Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

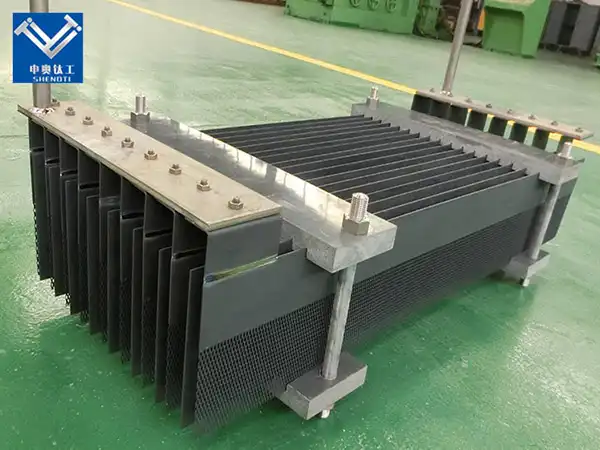

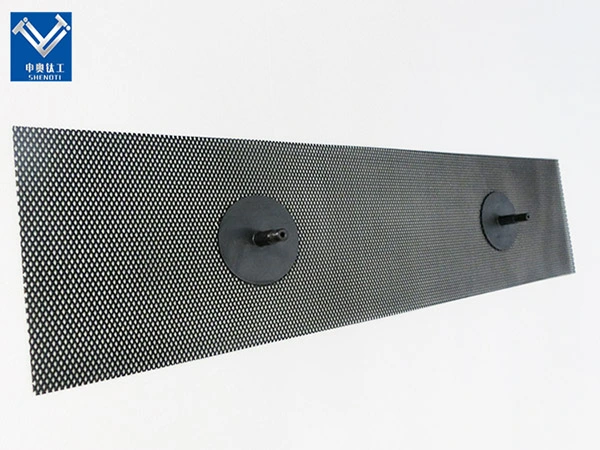

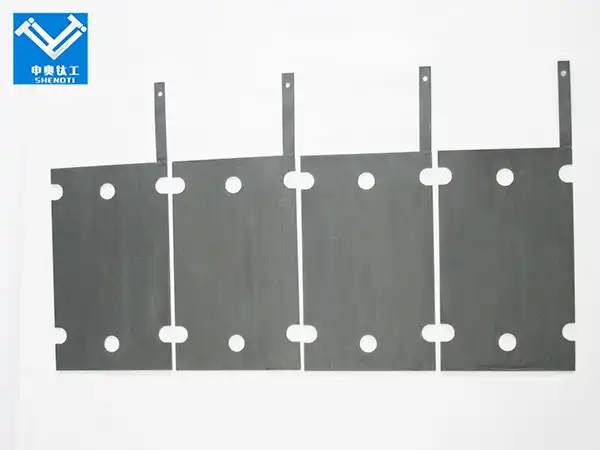

A titanium anode for electrolytic sterilization and disinfection is a specialized electrochemical electrode designed to generate active oxidants (such as chlorine, ozone, and hydroxyl radicals) that effectively kill bacteria, viruses, and algae in water. These anodes are widely used in drinking water purification, swimming pool treatment, food processing, hospital wastewater sterilization, and marine aquaculture systems.

Titanium, known for its excellent corrosion resistance, conductivity, and stability, serves as the base material. The surface is coated with precious metal oxides such as ruthenium oxide (RuO₂), iridium oxide (IrO₂), or platinum (Pt), forming a durable, catalytic layer that ensures efficient electrolysis and long service life.

This technology is a green, chemical-free sterilization solution, replacing traditional chlorine dosing and ultraviolet disinfection. The titanium anode for electrolytic sterilization and disinfection achieves high sterilization rates while reducing secondary pollution and operational costs

