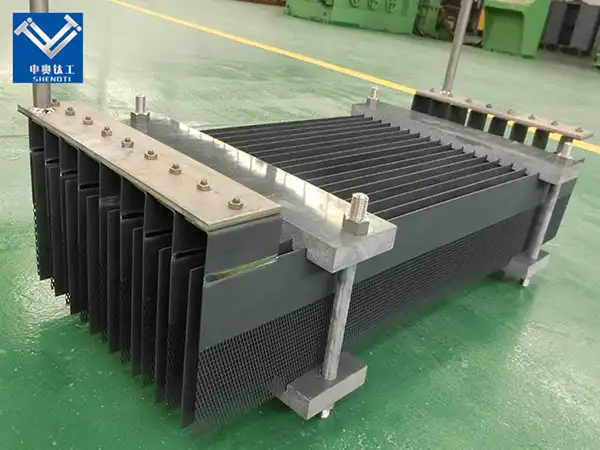

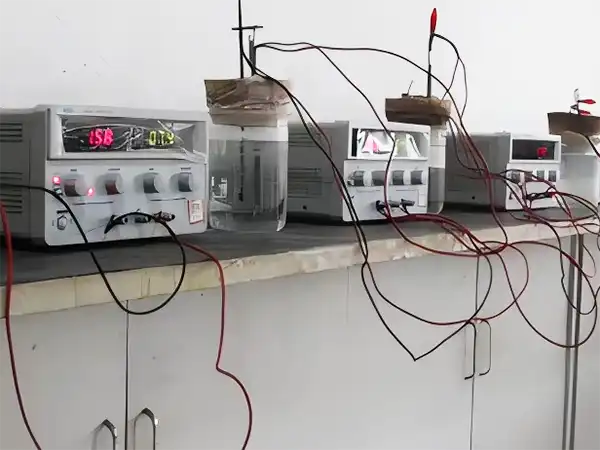

Titanium Anode in a Seawater Sodium Hypochlorite Generator Case:

A major desalination plant in the Middle East installed titanium anodes with Ru-Ir MMO coating in their on-site sodium hypochlorite generation system. The system operated at 2500 A/m² current density for over 8 years without performance decline.

The benefits included:

Reduced maintenance downtime

30% lower energy consumption

Stable chlorine generation efficiency

This case demonstrates how titanium anodes enhance operational reliability and reduce lifecycle costs for critical water treatment infrastructure.

|

|

|

|

|

|

|

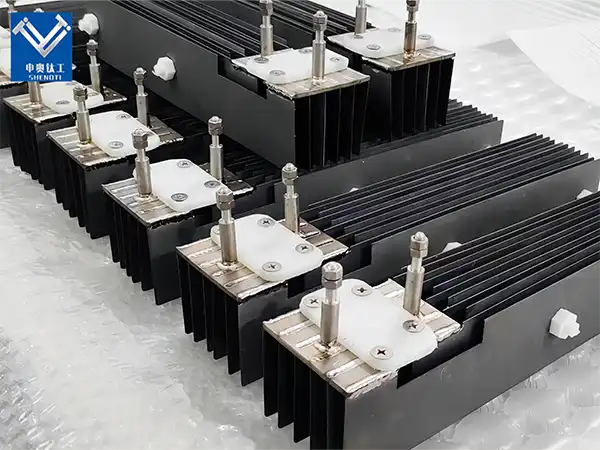

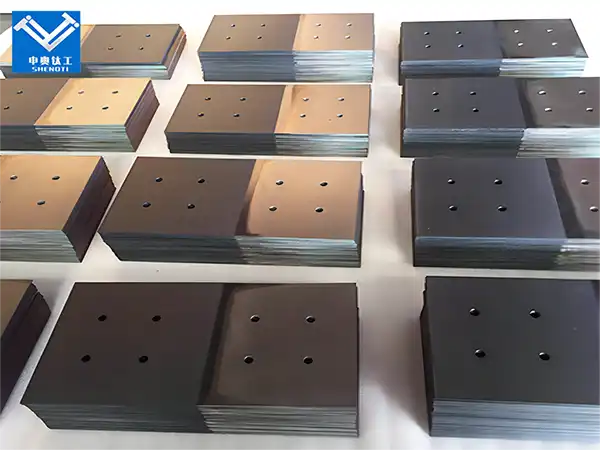

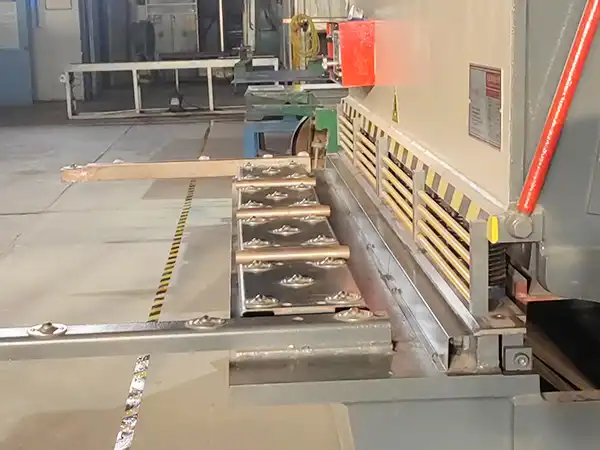

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

1. Research and Innovation

Our expert R&D team continuously improves materials and coatings to deliver state-of-the-art solutions tailored to your needs.

2. Excellent Reputation

With over 17 years of experience, we are a trusted supplier known for our quality and customer-centric approach.

3. Striving for Excellence

Strict quality management and industry-leading standards ensure you receive a product that exceeds expectations.

4. Customized Services

We provide tailored solutions for anodes and other non-ferrous composite materials to meet your specific technical requirements.

5. Timely Delivery & Reliable Support

Our streamlined processes ensure fast order fulfillment and comprehensive after-sales support.

6. OEM Services

Partner with us to develop custom designs that perfectly align with your operational needs.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: How long does the titanium anode last?

A: Depending on usage and conditions, our titanium anodes typically last 5–10 years.

Q2: Can you customize the size and coating?

A: Yes, we offer full customization to meet your specific requirements.

Q3: What industries use this product?

A: Common applications include water treatment, sodium hypochlorite generation, seawater desalination, and industrial disinfection.

Q4: How do I maintain the titanium anode?

A: Regular cleaning to remove scale and debris ensures optimal performance and extends its lifespan.

Contact Us

We’re here to help you find the perfect titanium anode solution. Reach out to us today for a customized quote or technical assistance.

Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

Contact Person: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

This SEO-optimized product page ensures user engagement, boosts your site authority, and increases traffic. For any inquiries about titanium anodes or other high-performance products, don’t hesitate to contact us. We’re committed to delivering reliable and innovative solutions tailored to your needs.

YOU MAY LIKE

_1735287279194.webp)