What Is a Bimetallic Aluminum DT4 Clad Plate?

2025-04-16T08:00:00.000Z

In the realm of advanced materials, bimetallic aluminum DT4 clad plates have emerged as a pivotal innovation, combining the advantageous properties of aluminum and DT4 steel. This fusion results in a material that offers exceptional performance in various industrial applications, including chemical processing, power generation, and transportation.

What Is a Bimetallic Aluminum DT4 Clad Plate?

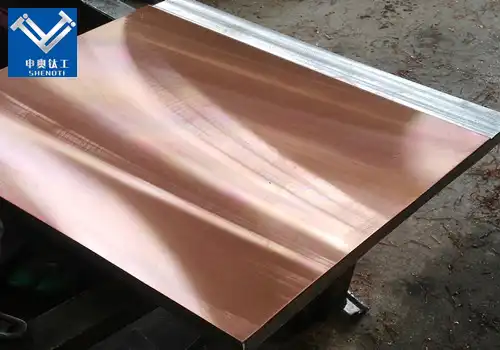

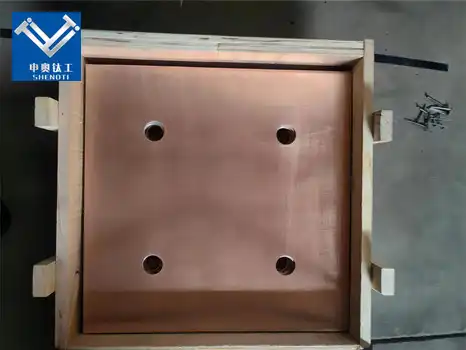

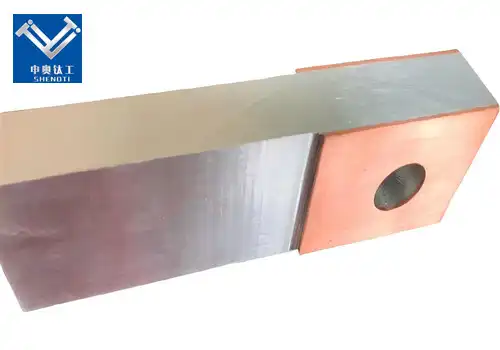

A bimetallic aluminum DT4 clad plate is a composite material consisting of a layer of aluminum bonded to a DT4 steel substrate. DT4 is a type of pure iron known for its excellent magnetic properties and ductility. The combination of aluminum's lightweight and corrosion-resistant characteristics with DT4's magnetic properties results in a material that is both durable and efficient for specific industrial uses.

Composition and Structure

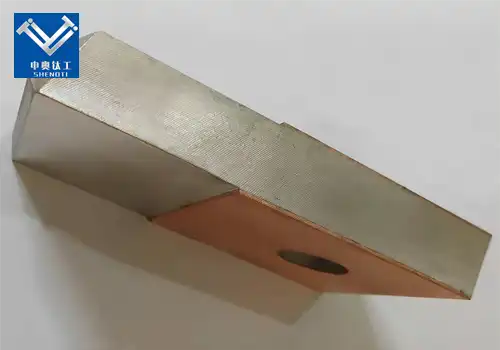

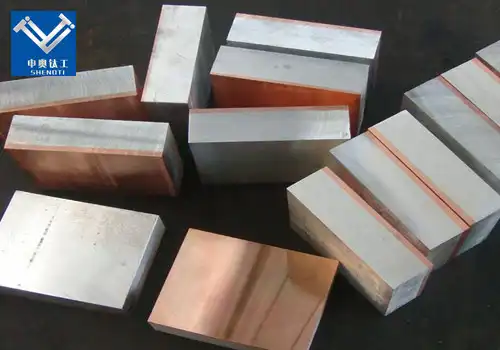

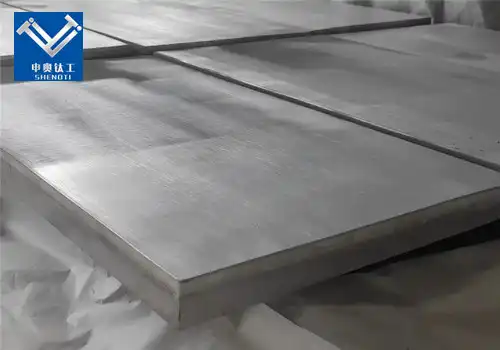

The clad plate typically features a thin layer of aluminum (the cladding) bonded to a thicker layer of DT4 steel (the base). The bonding process ensures a strong metallurgical bond between the two metals, allowing them to act as a single material while retaining their individual properties.