Technical Parameters

|

Parameter |

Specification |

|

Base material |

Titanium (Gr1, Gr2) |

|

Coating |

RuO₂-IrO₂, IrO₂-Ta₂O₅, Pt |

|

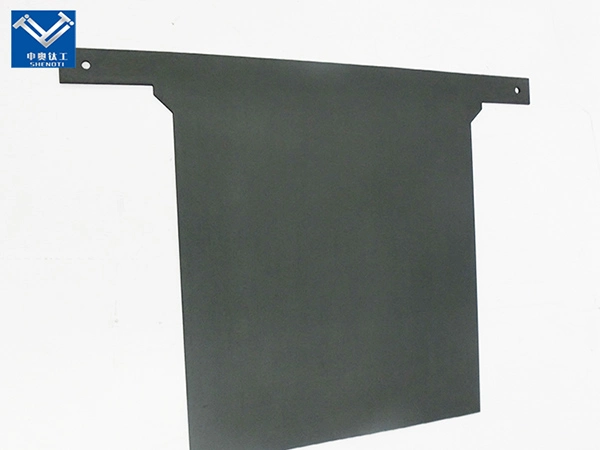

Shape |

Mesh, plate, rod, tubular |

|

Current density |

10–1000 A/m² |

|

Service life |

8000–15000 hours |

|

Operating temperature |

10–60°C |

|

Electrolyte |

NaCl, seawater, wastewater |

|

Sterilization efficiency |

>99.9% |

How Does the Titanium Anode Work in Electrolytic Sterilization?

When current passes through the titanium anode for electrolytic sterilization and disinfection, water molecules and ions undergo oxidation and reduction reactions:

-

At the anode:

2Cl−→Cl2+2e−2Cl^- \rightarrow Cl_2 + 2e^-2Cl−→Cl2+2e−

H2O→O2+4H++4e−H_2O \rightarrow O_2 + 4H^+ + 4e^-H2O→O2+4H++4e− -

At the cathode:

2H++2e−→H22H^+ + 2e^- \rightarrow H_22H++2e−→H2

The generated chlorine (Cl₂), hypochlorous acid (HClO), and hydroxyl radicals (·OH) are powerful oxidants that destroy microbial cell membranes, oxidize organic matter, and inhibit biofilm formation. This process ensures continuous and efficient sterilization even in challenging water conditions.

Advantages of Electrolytic Sterilization

-

No chemical addition: Only electricity and water are required.

-

On-site generation: Disinfectants are produced instantly and locally.

-

Environmentally friendly: No harmful residuals or by-products.

-

Low maintenance: Long lifespan of the titanium anode ensures cost savings.

-

Broad-spectrum efficacy: Effective against bacteria, viruses, and fungi.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Titanium Anode for Electrolytic Sterilization and Disinfection Benefits

1. Long Service Life

Thanks to the robust titanium base and stable oxide coating, the anode can operate over 8000–15000 hours in sterilization systems, depending on the current density and electrolyte composition.

2. High Current Efficiency

The surface coating ensures low overpotential for chlorine and oxygen evolution, providing high current efficiency (>90%) and reducing energy consumption.

3. Excellent Corrosion Resistance

The titanium anode for electrolytic sterilization and disinfection performs reliably in acidic, neutral, or saline environments without corrosion, scaling, or degradation.

4. Customizable Design

Manufacturers can tailor anode shapes—such as mesh, plate, tubular, or rod structures—based on reactor size, flow rate, and sterilization system design.

5 Eco-Friendly Operation

By eliminating chemical disinfectants, the titanium anode helps users meet environmental compliance regulations and reduce chlorine transportation risks.

Titanium Anode for Electrolytic Sterilization and Disinfection Industrial Applications

1. Drinking Water Treatment

Municipal and domestic water systems use titanium anodes for electrolytic sterilization and disinfection to produce safe, bacteria-free water without adding harmful chemicals. The process ensures continuous disinfection in water storage tanks and pipelines.

2. Swimming Pools and Spas

Replacing liquid chlorine, these anodes generate hypochlorous acid (HClO) directly in water, maintaining stable free chlorine concentration and preventing eye or skin irritation for swimmers.

3. Aquaculture and Fisheries

Fish farms use electrolytic sterilization to prevent bacterial infections and algae growth, ensuring a healthy aquatic environment without antibiotic residues.

4. Food and Beverage Industry

Used in CIP (Clean-in-Place) systems, titanium anodes help sterilize production lines, pipes, and storage tanks, ensuring hygienic operations and extending product shelf life.

5. Medical and Pharmaceutical Wastewater

Hospitals and labs use titanium anodes to oxidize pathogens and organic pollutants, reducing biological oxygen demand (BOD) and ensuring wastewater meets discharge standards.

