High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

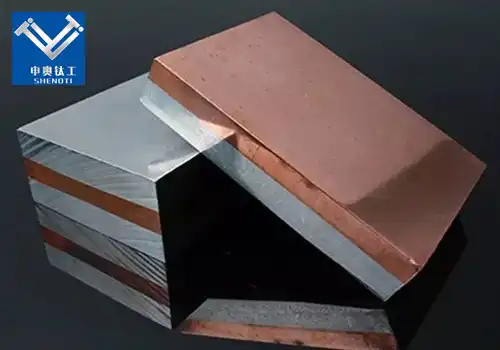

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

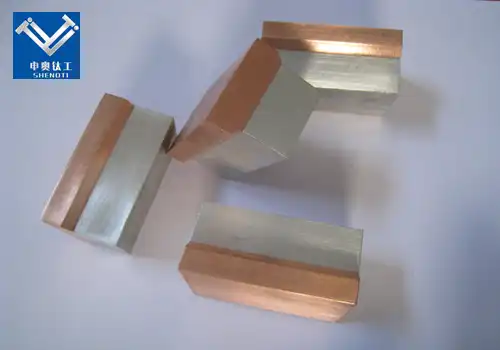

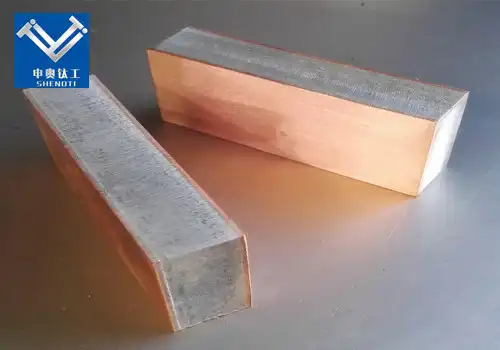

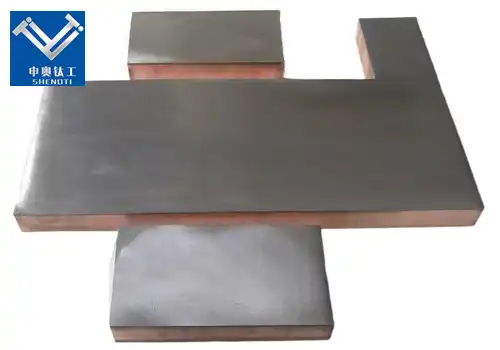

Copper Coated Metal Plate

Copper metal composite plate is a multi-layer metal composite material made of copper and one or more metals (such as aluminum, stainless steel, carbon steel, titanium, etc.) through metallurgical or mechanical methods. It combines the excellent electrical and thermal conductivity of copper with the strength, corrosion resistance or light weight of other metals to form a composite plate with comprehensive performance advantages.

Structural types of copper metal composite plates

Double-layer structure: such as copper-aluminum, copper-steel composite plates.

Three-layer structure: such as copper-aluminum-copper, copper-steel-copper and other composite plates.

Multi-layer composite structure: used for special material composites with more complex requirements.

Copper metal composite plates with different structures can be customized for different industrial applications, taking into account both functionality and economy.

