Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

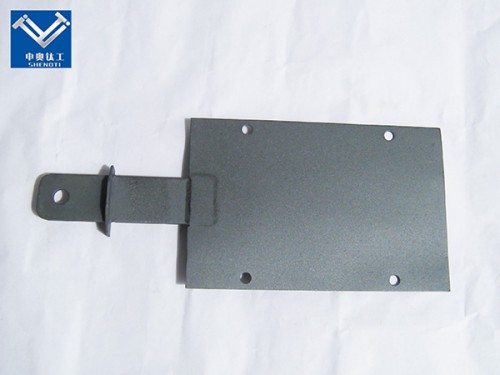

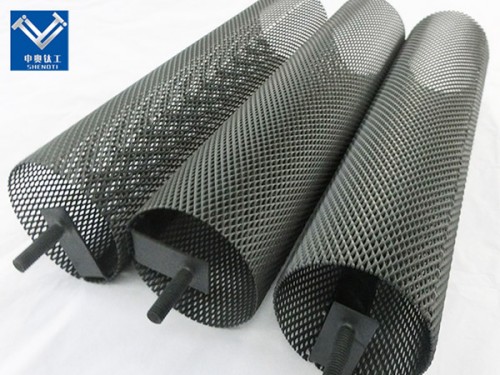

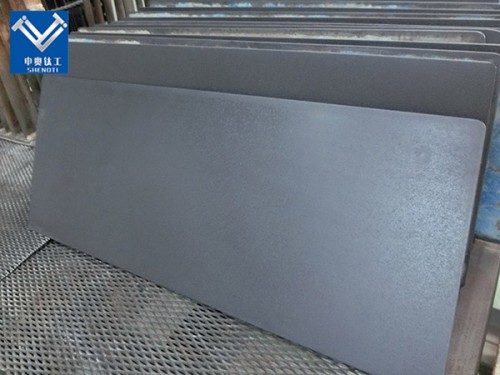

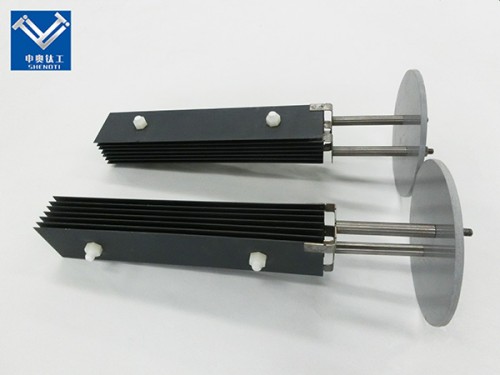

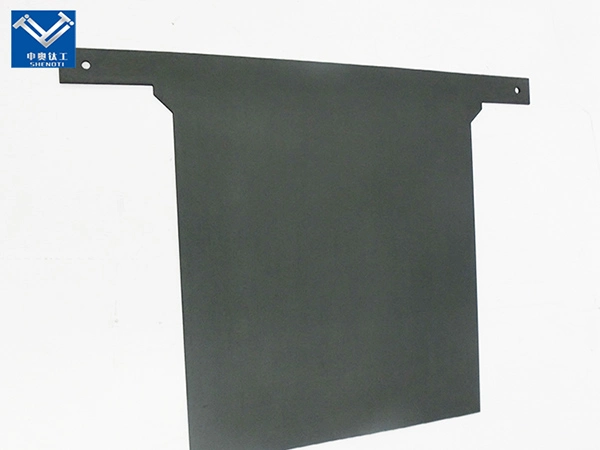

Customizable sizes for various industrial applications.

