High stability for long-term electrochemical performance.

Durable iridium coating enhances electrode lifespan.

Superior conductivity for efficient energy transfer.

Customizable sizes for various industrial applications.

What Is a Titanium Anode for Electrodeposition?

Titanium anode for electrodeposition is a specialized electrode composed of a titanium substrate coated with catalytic electroactive materials, such as platinum, iridium oxide, or ruthenium oxide. These anodes function as the positive electrode in an electrolytic cell, enabling the controlled deposition of metal ions onto a cathodic workpiece.

Why Titanium as a Substrate?

Titanium is selected for its outstanding properties:

Exceptional corrosion resistance in aggressive acidic and alkaline environments

High mechanical strength and formability

Biocompatibility and environmental safety

Electrical conductivity when paired with appropriate coatings

By coating titanium with noble metal oxides, its inert base becomes highly conductive and catalytically active for anodic reactions, making it ideal for electrodeposition.

Titanium Anode for Electrodeposition Technical Specifications

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

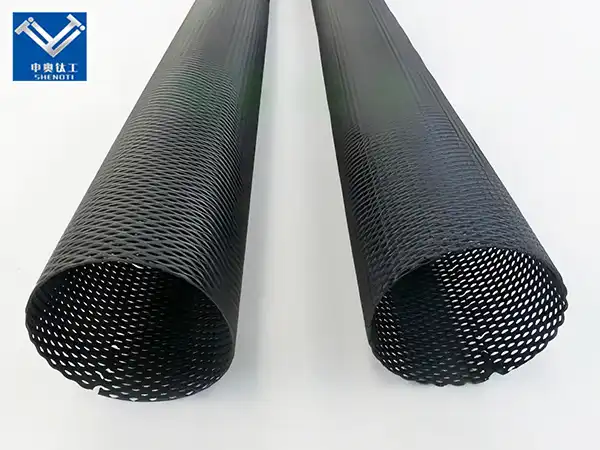

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

Titanium Anode for Electrodeposition Technical Specifications and Surface Coatings

The performance of a titanium anode for electrodeposition depends largely on its coating material. Common types include:

1. Platinum Coated Titanium Anodes

Suitable for acidic solutions and high current densities

High conductivity and oxidation resistance

Ideal for precious metal plating and laboratory-scale applications

2. Iridium/Tantalum Oxide Coatings (MMO Anodes)

Excellent chlorine evolution performance

Low overpotential

Cost-effective and long-lasting

3. Ruthenium-Based Coated Titanium Anodes

High catalytic activity

Used in oxygen evolution applications

Popular in wastewater treatment and large-scale plating baths

|

|

|

|

|

|

|

|

|

|

Advantages of Using Titanium Anode for Electrodeposition

1. Corrosion Resistance

The titanium substrate is nearly immune to corrosion in most electrolytic environments, even in chloride-rich or acidic solutions.

2. Long Service Life

With proper Mixed Metal Oxide (MMO) coatings, titanium anodes can last up to 5–10 years, significantly reducing maintenance costs and downtime.

3. Energy Efficiency

Titanium anodes offer low overpotential during electrochemical reactions, decreasing power consumption and improving plating efficiency.

4. High Purity of Deposit

Titanium is non-contaminating and inert, ensuring high-quality metal deposits without impurity interference.

5. Shape and Design Versatility

They can be manufactured in multiple geometries: mesh, rod, plate, or tubular—optimized for specific electrodeposition cell designs.

Applications of Titanium Anode in Electrodeposition

1. Electroplating Industry

Titanium anodes are widely used in electroplating processes involving metals like copper, nickel, chromium, and precious metals.

Copper electrodeposition for printed circuit boards (PCBs)

Nickel plating for automotive and aerospace components

Gold and silver plating for decorative and electronic applications

2. Electronics Manufacturing

In PCB fabrication, the titanium anode for electrodeposition ensures uniform deposition of conductive layers, crucial for reliable electronic performance.

3. Aerospace and Defense

Precision components in aerospace benefit from titanium anode-based electrodeposition due to the high adhesion and uniformity of metal coatings on intricate geometries.