Main manufacturing processes of copper metal composite plates

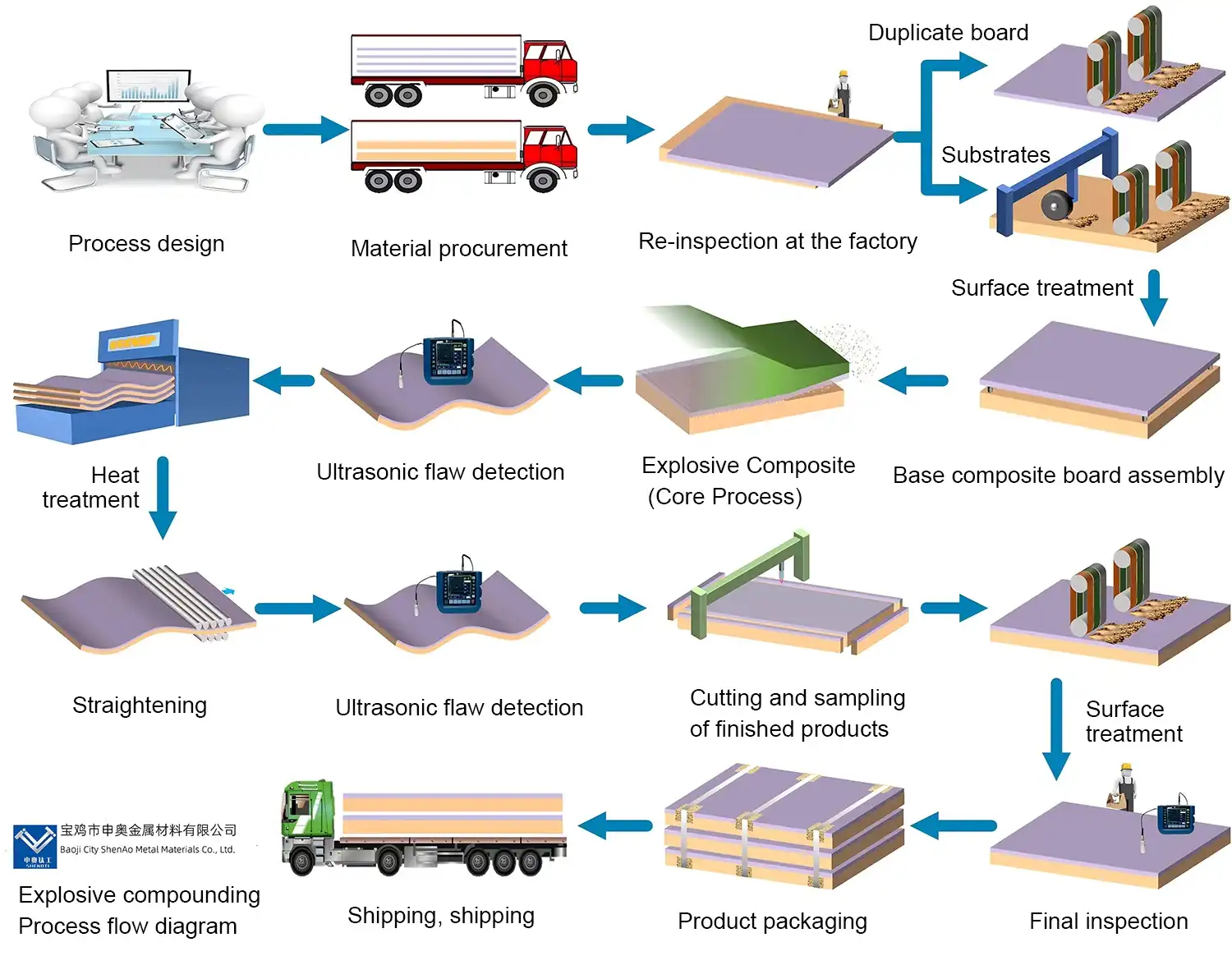

1. Explosive welding technology

Explosive welding is a high-energy physical connection technology commonly used in the production of copper metal composite plates. It uses the high temperature and high pressure generated by the explosion of explosives to achieve metallurgical bonding of two metals within nanoseconds. This method can overcome the problem of large differences in material melting points in traditional welding, and is particularly suitable for the composite of copper with steel, stainless steel and other metals.

2. Hot rolling composite technology

Hot rolling composite is a method of combining copper plates with other metal plates by rolling at high temperatures. The process has a stable bonding effect and is suitable for large-scale continuous production.

3. Explosive + rolling composite process

The most advanced composite method at present is the "explosive + rolling" combined process. First, the initial bonding is achieved through explosion, and then the strength and uniformity of the bonding interface are further improved through hot rolling or cold rolling to ensure the stability and safety of the copper metal composite plate during use.

Technical Specifications

| Parameter | Value |

|---|---|

| Composition | Copper + Aluminum/Steel/Titanium |

| Thickness | 0.5mm to 100mm (customizable) |

| Width | 1000mm (customizable) |

| Length | 2000mm (customizable) |

| Copper Coating Thickness | 0.5mm to 2mm |

| Tensile Strength | ≥400 MPa |

| Yield Strength | ≥250 MPa |

| Electrical Conductivity | 60-65% IACS (International Annealed Copper Standard) |

| Corrosion Resistance | Excellent in marine and industrial environments |

| Density | 8.93 g/cm³ (for copper layer) |

| Surface Finish | Smooth, polished, or as required |

| Customization Options | Size, thickness, coating, and material combinations |

|

|

|

|

|

|

Performance characteristics of copper metal composite plate

1. Excellent electrical and thermal conductivity

The surface of the copper metal composite plate retains high-purity copper material, which has extremely high electrical conductivity and thermal conductivity. It is an ideal choice for making conductive busbars, radiators, copper-clad circuit boards and other products.

2. Good corrosion resistance and mechanical strength

By compounding with materials such as stainless steel and titanium alloy, the mechanical strength and corrosion resistance of the copper metal composite plate can be significantly improved, meeting the long-term use in harsh environments such as acid, alkali, and high temperature.