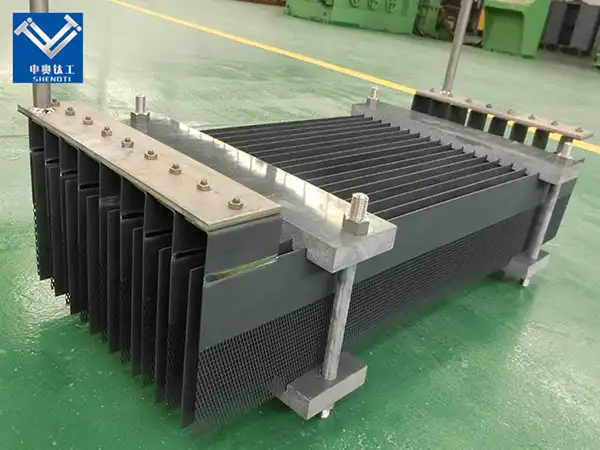

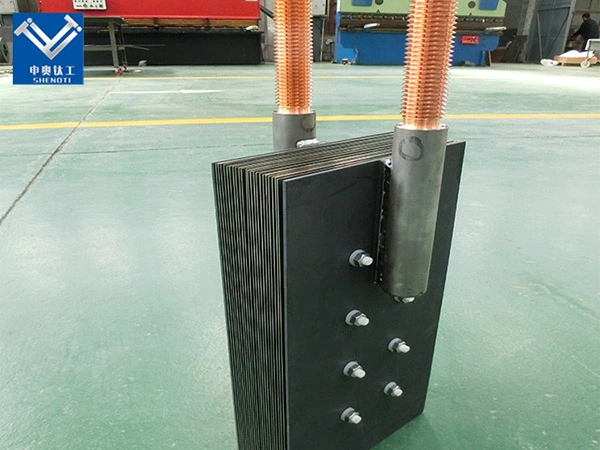

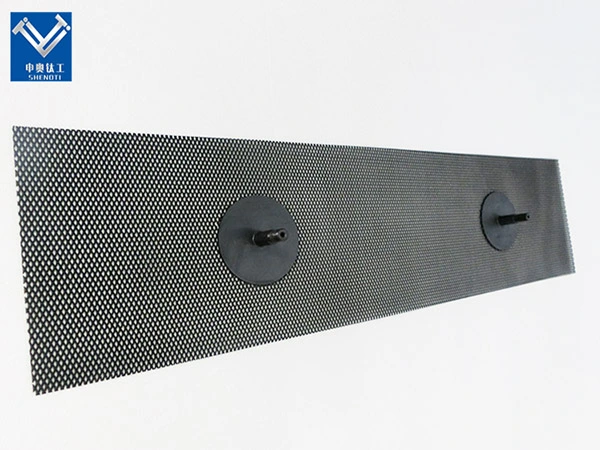

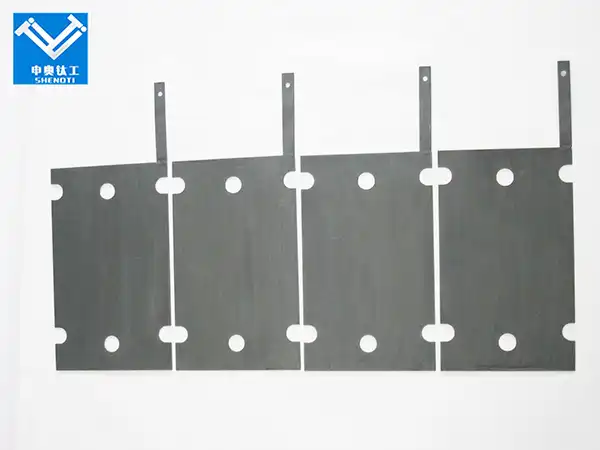

Titanium Anode for Alkaline Water Electrolysis

Titanium anodes for alkaline water electrolysis are cutting-edge solutions designed for energy-efficient hydrogen production and other electrochemical processes. These high-performance anodes feature excellent corrosion resistance, long operational life, and superior conductivity, making them ideal for alkaline water electrolyzers. Baoji City ShenAo Metal Materials Co., Ltd., located in the heart of China’s Titanium Valley, brings decades of expertise in producing advanced titanium anodes tailored to meet the demanding requirements of chemical, energy, and environmental industries.

