Bimetallic Aluminum DT4 Clad Plate Manufacturing Process

2025-04-16T16:00:00.000Z

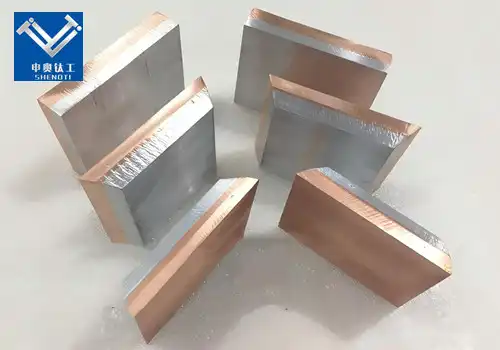

In the realm of advanced materials, bimetallic clad plates have emerged as a revolutionary solution, combining the advantageous properties of two distinct metals into a single, cohesive unit. Among these, the bimetallic aluminum DT4 clad plate stands out for its unique combination of aluminum and DT4 steel, offering a blend of lightweight characteristics, excellent corrosion resistance, and superior magnetic properties.

What Is a Bimetallic Aluminum DT4 Clad Plate?

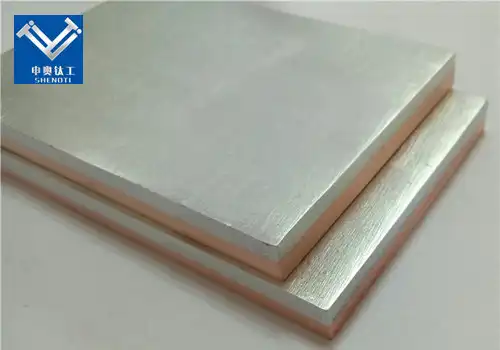

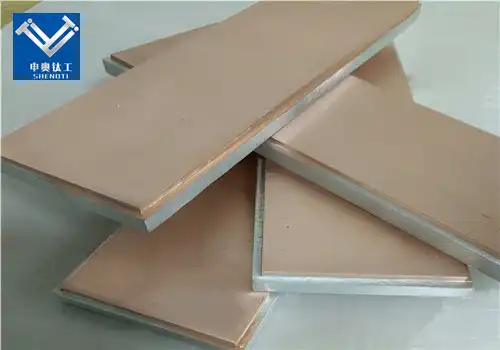

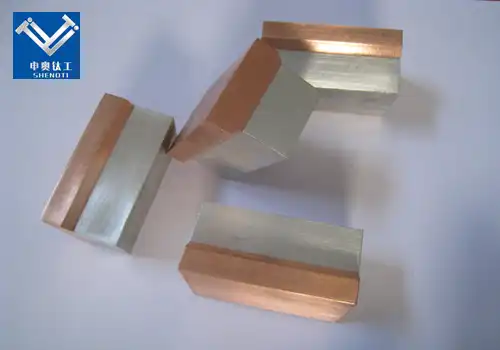

A bimetallic aluminum DT4 clad plate is a composite material consisting of two distinct layers: an outer layer of aluminum and an inner layer of DT4 steel. The aluminum layer provides excellent corrosion resistance and thermal conductivity, while the DT4 steel layer offers superior magnetic properties and mechanical strength. This combination results in a material that leverages the benefits of both metals, making it suitable for applications requiring both electrical conductivity and magnetic performance.

Composition and Structure

Aluminum Layer: Typically made from high-purity aluminum, this layer offers excellent corrosion resistance, lightweight characteristics, and high thermal and electrical conductivity.

DT4 Steel Layer: DT4 is a type of pure iron with high magnetic permeability and low coercivity, making it ideal for electromagnetic applications. It provides the necessary magnetic properties and structural strength to the clad plate.

Manufacturing Process

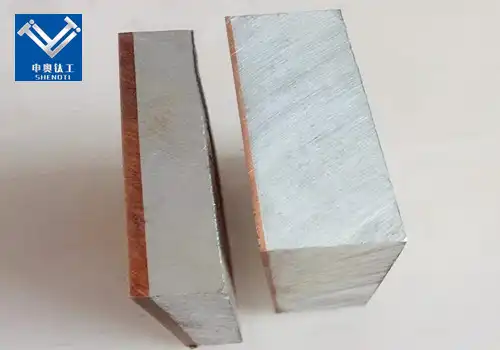

The production of bimetallic aluminum DT4 clad plates involves advanced bonding techniques to ensure a strong metallurgical bond between the two layers. The primary methods include:

Explosion Bonding: This process involves placing the aluminum and DT4 steel plates together and subjecting them to a controlled explosive force. The high-pressure impact causes a metallurgical bond without melting the materials, preserving their individual properties.

Roll Bonding: In this method, the aluminum and DT4 steel plates are cleaned, stacked, and passed through high-pressure rollers. The pressure and heat generated during rolling create a solid-state bond between the layers.

Explosion-Roll Bonding: This hybrid technique combines explosion bonding and roll bonding to achieve a more uniform bond and improved mechanical properties. Initially, explosion bonding creates the primary bond, followed by roll bonding to enhance the bond's uniformity and surface finish.

What Are the Advantages of Aluminum Clad Plates?

Aluminum clad plates, including bimetallic aluminum DT4 clad plates, offer a multitude of advantages that make them highly desirable in various industrial applications:

1. Corrosion Resistance

The aluminum layer provides excellent resistance to corrosion, especially in harsh environments. This property extends the lifespan of the clad plate and reduces maintenance costs.

2. Lightweight

Aluminum's low density contributes to the overall lightweight nature of the clad plate, making it easier to handle and reducing the structural load in applications such as construction and transportation.

3. Thermal and Electrical Conductivity

Aluminum's high thermal and electrical conductivity makes the clad plate suitable for applications requiring efficient heat dissipation and electrical performance.

4. Magnetic Properties

The DT4 steel layer imparts excellent magnetic properties, essential for electromagnetic applications like transformers and electric motors.

5. Mechanical Strength

The combination of aluminum and DT4 steel results in a material with superior mechanical strength, capable of withstanding significant stress and strain.

6. Cost-Effectiveness

By combining two metals, clad plates can achieve desired properties at a lower cost compared to using a single, more expensive material throughout.

How Is Aluminum Clad Plate Manufactured?

The manufacturing of aluminum clad plates involves meticulous processes to ensure a strong bond between the aluminum and the base metal, such as DT4 steel. The primary manufacturing methods include:

1. Explosion Bonding

This technique uses controlled explosive energy to bond the aluminum and steel layers. The process involves:

Americlad

Cleaning and preparing the metal surfaces.

Aligning the plates with a specific standoff distance.

Detonating explosives to generate a high-pressure wave that bonds the metals.

Explosion bonding creates a strong metallurgical bond without melting the materials, preserving their individual properties.

2. Roll Bonding

In roll bonding, the aluminum and steel sheets are cleaned, stacked, and passed through rollers under high pressure and temperature. This process causes plastic deformation and diffusion at the interface, resulting in a solid-state bond.

3. Explosion-Roll Bonding

Aluminum DT4 clad plates are used in building facades, roofing, and structural components, offering durability, corrosion resistance, and aesthetic appeal.

4. Aerospace Industry

The lightweight and high-strength characteristics make these clad plates suitable for aircraft components, contributing to fuel efficiency and performance.

Contact Us

For more information about bimetallic aluminum DT4 clad plates or to discuss your specific requirements, please contact us at:

Email: zh@baojiti.com.cn

YOU MAY LIKE