High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

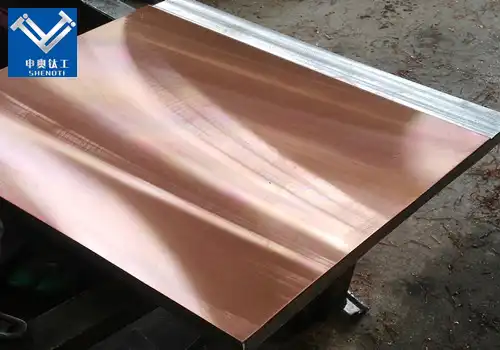

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

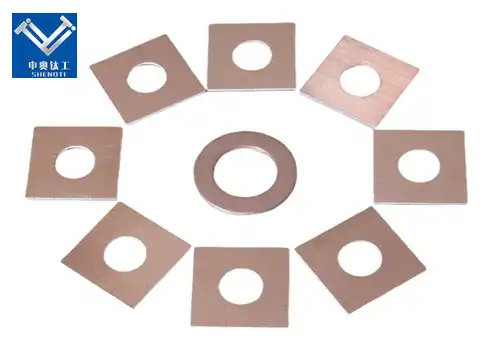

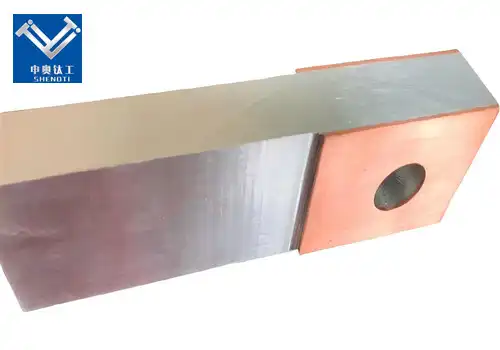

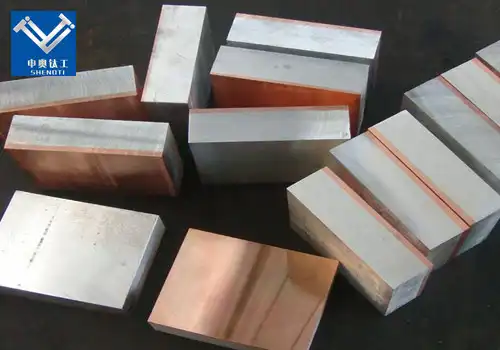

Copper Aluminum Bimetallic Gasket Product Details

Product Introduction

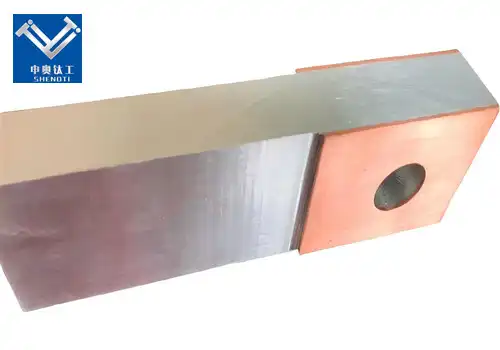

Copper-aluminum bimetallic gasket is a high-performance sealing element made of copper and aluminum through explosive welding, rolling and compounding processes. It usually has a ring, rectangular or special-shaped structure and can be customized according to different flanges or equipment interfaces. The combination of the two metals not only improves the overall performance of the gasket, but also overcomes the application limitations of a single metal material under high temperature, high pressure and strong corrosion conditions.

Copper-aluminum bimetallic gasket thickness ratio

The composite ratio of copper-aluminum bimetallic gasket can be adjusted according to specific needs. The common thickness ratio is copper: aluminum = 1:3 or 1:4, such as 1mm copper + 3mm aluminum or 2mm copper + 8mm aluminum. This not only ensures the performance of the conductive layer, but also controls the overall weight and cost.

