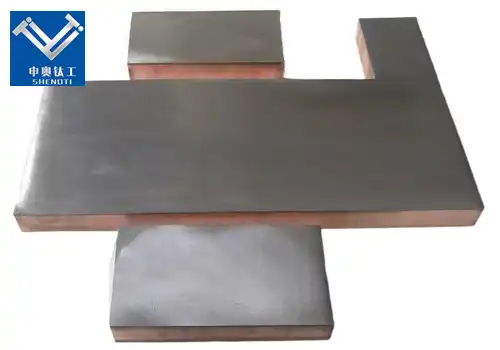

High conductivity Inheriting the excellent conductive properties of copper

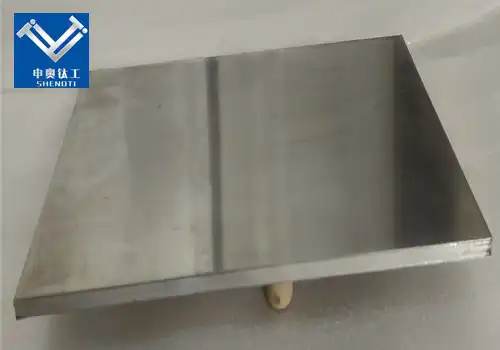

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

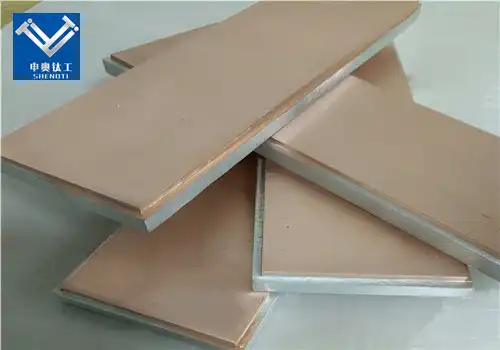

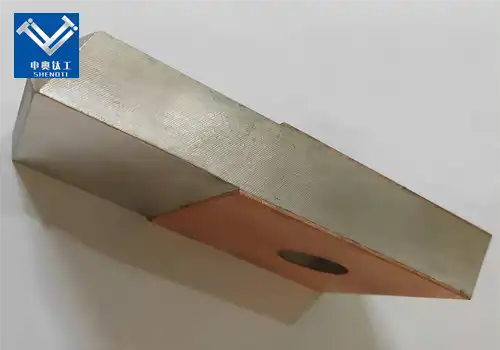

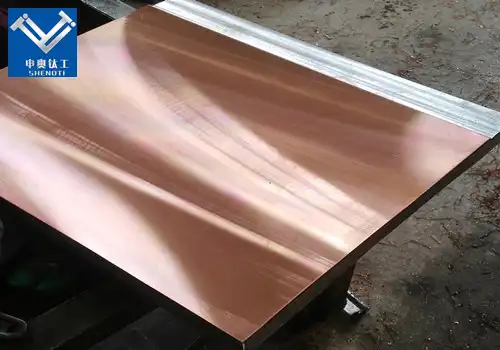

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

Metal cladding sheets have become a critical material in today’s construction, industrial manufacturing, energy, and transportation sectors. They combine durability, functionality, and aesthetics, providing an innovative solution for projects that require protection, performance, and cost efficiency. Whether used in building facades, pressure vessels, chemical equipment, or new energy systems, metal cladding sheets deliver unmatched advantages.

