High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

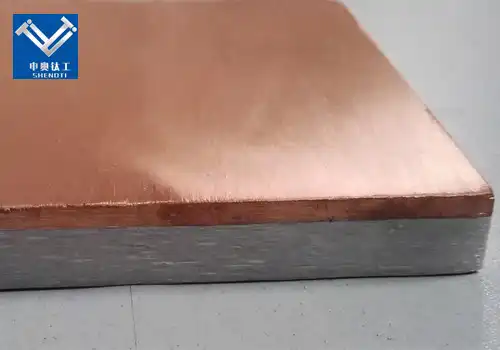

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

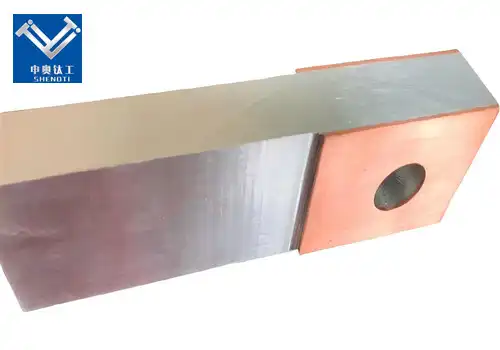

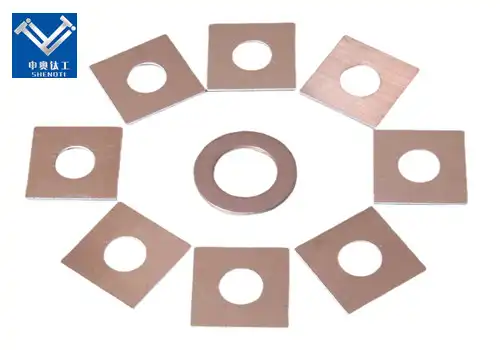

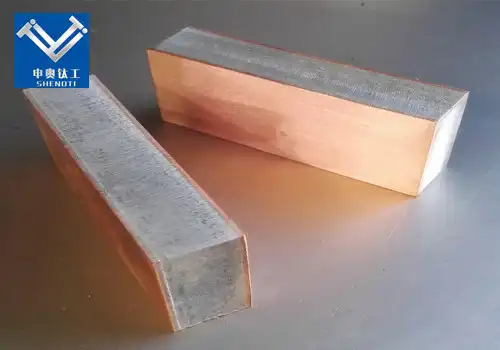

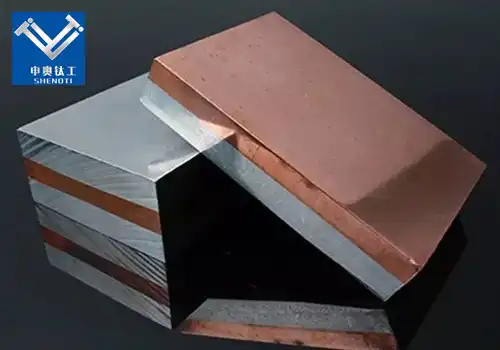

Copper Cladding Aluminum Sheet Transition Joint

Product Introduction

The Copper Cladding Aluminum Sheet Transition Joint is an advanced composite material that combines the superior conductivity of copper with the lightweight and corrosion-resistant properties of aluminum. This innovative material is designed to provide seamless transitions between copper and aluminum components in various industrial applications, ensuring optimal performance and durability. Manufactured using advanced explosive welding technology, this product delivers exceptional mechanical strength, electrical conductivity, and long-term reliability.