3. Save costs and improve cost performance

The price of copper is high, and the cost of directly using pure copper structures is high. The copper metal composite plate effectively reduces the material cost by compounding the copper layer with other low-cost structural metals, improving the overall economy while ensuring performance.

4. Strong machinability

The copper metal composite plate is suitable for a variety of processing methods such as shearing, stamping, and welding. It is suitable for the design and manufacture of different structural parts, and is convenient for subsequent mechanical processing and assembly.

Application fields of copper-metal composite plates

1. Electronics and power industry

Copper-metal composite plates are widely used in heat sinks of electronic devices, conductive busbars of power equipment, electromagnetic shielding materials, etc. Especially in new energy vehicles, 5G communication equipment and high-power modules, the demand for copper's thermal conductivity is increasing, which has promoted the rapid growth of the copper composite plate market.

2. Construction and decoration field

Copper's stainless, anti-oxidation and beautiful characteristics make it a representative of high-end building materials. By compounding with stainless steel and aluminum, copper-metal composite plates can be used in scenes such as curtain walls, exterior wall decoration, and interior panels, which not only meets the design aesthetics, but also takes into account structural strength and cost control.

3. Petrochemical equipment

In chemical equipment, copper can be used in the manufacture of equipment such as heat exchangers, reactors, and pressure vessels after being compounded with titanium and stainless steel, making full use of the thermal conductivity of copper and the structural advantages of other metals to improve the operating efficiency and service life of the device.

4. Environmental protection and new energy field

Copper-metal composite plates play an important role in emerging fields such as water treatment electrodes, new energy battery collectors, and photothermal conversion devices. For example, copper-aluminum composite plates have gradually replaced pure copper for lithium battery positive electrode current collectors, significantly reducing battery weight and cost.

|

|

|

|

|

|

|

Product production process

Why Choose Us: Our Advantages

1. Research and Innovation

Our R&D team is dedicated to exploring new technologies and improving the performance of our products. We continually innovate to meet the evolving needs of our customers and industry standards.

2. Excellent Reputation

With over 17 years of industry experience, Baoji City ShenAo Metal Materials Co., Ltd. has built a strong reputation for delivering high-quality products and exceptional customer service.

3. Striving for Excellence

Our commitment to producing products that adhere to the highest standards ensures that we can meet both small batch and large-scale production demands. Every product goes through a rigorous quality control process to guarantee reliability and performance.

4. Customized Product Services

We provide tailored solutions to meet specific customer needs. Whether you need customized specifications, materials, or coatings, we can deliver a product that meets your exact requirements.

5. Timely Delivery, Worry-Free After-Sales Service

We understand the importance of timely delivery and providing excellent after-sales support. Our team is always ready to assist with any concerns or inquiries.

6. OEM Services

We offer OEM services to accommodate unique specifications and requirements, ensuring a seamless integration of our copper-coated metal plates into your production line.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

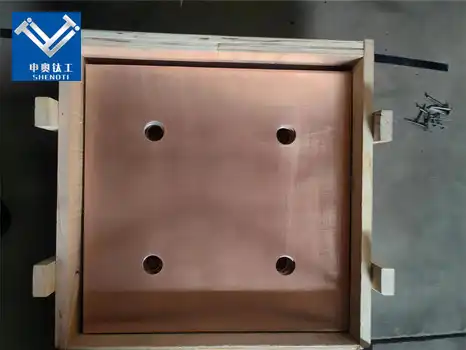

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q: What are copper-coated metal plates used for? A: Copper-coated metal plates are primarily used in electrical equipment, power transmission, chemical reactors, and marine industries due to their excellent conductivity and corrosion resistance.

Q: How can I customize copper-coated metal plates for my project? A: We offer customization options for size, thickness, and material combinations. Please contact us for specific requirements.

Q: How does the bimetal explosive welding process enhance product performance? A: This process ensures a strong bond between the copper and base metal, resulting in a durable, high-performance product that withstands extreme conditions.

Q: What is the delivery time for copper-coated metal plates? A: Delivery times depend on the size and complexity of the order. Typically, we deliver within 15 to 30 days, depending on the customization requirements.

Q: Can copper-coated metal plates be used in marine environments? A: Yes, the copper layer provides excellent resistance to corrosion, making our copper-coated metal plates ideal for marine applications.

Contact Details

We are here to provide you with the most professional service for your copper-coated metal plate needs.

Company Name: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86 18729731603

Fax: +86 917-3380538

Email: zh@baojiti.com.cn

Reach out to us for more information or to place an order. We are committed to delivering quality products and excellent service.

YOU MAY LIKE