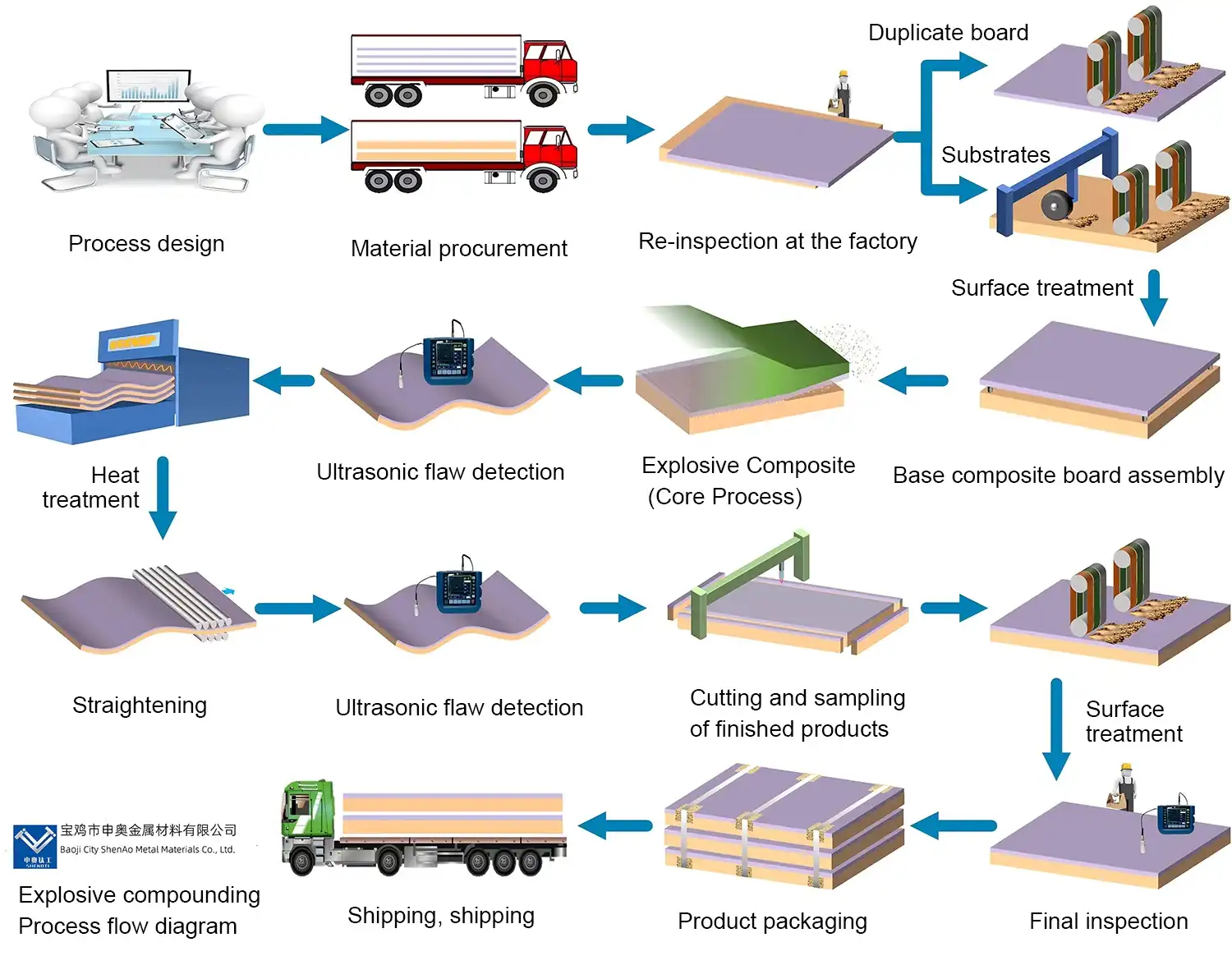

Manufacturing Processes of Metal Cladding Sheets

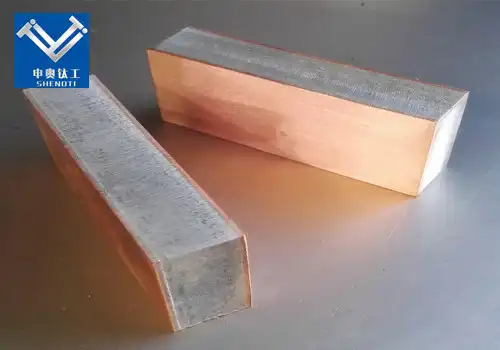

1. Explosion Welding

Explosion welding is one of the most widely used processes for producing metal cladding sheets. By using controlled detonation energy, two dissimilar metals are bonded at high velocity, creating a wavy metallurgical interface.

Advantages: Excellent bond strength, ability to join metals that are otherwise impossible to weld, large sheet sizes available.

Applications: Copper-clad aluminum sheets, stainless steel-clad steel plates, titanium-clad steel plates.

2. Hot Rolling and Cold Rolling

Rolling processes involve passing layered metals through rollers under high pressure.

Hot Rolling: Performed at high temperatures, improves ductility and grain structure.

Cold Rolling: Carried out at room temperature, enhancing surface finish and dimensional accuracy.

Technical Specifications

| Property | Copper-Aluminum Clad Plate | Copper-Steel Clad Plate | Titanium-Copper Clad Plate | Nickel-Steel Clad Plate |

|---|---|---|---|---|

| Thickness | 1mm - 100mm | 1mm - 100mm | 1mm - 100mm | 1mm - 100mm |

| Cladding Material | Copper/Aluminum | Copper/Steel | Titanium/Copper | Nickel/Steel |

| Electrical Conductivity (IACS) | ≥ 65% | ≥ 60% | ≥ 45% | ≥ 50% |

| Tensile Strength | ≥ 250 MPa | ≥ 300 MPa | ≥ 350 MPa | ≥ 400 MPa |

| Corrosion Resistance | Excellent in seawater | Excellent in chemical environments | Excellent in high-temperature applications | Excellent in industrial and marine environments |

| Temperature Resistance | ≤ 250°C | ≤ 500°C | ≤ 600°C | ≤ 450°C |

| Surface Finish | polished | polished | polished | polished |

| Applications | Seawater desalination, chemical equipment, power transmission | Power transmission, heavy industry, electrical equipment | Marine applications, electrochemical processes, energy production | Electrochemical applications, wastewater treatment |

|

|

|

|

|

|

Key Advantages of Metal Cladding Panels

- Corrosion Resistance: Stainless steel, titanium, and nickel claddings protect against acidic or marine environments.

- Cost Efficiency: Expensive metals like titanium or copper are only used as surface layers, reducing total costs.