Preparation technology of copper-aluminum plate transition joint

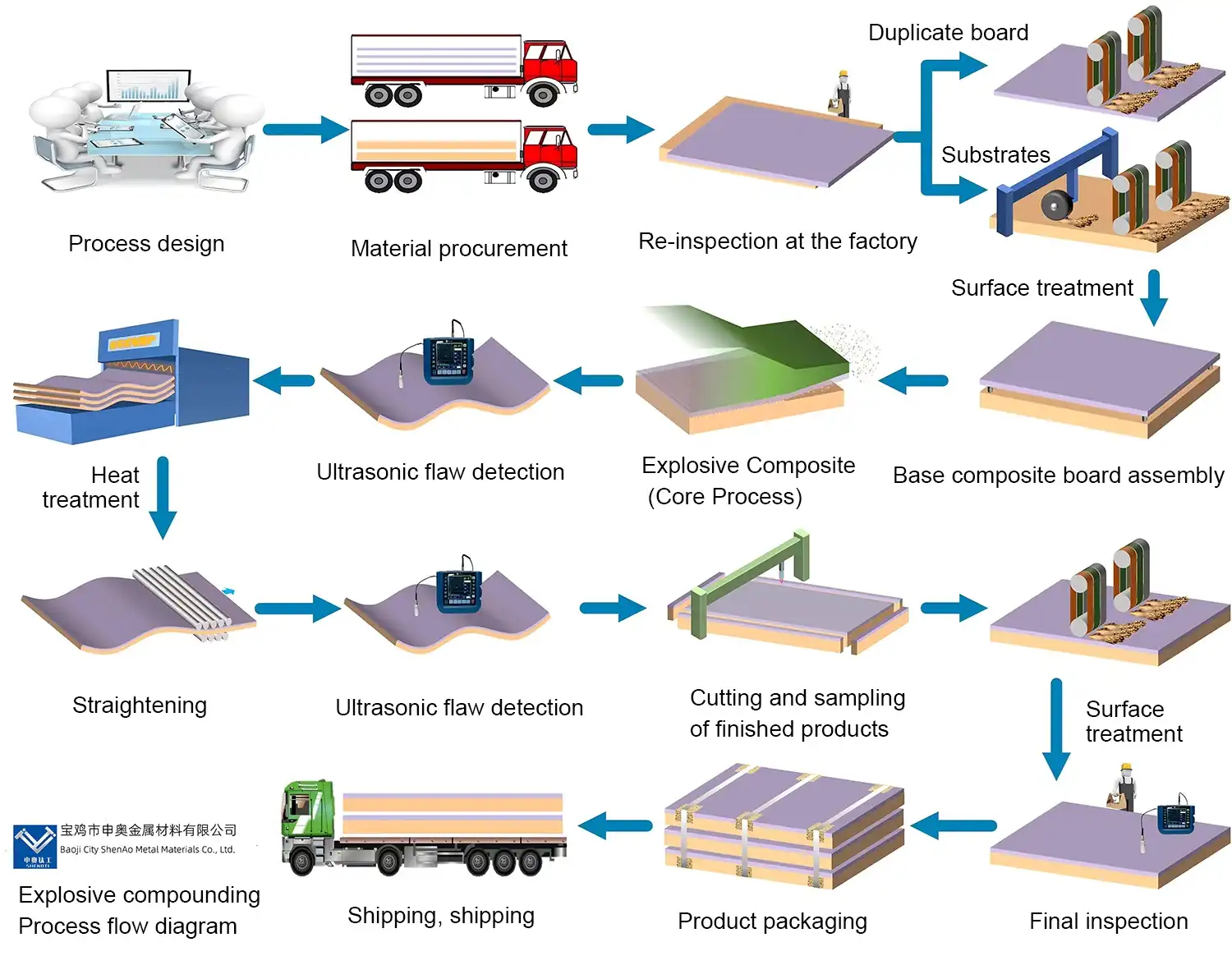

1. Explosive welding method

Explosive welding is a common and mature copper-aluminum composite technology. It uses the instantaneous high energy of explosives to drive the metal plates to collide at high speed and complete metallurgical bonding within nanoseconds. This method has the following characteristics:

High bonding strength and no obvious oxide layer on the interface;

Suitable for large-area plate composite;

Relatively high cost and high safety control requirements.