4. Water Treatment and Environmental Applications

Titanium anodes are used in electrochemical oxidation (EO) and electrocoagulation systems for the removal of pollutants and heavy metals.

|

|

|

|

|

|

|

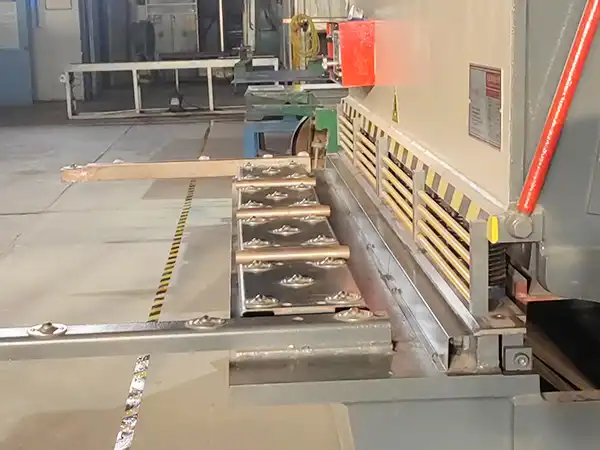

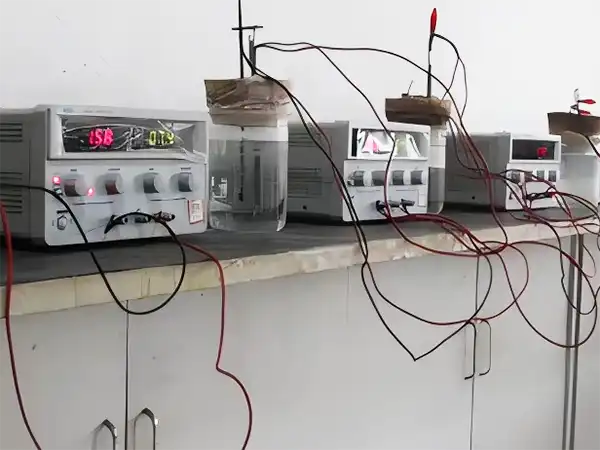

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

-

Research and Innovation

Our experienced R&D team constantly explores new processes and applications, ensuring that our products stay at the cutting edge of technology. We strive for continuous improvement, meeting the evolving needs of our customers. -

Excellent Reputation

With 17 years of industry experience, Baoji City ShenAo Metal Materials Co., Ltd. has earned a stellar reputation for delivering high-quality products and reliable customer service. Our titanium anodes are trusted worldwide. -

Striving for Excellence

Our commitment to excellence is reflected in our meticulous production processes and comprehensive quality management system. Every product meets the highest industry standards, ensuring long-lasting performance. -

Customized Product Services

We offer tailored solutions to meet the unique requirements of various industries. Whether you need specific dimensions, coatings, or designs, we deliver customized titanium anodes that fit your needs perfectly. -

Timely Delivery and Worry-Free After-Sales Service

We prioritize customer satisfaction, offering fast delivery and robust after-sales support. Our dedicated team is always available to assist with any inquiries or issues that may arise. -

OEM Services

We provide original equipment manufacturer (OEM) services to help businesses customize their products with precision. Our team works closely with clients to ensure that each order meets their specific needs.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

-

What is the expected service life of your titanium anodes?

Our titanium anodes are designed for a service life of up to 10 years, depending on the application and operating conditions. -

Can you customize the size and coating of the titanium anodes?

Yes, we offer customizable sizes and coatings, including Ruthenium and Iridium, to meet specific customer requirements. -

Are your titanium anodes suitable for use in seawater desalination?

Absolutely! Our titanium anodes are highly resistant to corrosion, making them ideal for seawater desalination systems. -

What industries use titanium anodes for electrodeposition?

Titanium anodes are used in a wide range of industries, including electroplating, electrowinning, environmental protection, and more. -

How can I place an order for titanium anodes?

You can contact us directly for quotations, orders, or any further inquiries about our products. Our team is happy to assist you.

Contact Us

We are committed to providing the highest level of service and support to our clients. For more information or to place an order, please contact us:

- Company Name: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City, Shaanxi, China

- Contact Person: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

We look forward to helping you meet your material and electrochemical needs with our advanced titanium anodes for electrodeposition!

By following SEO best practices, this page is optimized for search engines while offering a valuable resource for potential customers. We hope it drives traffic, enhances user engagement, and increases conversions!

YOU MAY LIKE

_1735889823558.webp)