- Mechanical Strength: Steel substrates provide rigidity and impact resistance.

- Aesthetic Value: Aluminum and copper claddings give modern architectural finishes.

- Thermal and Electrical Conductivity: Copper cladding ensures high conductivity for electronics and energy applications.

- Lightweight Solutions: Aluminum-based cladding reduces weight while maintaining durability.

Industry Applications of Metal Cladding Sheets

1. Construction and Architecture

Metal cladding sheets are widely used in building facades, roofing, wall systems, and decorative panels. They enhance weather resistance, fireproofing, and energy efficiency while offering attractive finishes.

Example: Copper cladding for luxury buildings, stainless steel panels for airports, aluminum cladding for high-rise towers.

2. Chemical and Petrochemical Industry

In chemical plants, metal cladding sheets such as titanium-clad steel resist strong acids and alkalis, making them suitable for reactors, pressure vessels, and heat exchangers.

Case: Titanium-clad steel plates used in desalination plants extend service life under seawater corrosion.

3. Power and Energy Industry

Power plants, nuclear facilities, and renewable energy systems adopt cladded plates for pipelines, condensers, and storage tanks.

Example: Nickel-clad steel ensures performance in high-temperature and high-pressure environments.

4.Transportation and Marine Engineering

Ships, offshore platforms, and automotive industries benefit from the lightweight yet strong properties of metal cladding sheets.

Case: Aluminum-clad steel sheets used in ship hulls reduce weight while preventing seawater corrosion.

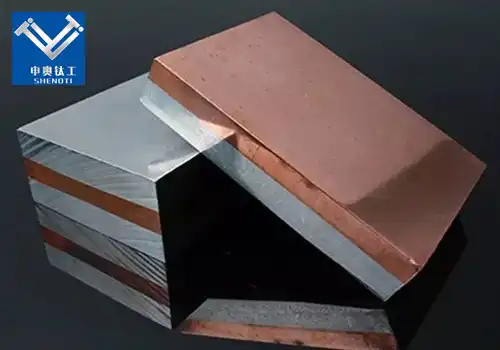

5. Electronics and New Energy

Copper-aluminum cladding sheets are increasingly applied in lithium batteries, EV connectors, and PCB boards due to their conductivity and lightweight nature.

Example: Copper-aluminum transition plates in electric vehicle batteries improve performance and cost efficiency.

|

|

|

|

|

|

|

Product production process

Metal Cladding Panel Case

1: Titanium-Clad Steel for Desalination

A Middle Eastern desalination project required corrosion resistance against seawater. Titanium-clad steel sheets were selected, extending service life by 25 years and reducing replacement costs.

2: Copper-Aluminum Cladding in EV Batteries

An electric vehicle manufacturer adopted copper-aluminum clad sheets for battery connectors. The result was lower weight, reduced material cost, and higher conductivity efficiency.

3: Stainless Steel Cladding in Architecture

A commercial skyscraper used stainless steel cladding sheets for exterior facades. The sheets provided a modern appearance, resistance to acid rain, and low maintenance requirements.

Why Choose Us?

At Baoji City ShenAo Metal Materials Co., Ltd., we stand out as a leader in metal cladding solutions. Here's why:

-

Research and Innovation

Our experienced R&D team continuously explores new processes and applications to enhance product performance. We stay ahead of the curve by incorporating cutting-edge technology to meet customer needs. -

Excellent Reputation

With over 17 years of experience in the industry, we have earned the trust and praise of customers worldwide. Our dedication to quality and reliable customer service is why many choose us as their preferred supplier. -

Striving for Excellence

Our commitment to excellence ensures that every product meets rigorous quality standards. We maintain strict production processes and a comprehensive quality management system, ensuring stability and reliability for our clients. -

Customized Product Services

We offer custom solutions for non-ferrous metal composites and multi-purpose titanium anodes to meet diverse client needs, ensuring each product is suited to its specific application. -

Timely Delivery and After-Sales Support

We prioritize customer satisfaction with timely delivery and comprehensive after-sales support, ensuring that all your needs are met promptly. -

OEM Services

We also offer OEM services, providing customized products to suit the specific requirements of your business.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

-

What industries can use cheap metal cladding sheets?

Our cladding sheets are widely used in chemical, marine, electrical, environmental protection, and medical industries, offering versatile solutions for various applications. -

Can I get custom sizes for my project?

Yes, we offer customized sizes and specifications to ensure that the metal cladding sheets meet the exact requirements of your project. -

What is the delivery time for orders?

We pride ourselves on timely delivery. Depending on the size of your order, we aim to ship products within 7-15 days after confirmation. -

Are the materials corrosion-resistant?

Yes, our cladding sheets are made from corrosion-resistant materials like copper, titanium, and nickel, making them ideal for applications in harsh environments.

Contact Us

For more information about our cheap metal cladding sheets or to place an order, feel free to contact us at:

Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

Contact Person: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

We look forward to providing you with the best products and service in the industry.

YOU MAY LIKE

_1752287642525.webp)