High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

Explosion Bonding Copper Clad Aluminum Product Page

Product Introduction

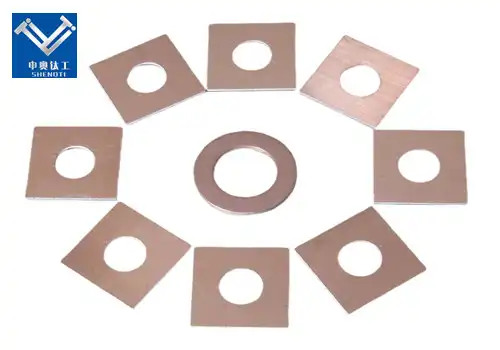

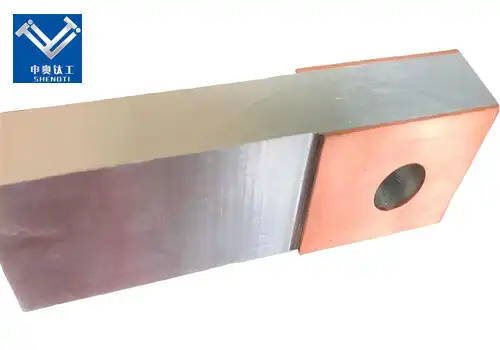

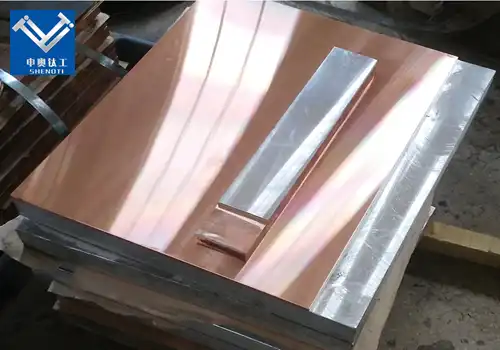

Explosion Bonding Copper Clad Aluminum is a high-performance composite material combining the excellent conductivity of copper with the lightweight and corrosion resistance of aluminum. This innovative product is manufactured using advanced explosive welding techniques, creating a strong metallurgical bond between the two metals. Widely used in industries such as electronics, power, marine, and environmental protection, Explosion Bonding Copper Clad Aluminum offers unmatched versatility and performance.