Technical Parameters of Titanium Anode for Alkaline Water Electrolysis

|

Parameter |

Typical Value |

|

Substrate Material |

Titanium (Grade 1 or Grade 2) |

|

Coating Composition |

RuO₂–IrO₂–Ta₂O₅ or NiO–Fe₂O₃ |

|

Operating Voltage |

1.6 – 2.0 V |

|

Current Density |

200 – 1000 mA/cm² |

|

Electrolyte |

KOH or NaOH (20–40%) |

|

Service Life |

5 – 10 years |

|

Operating Temperature |

60 – 90°C |

These parameters can be customized based on the customer’s specific electrolysis system requirements.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key Advantages of Titanium anode for alkaline water electrolysis:

- Superior Corrosion Resistance

Titanium’s inherent resistance to corrosion ensures durability, even in highly alkaline environments. - High Electrical Efficiency

Coated with noble metals like ruthenium and iridium, the anode minimizes energy loss and enhances operational efficiency. - Tailored Design

Available in custom sizes and configurations to suit diverse industrial applications. - Environmental Sustainability

Enables clean hydrogen production, aligning with energy-saving and eco-friendly initiatives. - Cost-Effective

Long service life reduces maintenance costs and operational downtime.

Applications of Titanium Anodes in Alkaline Water Electrolysis

1. Hydrogen Production

The most important application is in green hydrogen production, where renewable energy sources (solar, wind, or hydro) power the electrolysis process. Titanium anodes ensure high-efficiency oxygen generation and minimal energy loss, directly influencing the hydrogen output rate.

2. Chlor-Alkali Industry

In addition to hydrogen production, titanium anodes are widely used in chlor-alkali cells for producing chlorine (Cl₂), sodium hydroxide (NaOH), and hydrogen (H₂). Their stability and resistance to chloride corrosion make them ideal for these harsh environments.

3. Water Treatment and Electrochemical Oxidation

Titanium anodes are also employed in electrochemical oxidation processes for wastewater treatment, including the removal of organic pollutants and ammonia. Their ability to generate active oxygen species makes them efficient in degrading persistent contaminants.

4. Energy Storage and Fuel Cells

Advanced research has also explored titanium-based electrodes in reversible fuel cells and metal-air batteries. Their chemical stability and conductivity make them a promising component in next-generation energy systems.

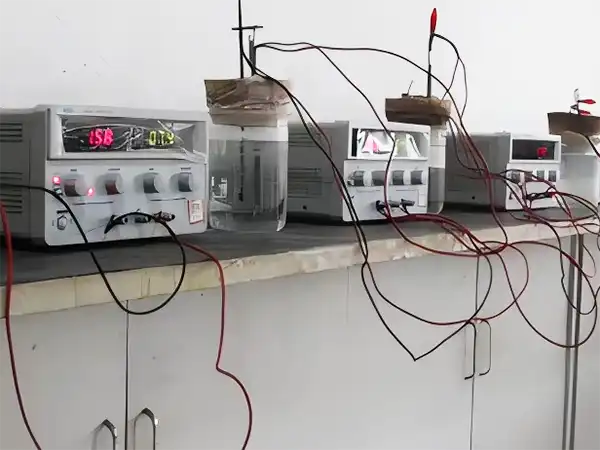

Titanium anode for alkaline water electrolysis Case:

1: 5 MW Alkaline Hydrogen Plant

In a 5 MW hydrogen production project, titanium anodes with IrO₂–Ta₂O₅ coatings were deployed. The system achieved:

Current density: 0.5 A/cm²

Cell voltage: <1.9 V

Operating life: over 30,000 hours

The result was a 15% energy efficiency improvement and a significant reduction in maintenance costs.

2: Wastewater Electrolysis System

A municipal wastewater treatment facility implemented titanium anodes for electrochemical oxidation of COD. The electrodes maintained stable performance for over 24 months with negligible coating degradation, proving their robustness in real-world alkaline environments.

