High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

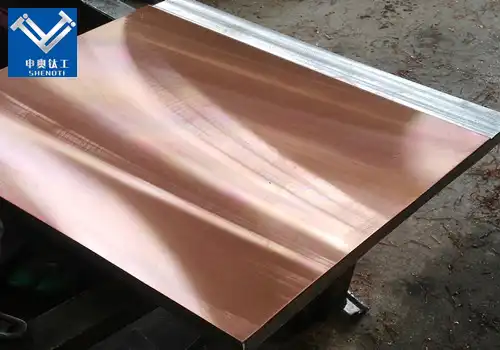

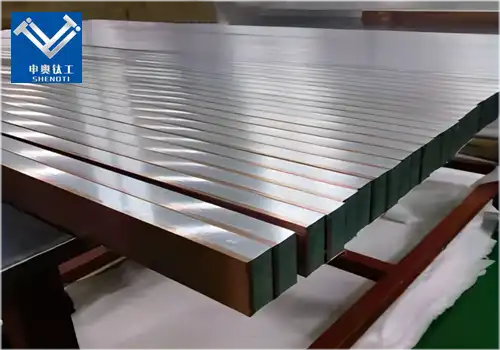

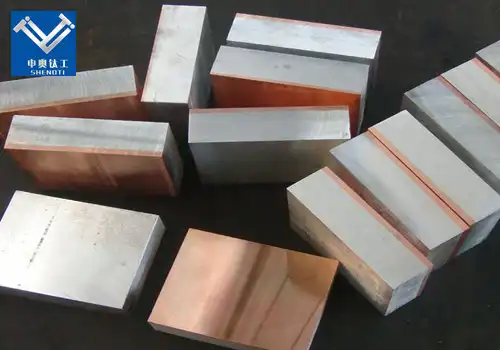

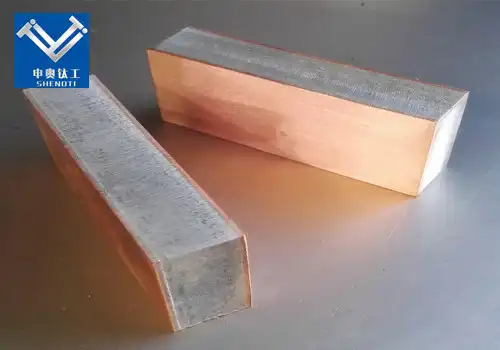

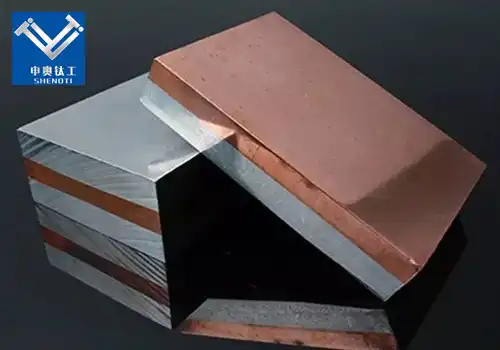

10mm ccopper aluminum transition plate is a composite material formed by firmly combining copper layer and aluminum layer through a specific metallurgical bonding process, with an overall thickness of 10mm. According to actual needs, the ratio of copper to aluminum can be flexibly configured, such as copper 2mm + aluminum 8mm, or copper 3mm + aluminum 7mm, etc.

As a typical metal composite product, 10mm copper aluminum transition plate has excellent electrical conductivity, thermal conductivity and mechanical properties, and has received widespread attention and application in many fields such as electricity, electronics, rail transportation, and new energy.

copper aluminum transition plate production method:

Explosive welding (explosive composite): copper and aluminum are instantly metallurgically bonded through high-energy explosion, and the interface bonding strength is high.

Rolling composite: two metals are laminated and formed through multiple rolling passes under high temperature conditions.