Technical Specifications

| Property | Value |

|---|---|

| Bonding Method | Explosive Welding |

| Thickness Ratio | Customizable (e.g., 10:90, 20:80) |

| Electrical Conductivity | Copper Layer: >97% IACS |

| Tensile Strength | >200 MPa |

| Corrosion Resistance | Excellent (both in air and seawater) |

| Operating Temperature Range | -40°C to 200°C |

| Plate Dimensions | 2000mm x 1000mm |

| Certification | ISO 9001, ASTM Standards |

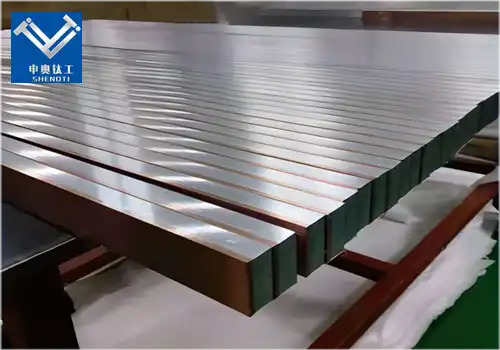

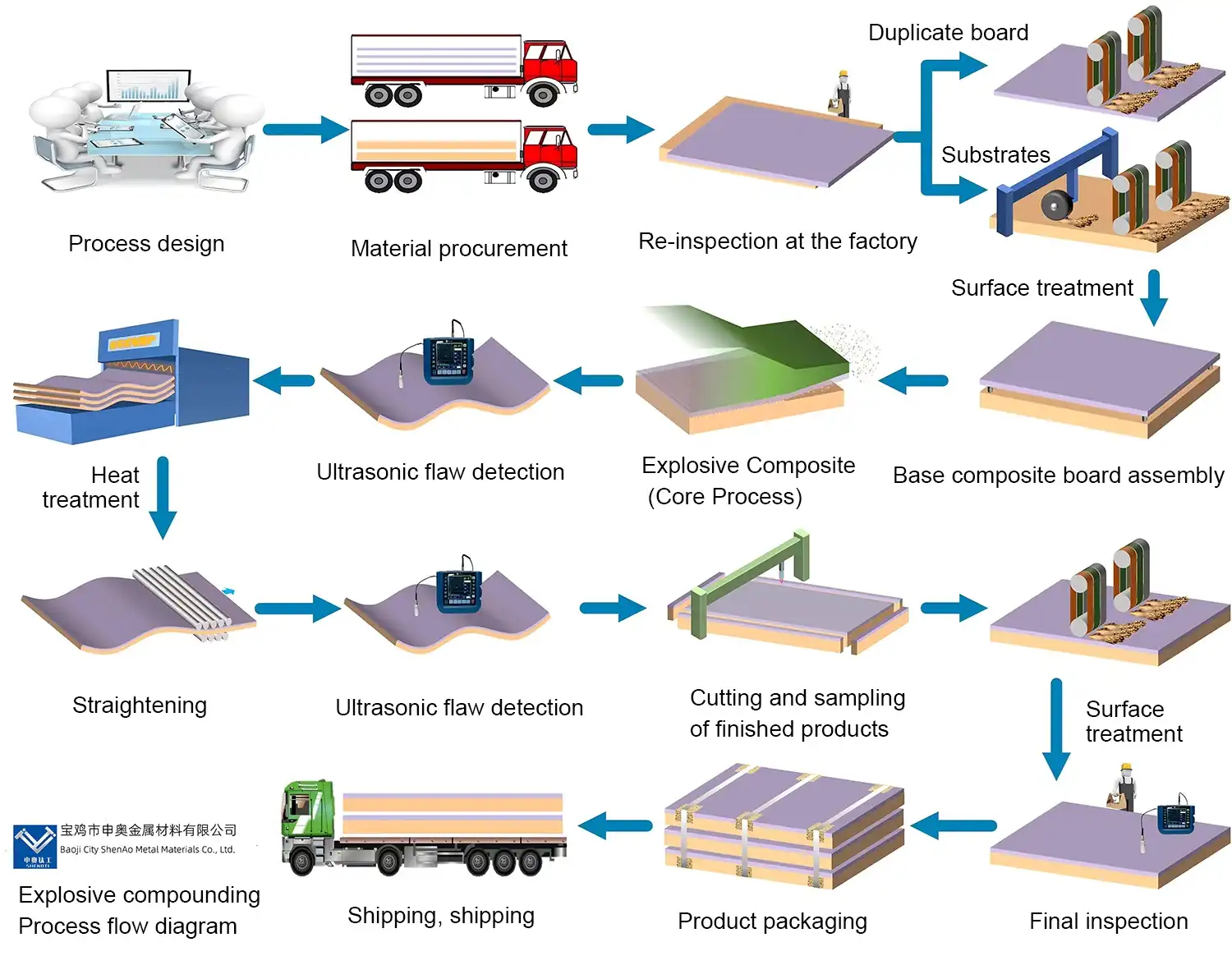

Manufacturing process of explosive copper composite aluminum plate

1. Material pretreatment

To ensure the cleanness of the composite interface and the firm bonding, the copper plate and the aluminum plate need to be strictly pretreated, such as surface deoxidation, degreasing, mechanical polishing and other processes to improve the contact activity between the metals.

2. Process parameter control

The manufacturing of explosive copper composite aluminum plate depends on the precise design of explosion parameters, including the type of explosives, charge density, the spacing between the flying plate and the bottom plate, the composite angle, etc. Different parameters will directly affect the propagation speed of the explosion wave, the interface morphology and the bonding strength.

3. Subsequent heat treatment and leveling

Some products need to be heat treated or vacuum annealed to improve the residual stress after the composite and enhance the uniformity of the organization. Through rolling, leveling and other processes, the target size accuracy and plate surface flatness can also be achieved.

|

|

|

|

|

|

Advantages of Explosive Copper Composite Aluminum Plate

1. Highly complementary material properties

Explosive copper composite aluminum plate combines the advantages of copper's high electrical conductivity and high thermal conductivity with aluminum's light weight, high plasticity, and good corrosion resistance. In application scenarios such as electrical engineering, heat exchanger manufacturing, and hot pressing molds, this composite material not only has excellent performance, but also effectively reduces costs.

Function of copper layer: Provides conductivity and wear resistance;

Function of aluminum base: Reduces material density and improves cost performance.