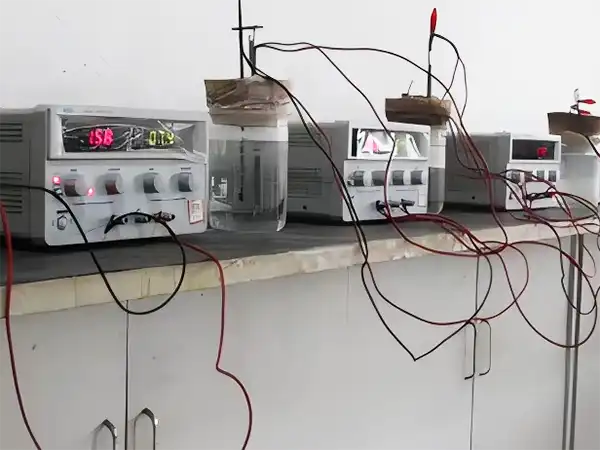

Case Studies

1: Municipal Water Sterilization Project

A Southeast Asian water plant adopted titanium anodes for electrolytic sterilization and disinfection to replace traditional chlorination. The system now operates with 30% lower energy consumption and eliminates the need for bulk chlorine storage.

2: Aquaculture in the Middle East

In marine shrimp farms, titanium anodes generate on-site oxidants to control bacteria and algae. Farmers reported a 20% increase in survival rate and improved water clarity within 30 days of installation.

3: Medical Wastewater Treatment in Europe

A hospital implemented an electrolytic sterilization unit using RuO₂–IrO₂-coated titanium anodes. The result was complete inactivation of E. coli and Staphylococcus aureus, achieving EU wastewater standards.

