Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

In the modern electronics and energy industries, titanium anode for aluminum foil formation has become an indispensable component for producing high-quality electrolytic capacitors and electronic materials. The anode’s superior electrochemical stability, corrosion resistance, and long service life make it the preferred choice for forming aluminum electrolytic capacitor foil — a process that directly determines the capacitance, performance, and reliability of the final product.

At Baoji City ShenAo Metal Materials Co., Ltd., we specialize in manufacturing precision-engineered titanium anodes for aluminum foil formation, ensuring stable current distribution, low energy consumption, and excellent oxide film quality for capacitor applications worldwide.

What Is a Titanium Anode for Aluminum Foil Formation?

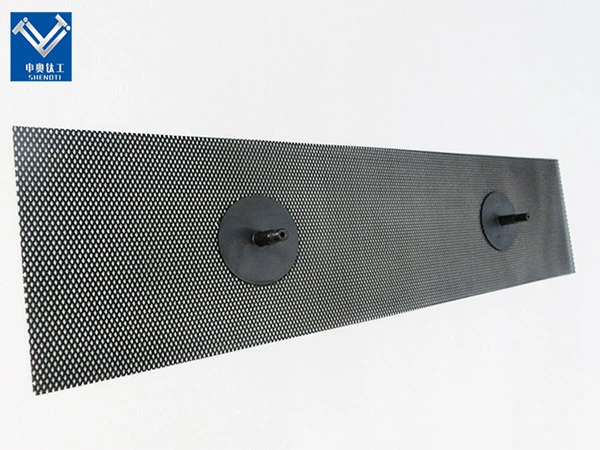

A titanium anode for aluminum foil formation is a specialized electrode used in the electrochemical oxidation process to form an oxide dielectric layer on aluminum foil. This dielectric layer acts as the core insulating barrier in aluminum electrolytic capacitors.

The titanium anode serves as the conductive substrate, typically coated with an active oxide layer such as IrO₂, RuO₂, Ta₂O₅, or mixed DSA (Dimensionally Stable Anode) coatings. These coatings are crucial for achieving high electrochemical efficiency and preventing contamination during the foil formation process.

Technical Specifications of Titanium Anode for Aluminum Foil Formation

|

Parameter |

Specification |

|

Base Material |

Pure Titanium (Gr1 / Gr2) |

|

Coating Type |

MMO (IrO₂ + Ta₂O₅ / RuO₂ + IrO₂) |

|

Coating Thickness |

5–10 µm |

|

Operating Voltage |

Up to 20 V |

|

Current Density |

50–500 A/m² |

|

Service Life |

5–10 years (depending on use conditions) |

|

Forming Electrolyte |

Boric acid / Ammonium borate solution |

|

Application |

Aluminum foil dielectric formation for capacitors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Titanium Anode for Aluminum Foil Formation

1. Excellent Corrosion Resistance

The MMO-coated titanium anode can withstand the harsh chemical environment of aluminum foil forming solutions, preventing dissolution or contamination that could affect the quality of the foil.

2. Extended Service Life

Compared to graphite or lead anodes, titanium anodes offer service lives exceeding five to ten years, greatly reducing maintenance frequency and production downtime.

3. High Efficiency and Energy Savings

The low overpotential and high catalytic activity of the titanium anode reduce energy consumption, enabling cost-effective and environmentally friendly operation.

4. Stable Film Formation Quality

Uniform current density ensures consistent oxide film thickness across the aluminum foil, improving the capacitor’s reliability and performance.

5. Eco-Friendly and Safe

Unlike lead-based anodes, titanium anodes contain no toxic materials, meeting environmental regulations and supporting sustainable manufacturing.

Applications of Titanium Anode for Aluminum Foil Formation

1. Aluminum Electrolytic Capacitor Manufacturing

The primary application of titanium anodes is in the production of anode foil for aluminum electrolytic capacitors used in consumer electronics, automotive electronics, and industrial equipment.

2. Power Electronics and Energy Storage

Titanium anodes are critical in forming foils for high-voltage capacitors used in renewable energy systems, inverters, and power conversion equipment.