2. High-strength metallurgical bonding interface

Compared with traditional mechanical connection or brazing process, explosive copper composite aluminum plate forms a wavy interface through instantaneous ultra-high pressure impact, effectively avoiding the formation of brittle intermediate layers between metals, and has extremely high shear strength and anti-peeling ability. According to tests, its interface bonding strength usually exceeds the yield limit of the material itself.

3. Good processing performance

While having a high-strength bonding interface, the explosive copper composite aluminum plate still maintains good ductility and processability, and can be subjected to a variety of secondary processing processes such as shearing, stamping, bending, and deep drawing to meet the manufacturing needs of components of different shapes and structures.

Application fields of explosive copper composite aluminum plate

1. Electrical conductor manufacturing

The electrical conductivity of copper is nearly twice that of aluminum, but its cost is much higher than that of aluminum. By using explosive copper composite aluminum plate, the cost of raw materials can be greatly reduced while maintaining excellent electrical conductivity. It is often used to manufacture high-current busbars, transformer conductive terminals, cable connectors and other products.

2. Heat exchange equipment industry

Explosive copper composite aluminum plate is widely used in the manufacture of condensers, heat exchangers and other equipment. The copper layer can quickly conduct heat, while the lightweight characteristics of aluminum reduce the weight of the entire equipment, which is very suitable for occasions with high requirements for heat exchange efficiency and structural strength.

3. Metal structural parts

In aerospace and high-end machinery manufacturing, explosive copper composite aluminum plate can be used to manufacture lightweight and high-strength structural parts, especially in electromagnetic shielding, vacuum cavity, electrical connection panel and other fields. Its interface stability and corrosion resistance ensure the reliability of long-term service.

Quality inspection standards for explosive copper composite aluminum plates

Common inspection items

Interface bonding rate (must reach ≥98%)

Shear strength and peel strength (in accordance with GB/T 8547, ASTM B898 standards)

Metallographic analysis (no cracks, no inclusions, no voids)

Conductive performance test

Surface flatness and thickness tolerance

Advanced inspection methods

Ultrasonic flaw detection, electron microscope scanning, mechanical testing machine and other precision equipment are often used to conduct all-round inspections on explosive copper composite aluminum plates to ensure that their structure and performance meet high-end application requirements

|

|

|

|

|

|

|

Product production process

Why Choose Us

Research and Innovation

Baoji City ShenAo Metal Materials Co., Ltd. boasts a professional research and development team dedicated to exploring new processes and applications. Our commitment to innovation ensures we stay ahead in the industry, delivering cutting-edge products to our clients.

Excellent Reputation

With over 17 years of experience, we have built a strong reputation for delivering quality products and reliable customer service. Our brand is trusted by clients worldwide.

Striving for Excellence

Our strict production processes and comprehensive quality management system guarantee consistent quality. Whether for small batch testing or large-scale production, we ensure timely delivery and product stability.

Customized Services

We provide tailored solutions for various specifications of Explosion Bonding Copper Clad Aluminum to meet diverse customer requirements.

Timely Delivery and After-Sales Support

We prioritize our customers with timely delivery and exceptional after-sales service, ensuring satisfaction and long-term partnerships.

OEM Services

We offer original equipment manufacturing services to cater to your unique product needs, maintaining high quality and confidentiality.

FAQs

1. What is the minimum order quantity (MOQ)? The MOQ varies depending on the product specifications. Please contact us for more details.

2. Can you provide customized thickness ratios? Yes, we can customize the thickness ratio according to your specific requirements.

3. What is the typical lead time for delivery? The lead time depends on the order quantity and specifications. Generally, it ranges from 4 to 6 weeks.

4. How do you ensure product quality? We adhere to strict quality control standards, including ISO 9001 certification and rigorous in-house testing.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Contact Us

We are here to provide the most professional service. Please contact us for your Explosion Bonding Copper Clad Aluminum needs.

-

Company Name: Baoji City ShenAo Metal Materials Co., Ltd

-

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

-

Contact: Wang Shujuan

-

Phone: +86 18729731603

-

Fax: +86 917-3380538

-

Email: zh@baojiti.com.cn

Experience the excellence of Explosion Bonding Copper Clad Aluminum by partnering with Baoji City ShenAo Metal Materials Co., Ltd. Let us help you achieve superior performance and reliability in your applications.