|

|

|

|

|

|

|

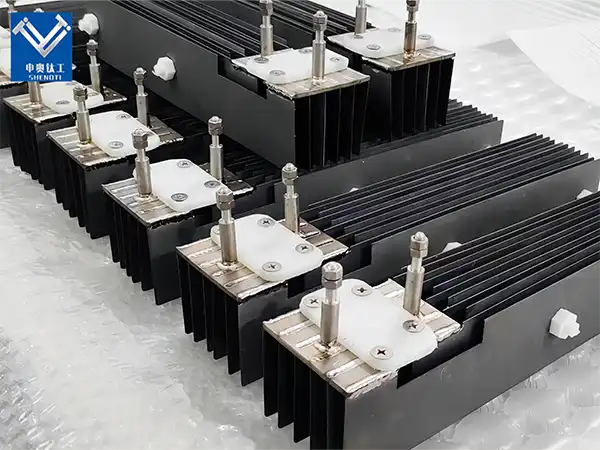

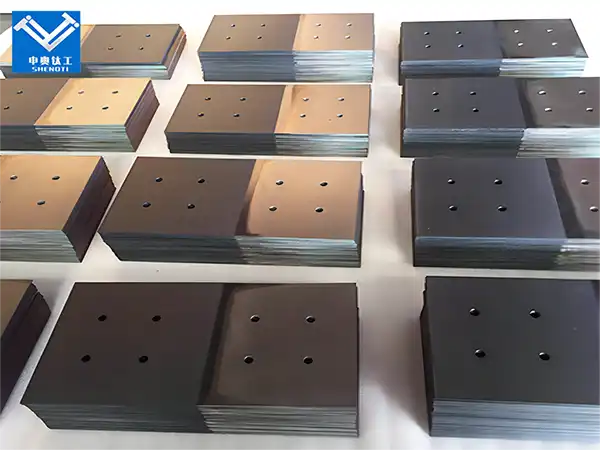

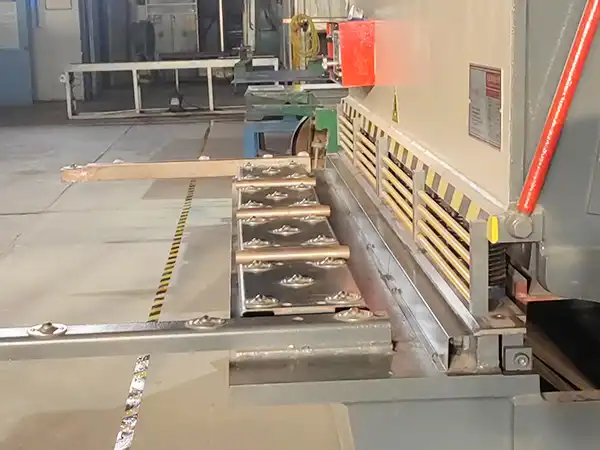

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

-

Research and Innovation

With a dedicated R&D team, Baoji City ShenAo Metal Materials Co., Ltd. continuously enhances its processes to meet evolving market needs. We excel in customizing titanium anodes for diverse industrial applications. -

Proven Reputation

Over 17 years of expertise and a stellar track record in delivering high-quality products have earned us the trust of global clients. -

Commitment to Excellence

A strict quality management system ensures that every product meets rigorous industry standards, whether for small-scale or mass production. -

Customization Services

Tailored solutions for non-standard specifications, including size, coating, and technical properties, to match your exact requirements. -

Timely Delivery and Support

A customer-first approach ensures prompt delivery and responsive after-sales service, providing peace of mind throughout the project lifecycle. -

OEM Services

We collaborate with partners to deliver private-label solutions, catering to diverse market demands.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. What is the lifespan of a titanium anode for alkaline water electrolysis?

With proper maintenance, the anode can last over three years, depending on usage and operating conditions.

2. Can you customize the anode dimensions and coating composition?

Yes, we offer fully customizable solutions to meet specific client needs.

3. How do I maintain the titanium anode?

Regular cleaning and operating within the recommended pH and temperature range will maximize its lifespan.

Contact Details

For inquiries, custom orders, or more information, feel free to reach out to us:

- Company Name: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86-187-2973-1603

- Fax: +86-917-338-0538

- Email: zh@baojiti.com.cn

Transform your alkaline water electrolysis systems with our high-performance titanium anodes. Contact us today for tailored solutions that meet your industrial needs and environmental goals!

YOU MAY LIKE

_1735356385558.webp)