Technical Specifications

| Parameter | Value |

|---|---|

| Material Composition | Copper (Outer Layer), Aluminum (Inner Core) |

| Conductivity | High (Copper side), Moderate (Aluminum side) |

| Operating Temperature | -40°C to 200°C |

| Pressure Resistance | Up to 500 MPa |

| Thickness Range | 1mm – 3mm |

| Corrosion Resistance | Excellent in saline and acidic environments |

| Bonding Strength | > 30 MPa |

| Customization | Available for size, shape, and material ratios |

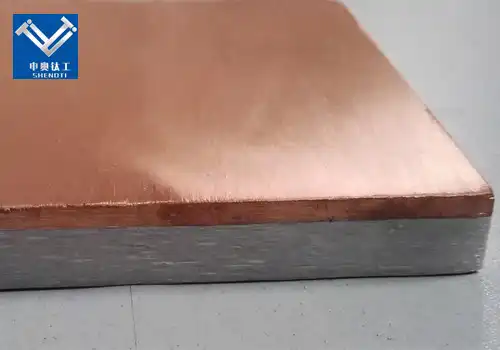

Manufacturing process of copper-aluminum bimetallic gaskets

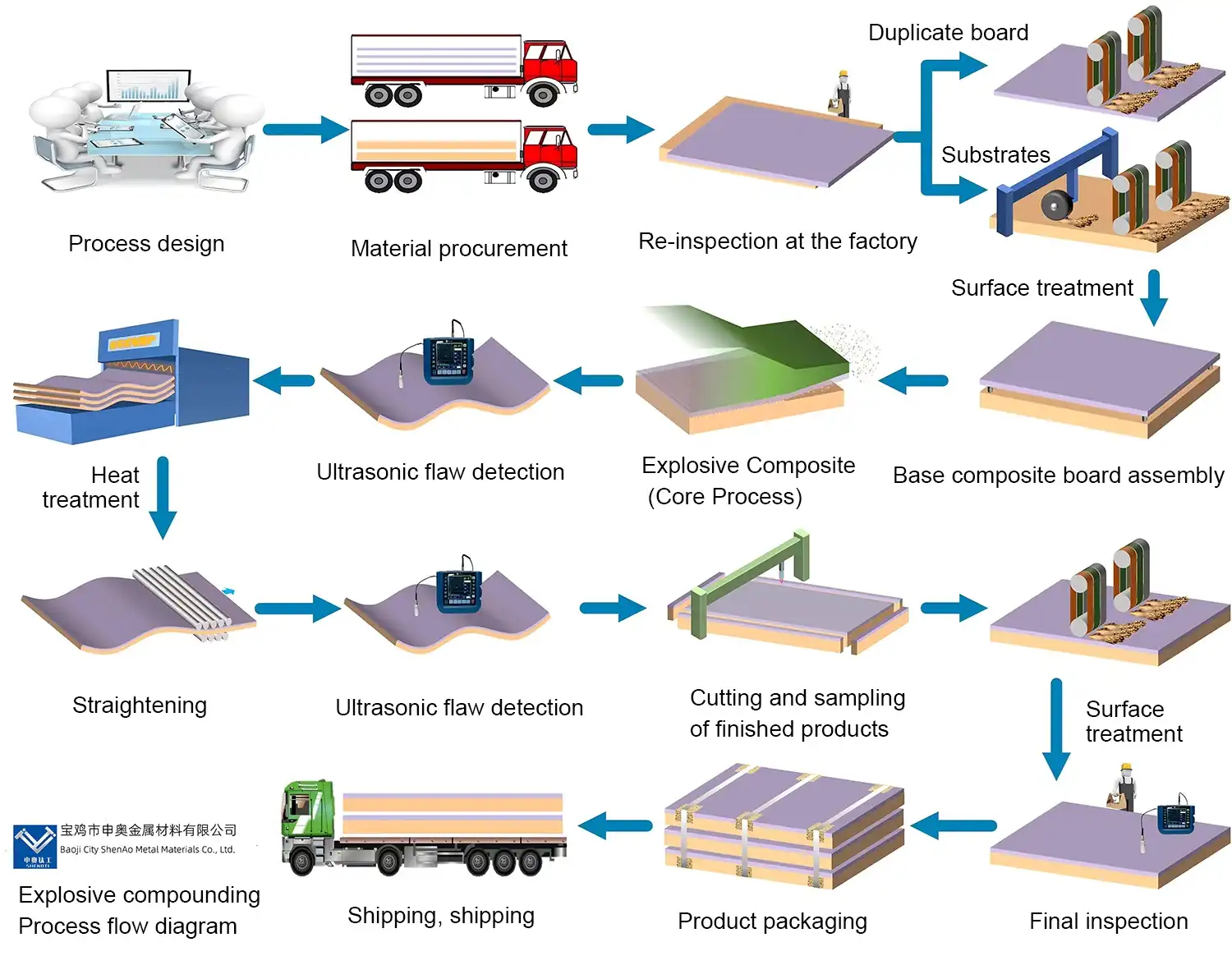

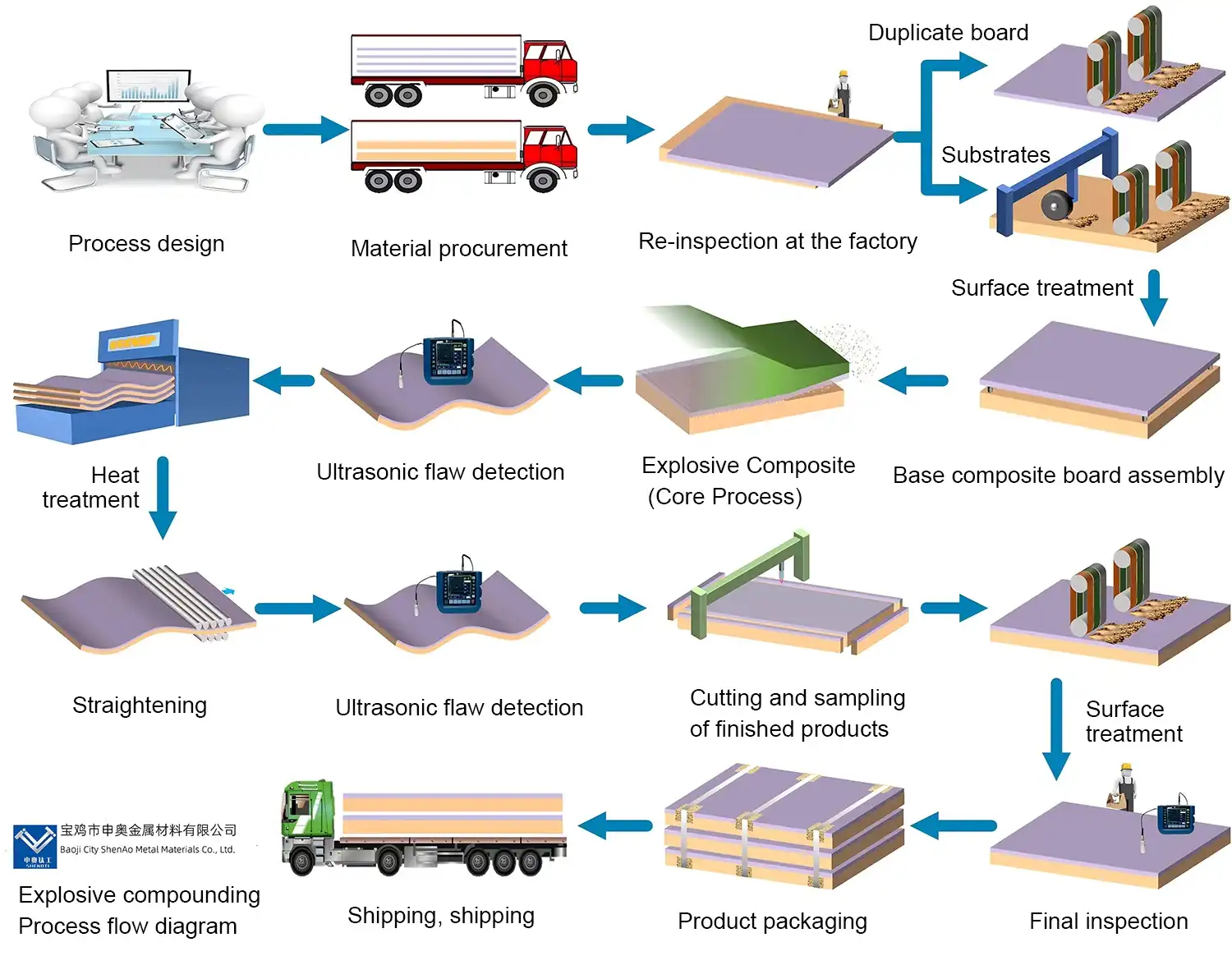

1. Explosive welding technology

Explosive welding is a process that uses the instantaneous impact force of explosives to achieve metallurgical bonding of two metal materials under high pressure conditions. It is suitable for high-strength connections between different metals. The interface formed by explosive welding has high bonding strength, no pores, and no inclusions, which is suitable for the preparation of high-demand copper-aluminum bimetallic gaskets.