Explosive rolling composite: two metal plates are explosively bonded + rolled to achieve the required thickness.

|

|

|

|

|

|

Main performance characteristics of 10mm copper aluminum transition plate

1. Excellent electrical and thermal conductivityThe copper layer has extremely high electrical conductivity (about 58MS/m) and thermal conductivity (about 390W/m·K), combined with the good thermal diffusion performance of aluminum, so that 10mm copper composite aluminum plate is widely used in heat dissipation systems, power busbars, electrode materials and other fields.

2. Weight reduction and light structure

Compared with pure copper plates of the same thickness, 10mm copper composite aluminum plate can effectively reduce the structural weight by 30%~50%, significantly reduce the equipment load without sacrificing electrical conductivity, and improve system efficiency.

3. Strong combination and stable performance

Metallurgical processes such as explosive composite or hot rolling diffusion are used to ensure that there are no obvious inclusions, voids or oxide layers on the copper-aluminum bonding surface, and the shear strength is higher than 130MPa, which can withstand high loads and thermal cycles for a long time.

4. Good processing formability

10mm copper composite aluminum plate can be subjected to conventional mechanical processing such as shearing, stamping, bending, welding, etc., and is suitable for various electrical assembly or structural parts manufacturing.

Application fields of 10mm copper aluminum transition plate

1. Power equipment and busbar system

In systems such as high-voltage busbars, grounding bars, and distribution cabinets, the copper layer provides a good conductive path, and the aluminum layer reduces the overall mass, saves material costs and improves thermal stability. It is widely used in projects such as the national power grid and new energy power distribution.

2. Communications and electronics

10mm copper-clad aluminum plate is used to manufacture heat dissipation substrates, EMI shielding structural parts, signal connectors, etc., to improve thermal management and electromagnetic compatibility performance. It is a material in 5G communication base stations and new energy vehicle control systems.

3. Rail transit and rail electrification

Rail transit equipment requires that the conductive structure must be both highly conductive and lightweight. 10mm copper-clad aluminum plate can be used for structures such as pantograph slides, electrical connection conductors, and high-speed train signal interfaces, taking into account lightweight and high current carrying requirements.

4. Aerospace and military equipment

In aerospace, composite materials have higher requirements for lightness and multi-function. Copper-clad aluminum plate can realize the integrated design of electromagnetic shielding, thermal conductivity and heat dissipation, and corrosion resistance of structural parts, and improve the comprehensive performance of aircraft systems.