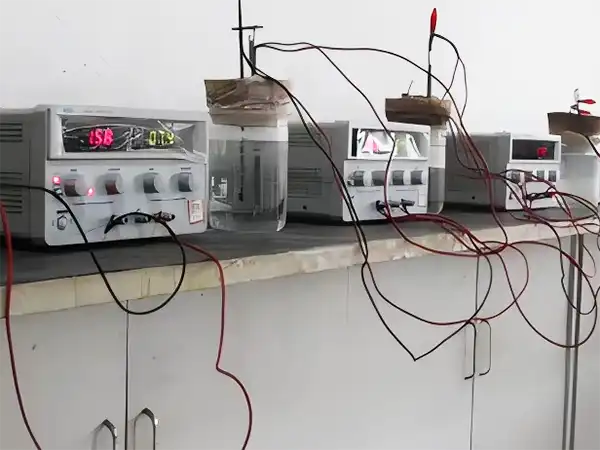

3. Research and Laboratory Use

R&D facilities and laboratories utilize titanium anodes for pilot-scale foil formation experiments and electrochemical testing of new dielectric materials.

Titanium Anode for Aluminum Foil Formation Success Stories:

A leading capacitor manufacturer in South Korea adopted Baoji ShenAo titanium anodes for aluminum foil formation lines. After replacing conventional lead anodes, the plant achieved:

20% increase in foil yield

15% reduction in power consumption

Zero contamination defects in capacitor performance testing

This case demonstrates the superior technical and economic advantages of titanium anodes in modern capacitor production systems.

|

|

|

|

|

|

|

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

At Baoji City ShenAo Metal Materials Co., Ltd., we offer numerous advantages that set us apart from other suppliers:

1. Research and Innovation

Our dedicated R&D team works tirelessly to develop new technologies and processes that meet the unique needs of our clients. We constantly strive for innovation to enhance product performance and efficiency.

2. Excellent Reputation

With over 17 years in the industry, we have earned a stellar reputation for delivering high-quality products and exceptional customer service. Our brand, Olympic Bid Titanium, is trusted by clients worldwide.

3. Striving for Excellence

Our commitment to excellence ensures that every titanium anode we produce meets the highest industry standards. We focus on quality control and stability, ensuring reliable products every time.

4. Customized Product Services

We offer tailored solutions to meet your specific requirements. Whether you need a particular size, coating, or configuration, we provide flexible customization options to suit diverse applications.

5. Timely Delivery and Worry-Free After-Sales Service

Our efficient supply chain ensures prompt delivery of orders, and our after-sales support ensures your complete satisfaction with our products.

6. OEM Services

We also provide OEM services, enabling businesses to have products branded with their names, ensuring they meet specific technical and design requirements.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customersOur Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

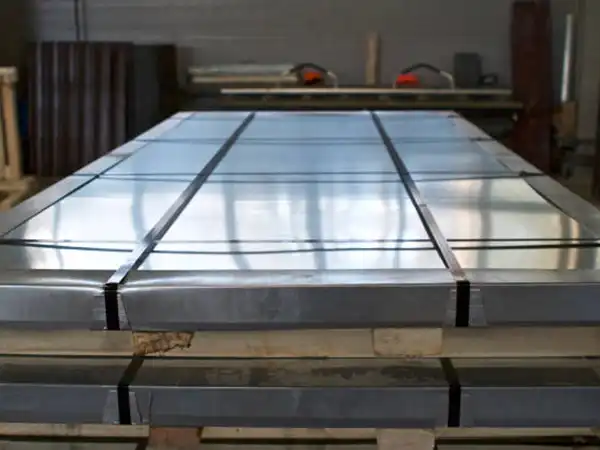

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

1. What is the lifespan of a titanium anode for electrolytic metal?

Our titanium anodes have an impressive lifespan due to their resistance to corrosion, typically lasting many years in normal operating conditions.

2. Can the titanium anodes be customized?

Yes, we provide full customization services to meet your specifications for size, coating, and shape.

3. What are the main applications for titanium anodes?

Titanium anodes are used in metal electroplating, seawater desalination, wastewater treatment, and other industrial processes requiring electrolysis.

4. What coatings do you offer for titanium anodes?

We offer various coatings, including ruthenium, iridium, and platinized coatings, to enhance the anode’s performance and resistance to corrosion.

5. Do you provide technical support for installation and operation?

Yes, we provide technical assistance to ensure your products are installed and operate efficiently.

Contact Details

For more information or to place an order, feel free to contact us:

Company Name: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City, Shaanxi, China

Contact Person: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

E-mail: zh@baojiti.com.cn

Feel free to contact us for more information about our electrode made of titanium oxides and to discuss your specific requirements. We are here to provide you with the most professional service and innovative solutions tailored to your needs.

YOU MAY LIKE