2. Rolling composite method

Rolling composite is to mechanically composite copper and aluminum materials through multiple rolling processes at high temperature, and promote interface atomic diffusion through pressure and temperature to form a strong bond. This method is suitable for large-scale, cost-controlled gasket production, and is suitable for subsequent machining and stamping.

|

|

|

|

|

|

Advantages of copper-aluminum bimetallic gaskets

1. Excellent electrical and thermal conductivityThe addition of the copper layer makes the gasket have good electrical conductivity, which is particularly suitable for electrical sealing occasions such as grounding systems, power connectors, and transformer flanges. At the same time, the high thermal conductivity of copper also helps to disperse thermal stress in high temperature environments and reduce the risk of local heat concentration.

2. Good corrosion resistance

A dense oxide film is easily formed on the surface of the aluminum layer, which effectively prevents corrosion by corrosive media. Compared with pure copper gaskets, copper-aluminum bimetallic gaskets have a longer service life under harsh working conditions such as acid, alkaline and salt spray.

3. Lightweight materials

The density of aluminum is much lower than that of copper. The use of copper-aluminum composite form can significantly reduce the overall weight of the gasket, which has great advantages for weight-sensitive industries such as ships, aviation, and rail transportation.

4. Cost control advantage

Compared with all-copper or high-alloy sealing gaskets, copper-aluminum bimetallic gaskets reduce the cost of raw materials while ensuring performance, and are an ideal choice with both cost-effectiveness and performance balance.

Application fields of copper-aluminum bimetallic gaskets

1. Petroleum and chemical industryIn petrochemical equipment, the flange connection parts have extremely high requirements for the corrosion resistance and pressure resistance of the sealing gaskets. Copper-aluminum bimetallic gaskets are suitable for high temperature and high pressure environments such as heat exchangers, reactors, and pressure pipes due to their good composite strength and sealing performance.

2. Power equipment and cable connection

In transformer joints, cable connection plates, and high-voltage distribution cabinets, copper-aluminum bimetallic gaskets can effectively avoid electrochemical corrosion caused by contact between dissimilar metals, and improve the stability and service life of the contacts.

3. Shipbuilding and marine engineering

Copper-aluminum bimetallic gaskets have good seawater corrosion resistance and lightweight characteristics, and are often used in ship flanges, submarine hulls, and pipeline sealing devices for offshore platforms.

4. Military and aerospace

In military equipment, missile shells, aircraft engines and other high reliability requirements, copper-aluminum bimetallic gaskets provide a comprehensive solution with multiple functions such as sealing, conductivity, and weight reduction.

|

|

|

|

|

|

|

Product production process

Why Choose Us

1. Research and Innovation

At Baoji City ShenAo Metal Materials Co., Ltd., we pride ourselves on our professional technical R&D team. We continuously explore new applications and processes, ensuring our products remain at the forefront of industry advancements.

2. Excellent Reputation

With 17 years of experience, our commitment to quality and service has earned us the trust of customers worldwide. Our brand is synonymous with reliability and excellence.

3. Striving for Excellence

Our stringent quality control processes and comprehensive management systems ensure every product meets industry standards. From small batch testing to large-scale production, we deliver with precision and consistency.

4. Customized Services

We provide tailored solutions for various specifications, meeting the diverse requirements of our clients. Our expertise in non-ferrous metal composites and titanium anodes ensures unparalleled flexibility and satisfaction.

5. Timely Delivery and After-Sales Support

Our efficient logistics and customer-centric service guarantee prompt delivery and reliable after-sales assistance, giving you peace of mind.

6. OEM Services

We offer comprehensive OEM services, delivering products that align perfectly with your brand’s needs and expectations.

|

|

|

|

|

|

|

Product production process

Frequently Asked Questions (FAQs)

1. What is the lifespan of a Copper Aluminum Bimetallic Gasket?

The lifespan depends on the application and environment but generally exceeds 10 years in standard operating conditions.

2. Can the gasket be customized for unique applications?

Yes, we offer complete customization for size, shape, and material composition to meet your specific needs.

3. Is this product suitable for high-pressure applications?

Absolutely. The gasket can withstand pressures up to 500 MPa, making it ideal for demanding industrial uses.

Contact Us

For inquiries or to place an order, please contact us:

Name: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

We look forward to providing you with the most professional service and innovative solutions.