|

|

|

|

|

|

|

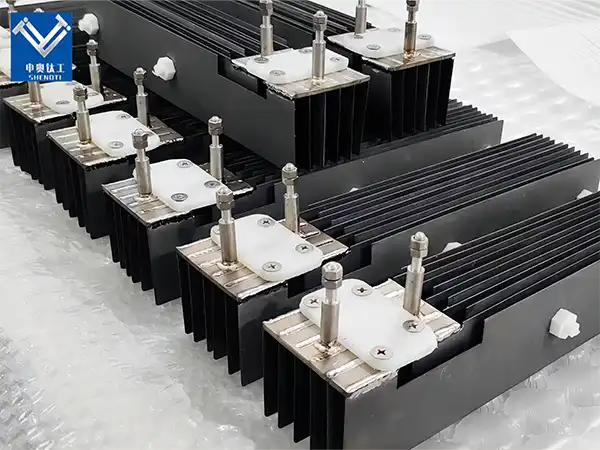

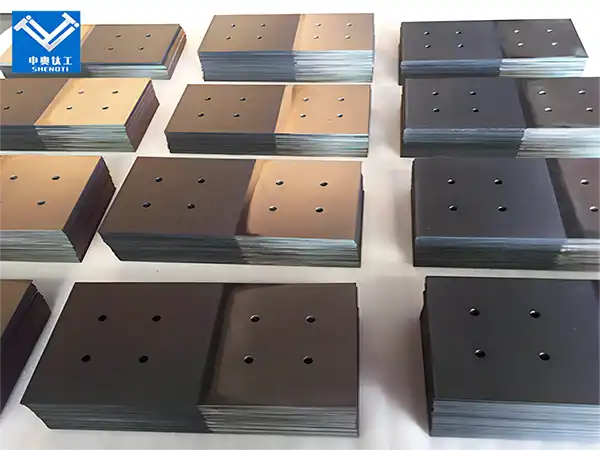

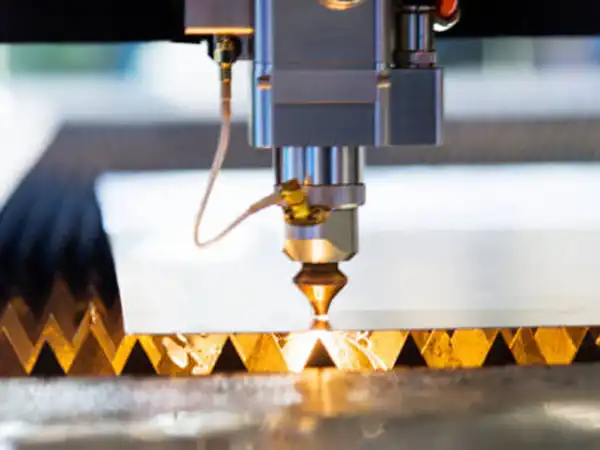

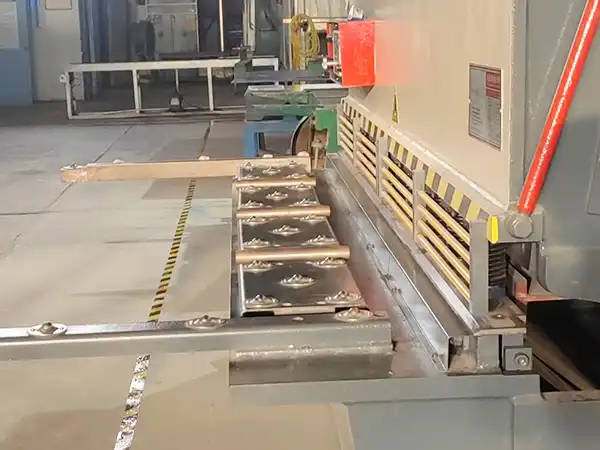

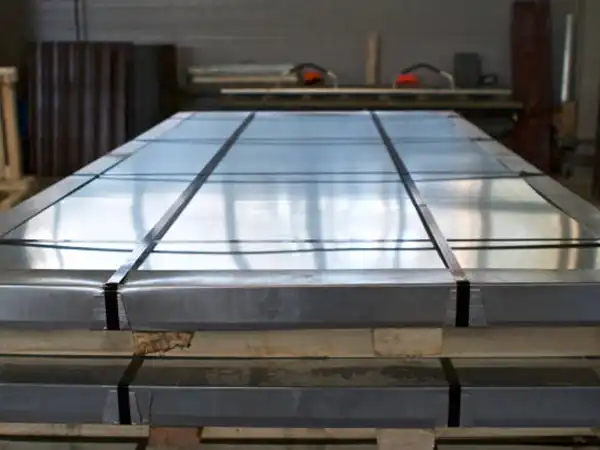

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Baoji Shenao Titanium Anodes for Electrolytic Sterilization and Disinfection?

1. Superior Performance and Durability

Titanium anodes outperform conventional graphite or steel electrodes in both efficiency and lifespan. They maintain stable potential and minimal wear, even under continuous operation.

2. Customization and Technical Support

Professional manufacturers like Baoji City ShenAo Metal Materials Co., Ltd. provide customized titanium anodes tailored to your specific water composition, current density, and reactor configuration.

3. Compliance and Sustainability

The use of titanium anodes aligns with ISO, RoHS, and REACH environmental standards, ensuring sustainable and safe water sterilization without chemical residues.

4. Maintenance and Lifespan Optimization

To maximize the performance of your titanium anode for electrolytic sterilization and disinfection, follow these best practices:

Maintain optimal current density and voltage to avoid over-oxidation.

Periodically clean the anode surface with dilute acid to remove scale or deposits.

Ensure consistent electrolyte flow and temperature to maintain efficiency.

Replace or recoat the anode when potential rise indicates coating wear.

With proper maintenance, a high-quality titanium anode can operate efficiently for 5–8 years in most sterilization systems.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is the lifespan of titanium anodes for electrolytic sterilization?

A1: The service life of titanium anodes typically ranges from 5 to 10 years, depending on the application and operating conditions.

Q2: Can titanium anodes be used in highly acidic or alkaline environments?

A2: Yes, titanium anodes are highly resistant to corrosion, making them suitable for use in a wide range of pH environments, from highly acidic to highly alkaline.

Q3: What is the advantage of using titanium anodes for disinfection over traditional methods?

A3: Titanium anodes produce environmentally friendly disinfectants like hypochlorous acid, which are more effective and safer than traditional chemical disinfectants. They also minimize harmful by-products and reduce the need for maintenance.

Q4: Are your titanium anodes customizable?

A4: Yes, we offer titanium anodes in a variety of sizes and shapes to suit specific project needs. Custom specifications can be requested for optimal performance.

Q5: How do titanium anodes for electrolytic sterilization work?

A5: The titanium anodes generate an electrochemical reaction when powered, which produces disinfectants (such as chlorine) that sterilize water and other liquids. This process effectively kills bacteria, viruses, and other pathogens.

Contact Details

For more information or to place an order, feel free to contact us:

- Company Name: Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City, Shaanxi, China

- Contact Person: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- E-mail: zh@baojiti.com.cn

We are here to provide you with the most professional service and high-quality Titanium anode for electrolytic sterilization and disinfection needs.

YOU MAY LIKE