2. Rolling composite method

Hot rolling or cold rolling is used to physically press the copper plate and the aluminum plate under high pressure. This method is suitable for mass production, but it has strict requirements on surface cleanliness and rolling parameter control. Its advantages are:

The process is relatively safe;

Suitable for thin plate composite;

The interface bonding quality is slightly lower than explosive welding.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Composition | Copper (C11000) + Aluminum (AA 1350/6061) |

| Bonding Technique | Explosive Welding |

| Thickness (Copper Layer) | 0.5mm – 10mm |

| Thickness (Aluminum Layer) | 1mm – 100mm |

| Width | 1000mm |

| Length | Customizable |

| Electrical Conductivity | ≥99% IACS (Copper Layer) |

| Corrosion Resistance | Excellent |

| Operating Temperature Range | -50°C to 300°C |

| Certification | ISO 9001, ASTM B898 |

|

|

|

|

|

|

Advantages of copper-aluminum plate transition joint

1. Bridge between dissimilar metals

The greatest value of the copper-aluminum plate transition joint is that it establishes a stable "bridge" between copper and aluminum, avoiding electrochemical corrosion caused by direct connection. Copper and aluminum are far apart in the electrochemical sequence. Direct connection is very likely to produce corrosion reactions due to potential difference, while the composite interface formed by the copper-aluminum plate transition joint avoids this problem.

2. Improve the efficiency of conduction

The copper-aluminum plate transition joint can effectively reduce the contact resistance and ensure the stability of current transmission. Under high current conditions, such as the substation busbar connection system, the use of copper-aluminum plate transition joints can reduce power loss and improve operating efficiency.

3. Reduce costs and lightweight structure

The density of aluminum is only one-third of that of copper, and the price is also lower. Through the copper-aluminum plate transition joint, part of the copper material is replaced by aluminum, which not only reduces the overall material cost, but also reduces the weight of the structure, which is conducive to the miniaturization of equipment and energy conservation and emission reduction.

Application areas of copper-aluminum plate transition joints

1. Power transmission and distribution system

In high-voltage power transmission and transformation equipment, a large number of copper-aluminum plate transition joints are used to connect aluminum cables with copper busbars and terminal blocks. This connection method not only ensures stable electrical performance, but also effectively extends the life of the equipment.

2. Electrolysis and metallurgical industry

In the electrolytic cell plate system, copper is used for conduction and aluminum is used for structural support. The transition through the copper-aluminum plate transition joint can meet the dual needs of conductivity and mechanical strength at the same time.

3. New energy vehicles and energy storage systems

In new energy vehicle power battery packs, BMS systems, and energy storage modules, copper-aluminum transition joints are used to connect battery copper bars and aluminum shells to achieve efficient and safe conductive channels, which is an important part of lightweight electric system design.

|

|

|

|

|

|

|

Product production process

Why Choose Us

1. Research and Innovation

At Baoji City ShenAo Metal Materials Co., Ltd., we have a dedicated research and development team committed to exploring new processes and applications. Our continuous innovation ensures that we provide cutting-edge solutions tailored to our clients' needs.

2. Excellent Reputation

With over 17 years of experience, we have established a strong reputation for delivering high-quality products and reliable customer service. Our brand is trusted and praised by clients worldwide.

3. Striving for Excellence

Our strict production processes and comprehensive quality management system guarantee that every product meets the highest standards. Whether for small-batch testing or large-scale production, we deliver on time with consistent quality.

4. Customized Product Services

We offer fully customized solutions, tailoring our Copper Cladding Aluminum Sheet Transition Joints to specific client requirements and technical needs.

5. Timely Delivery & Worry-Free After-Sales

Our customer-centric approach ensures prompt delivery and exceptional after-sales support. We are always ready to address your concerns and provide solutions.

6. OEM Services

We provide OEM services to cater to diverse client needs, ensuring seamless integration into their projects.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is the lifespan of the Copper Cladding Aluminum Sheet Transition Joint? A1: With proper installation and use, the product can last for decades, thanks to its excellent corrosion resistance and robust bonding.

Q2: Can the dimensions be customized? A2: Yes, we provide customizable dimensions to meet specific application requirements.

Q3: How does the product prevent galvanic corrosion? A3: The explosive welding process ensures a strong bond and reduces the risk of galvanic corrosion between copper and aluminum layers.

Contact Details

We are dedicated to providing the most professional service for your metal product needs. Contact us today for more information.

-

Name: Baoji City ShenAo Metal Materials Co., Ltd

-

Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

-

Contact: Wang Shujuan

-

Phone: +86-18729731603

-

Fax: +86-917-3380538

-

Email: zh@baojiti.com.cn

Let us help you find the perfect solution for your industrial applications!