|

|

|

|

|

|

|

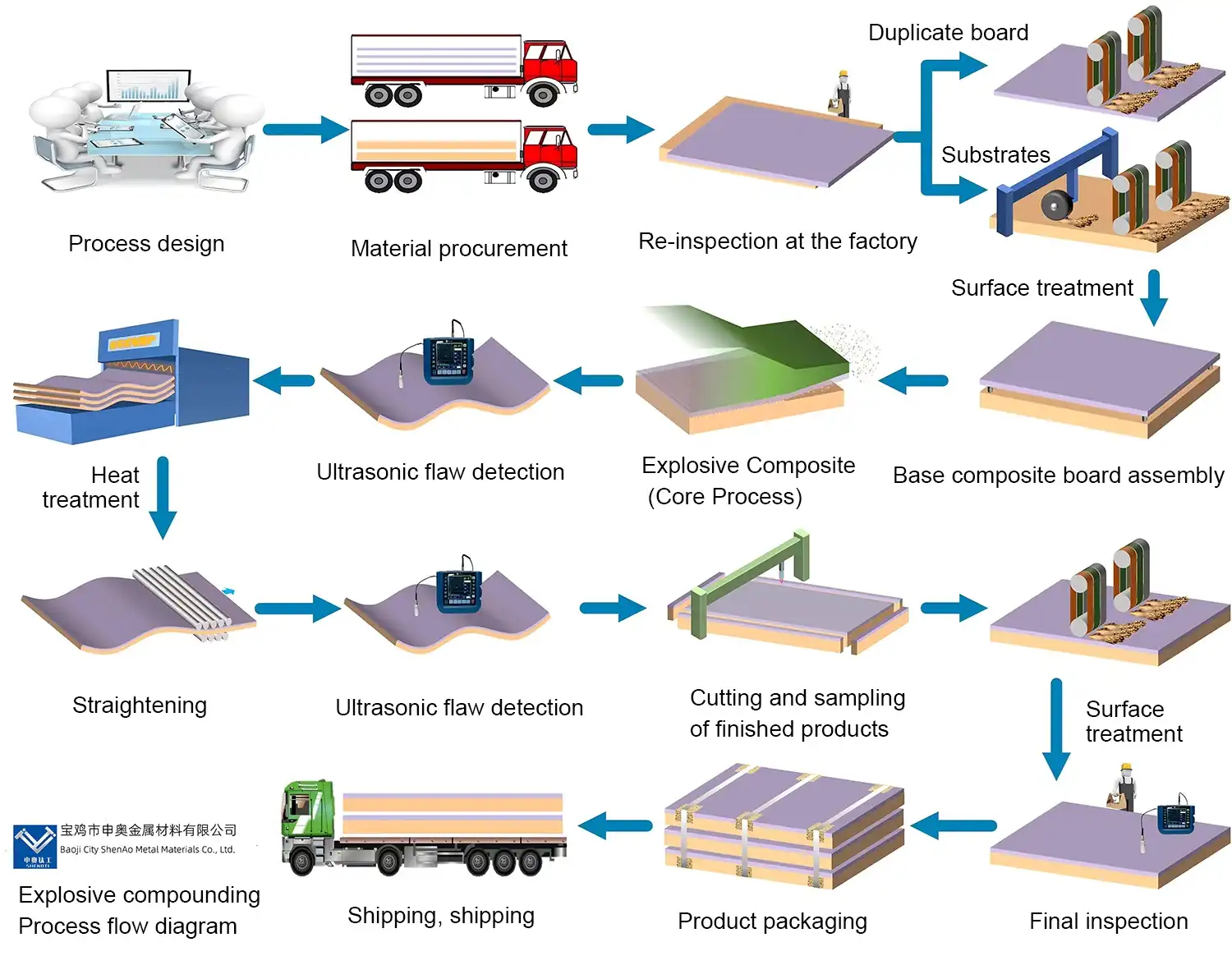

Product production process

Why Choose Us

1. Research and Innovation

At Baoji City ShenAo Metal Materials Co., Ltd., our experienced R&D team continuously explores new technologies and applications to drive product innovation and meet customer demands.

2. Excellent Reputation

With 17 years of expertise, we have established a strong reputation for quality and reliability. Our brand is trusted worldwide for its superior products and customer service.

3. Striving for Excellence

Our commitment to excellence is evident in our strict production processes and comprehensive quality management system, ensuring every product meets high standards. We excel in both small batch production and large-scale manufacturing.

4. Customized Product Services

We offer tailored solutions to meet diverse customer needs, including various specifications and applications. Our expertise ensures precise and effective results.

5. Timely Delivery and Reliable After-Sales Support

Customer satisfaction is our priority. We ensure prompt delivery and provide exceptional support to address any concerns.

6. OEM Services

We collaborate with clients to deliver bespoke OEM solutions, leveraging our expertise in composite materials.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is the primary advantage of using copper clad aluminum? A: CCA offers high conductivity, lightweight properties, and cost savings, making it a versatile and economical choice for various industries.

Q2: Is copper clad aluminum corrosion-resistant? A: Yes, it exhibits excellent corrosion resistance, especially in marine and industrial environments.

Q3: Can specifications be customized? A: Absolutely. We provide tailored solutions to meet specific technical and application requirements.

Q4: What industries benefit most from CCA? A: Industries such as electrical equipment, telecommunications, automotive, and marine benefit significantly from using CCA.

Contact Details

For inquiries or additional information, please reach out to us:

Baoji City ShenAo Metal Materials Co., Ltd

-

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

-

Contact: Wang Shujuan

-

Phone: +86-18729731603

-

Fax: +86-917-3380538

-

Email: zh@baojiti.com.cn

Let us help you find the perfect copper clad aluminum solution for your needs. Reach out today to learn more about our products and services.