How Is an Aluminum Clad Plate Made?

The manufacturing of aluminum clad plates involves several sophisticated processes designed to ensure a strong bond between the aluminum and steel layers. The primary methods include:

Explosion Bonding

This process involves placing the aluminum and steel plates together and then detonating an explosive charge on one side. The force from the explosion causes the two metals to collide at high velocity, creating a metallurgical bond without melting the materials. Explosion bonding is known for producing high-quality bonds with minimal heat-affected zones.

Roll Bonding

In roll bonding, the aluminum and steel plates are cleaned and then passed through a series of rollers under high pressure. This pressure causes the metals to deform and bond at the interface. Roll bonding is suitable for producing large quantities of clad plates with consistent thickness and quality.

Explosion-Roll Bonding

This hybrid method combines explosion bonding and roll bonding. Initially, the metals are bonded using explosion bonding to create a strong initial bond. Subsequently, the bonded plates are rolled to achieve the desired thickness and surface finish. This method leverages the advantages of both processes, resulting in high-quality clad plates.

What Are the Applications of Aluminum Clad Plates?

Aluminum clad plates are utilized across various industries due to their unique combination of properties. Some notable applications include:

Chemical Processing

In chemical plants, aluminum clad plates are used to construct reactors, heat exchangers, and pressure vessels. The aluminum layer provides excellent corrosion resistance against aggressive chemicals,

Power Generation

Aluminum clad plates are employed in power plants for components like boilers and turbine blades. Their ability to withstand high temperatures and resist corrosion makes them ideal for such demanding environments.

Transportation

In the automotive and aerospace industries, aluminum clad plates are used to manufacture lightweight yet strong components. The reduced weight contributes to fuel efficiency, while the strength ensures safety and durability.

Construction

Aluminum clad plates are used in building facades and roofing due to their aesthetic appeal, corrosion resistance, and ease of maintenance. They provide a modern look while ensuring long-term durability.

What Are the Advantages of Aluminum Clad Plates?

Aluminum clad plates offer several benefits that make them a preferred choice in various industries:

Corrosion Resistance

The aluminum layer acts as a protective barrier against corrosion, extending the lifespan of the component and reducing maintenance costs.

Lightweight

Aluminum is significantly lighter than steel, which helps in reducing the overall weight of structures and components, leading to energy savings and easier handling.

Thermal Conductivity

Aluminum has excellent thermal conductivity, making clad plates effective in heat exchangers and other applications requiring efficient heat transfer.

Cost-Effectiveness

By combining aluminum with steel, clad plates offer a cost-effective solution that leverages the strengths of both metals without the expense of using solid aluminum.

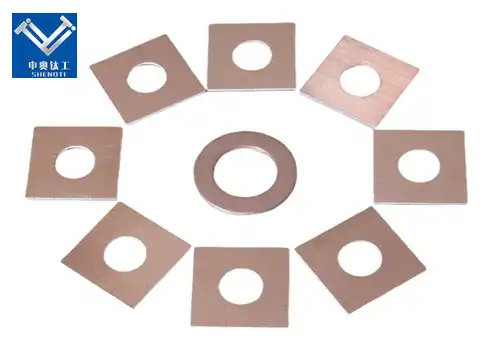

Versatility

Aluminum clad plates can be customized in terms of thickness, size, and alloy combinations to meet specific requirements, making them versatile for various applications.

Contact Us

For more information about bimetallic aluminum DT4 clad plates or to discuss your specific requirements, please contact us at:

Email: zh@baojiti.com.cn

YOU MAY LIKE