What Is a Nickel Clad Plate and How Is It Manufactured?

2025-04-16T08:00:00.000Z

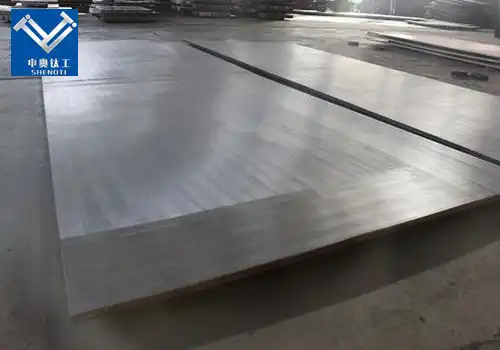

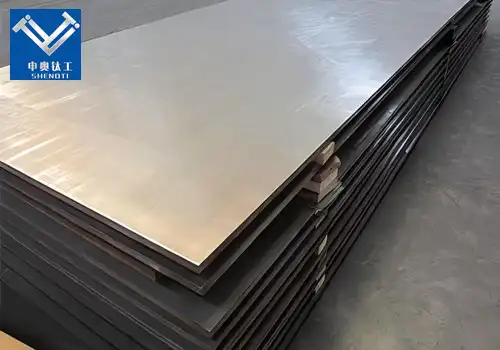

Nickel-based alloy composite plates, commonly known as Nickel Clad Plates, are engineered materials that combine the structural strength of a base metal, typically carbon or stainless steel, with the corrosion resistance and durability of a nickel alloy layer. This fusion results in a versatile material suitable for various demanding applications across multiple industries.

What Is a Nickel Clad Plate and How Is It Manufactured?

A Nickel Clad Plate is a composite material consisting of a base metal, such as carbon steel or stainless steel, bonded with a layer of nickel or nickel-based alloy. This combination leverages the mechanical strength of the base metal and the corrosion resistance of nickel.

Manufacturing Processes

Several methods are employed to manufacture Nickel Clad Plates, each with its advantages:

Explosion Bonding: This technique uses controlled explosive energy to bond the nickel layer to the base metal, resulting in a high-strength metallurgical bond without melting the materials.

Roll Bonding: In this process, the base metal and nickel alloy are heated and passed through rollers, causing them to bond under pressure.

Explosion-Roll Bonding: A hybrid method that combines explosion bonding and roll bonding to enhance bond strength and uniformity.

Each method ensures a durable bond between the layers, maintaining the integrity of the composite plate under various operational conditions.

Why Are Nickel Clad Plates Preferred in Corrosive Environments?

Superior Corrosion Resistance

Nickel and its alloys exhibit exceptional resistance to corrosion, especially in harsh environments involving acids, alkalis, and saline conditions. This makes Nickel Clad Plates ideal for industries such as chemical processing, marine engineering, and power generation.

Longevity and Maintenance

The corrosion-resistant properties of the nickel layer extend the service life of equipment and structures, reducing the need for frequent maintenance and replacements. This results in cost savings and improved operational efficiency.

How Do Nickel Clad Plates Compare to Other Cladding Materials?

Advantages Over Stainless Steel Cladding

While stainless steel cladding offers corrosion resistance, Nickel Clad Plates provide superior performance in more aggressive environments. Nickel alloys can withstand higher temperatures and more corrosive substances than standard stainless steels.

Cost-Effectiveness

Although nickel alloys are more expensive than some other materials, the extended lifespan and reduced maintenance requirements of Nickel Clad Plates often result in lower total ownership costs.

What Are the Common Applications of Nickel Clad Plates?

Chemical and Petrochemical Industries

Nickel Clad Plates are extensively used in the construction of reactors, heat exchangers, and storage tanks due to their ability to withstand corrosive chemicals and high temperatures.

Power Generation

In power plants, especially those utilizing fossil fuels or nuclear energy, these plates are used in components exposed to high temperatures and corrosive environments.

Marine Engineering

The marine industry benefits from Nickel Clad Plates in shipbuilding and offshore structures, where resistance to seawater corrosion is critical.

Aerospace and Defense

The aerospace sector utilizes these plates in components that require high strength-to-weight ratios and resistance to extreme environmental conditions.

Contact Us

For more information about Nickel Clad Plates and how they can benefit your specific applications, please contact us at:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with product selection, technical specifications, and any other inquiries you may have.