High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

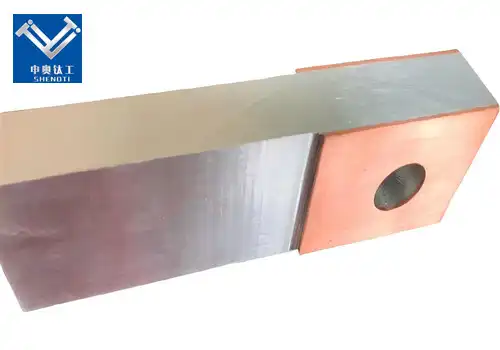

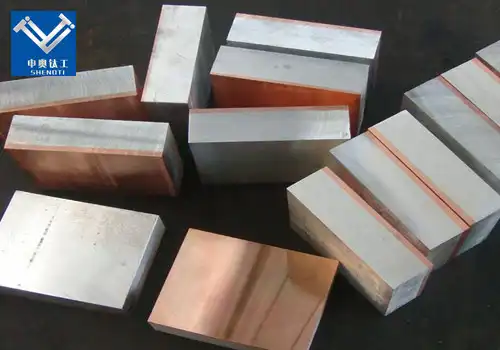

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

Copper Clad Aluminum Material: High-Performance Solution for a Variety of Industries

Introduction

Copper clad aluminum (CCA) is a specialized composite material that combines the superior conductivity of copper with the light weight and corrosion resistance of aluminum. This unique blend makes CCA a popular choice in industries requiring cost-effective, high-performance materials for electrical and mechanical applications. At Baoji City ShenAo Metal Materials Co., Ltd., we specialize in the manufacturing of high-quality copper-clad aluminum materials, offering a range of solutions for diverse sectors including electrical, chemical, and marine industries.

Whether you're looking for an efficient solution for power transmission or need corrosion-resistant materials for harsh environments, our copper-clad aluminum products deliver reliable performance. Explore the details below to learn more about our products and why Baoji City ShenAo Metal Materials Co., Ltd. is your go-to partner for copper-clad aluminum solutions.

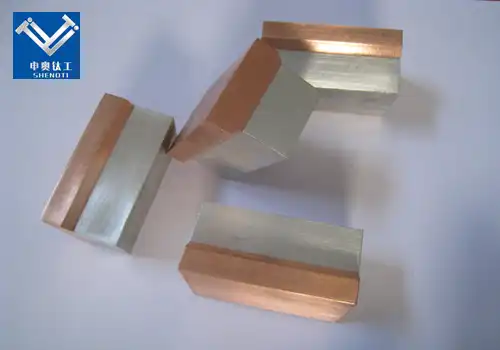

Classification of copper-aluminum composite materials

According to different uses and structural forms, copper-aluminum composite materials are mainly divided into the following types:

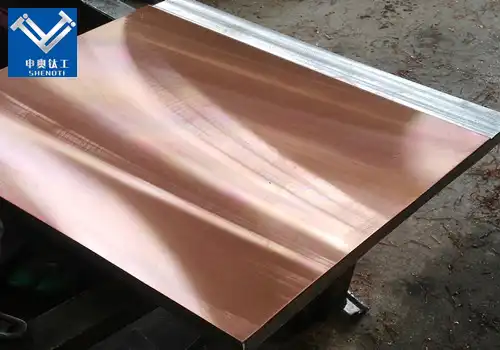

Double-layer structure: such as copper-aluminum composite plate (copper-coated aluminum), copper-aluminum composite strip.

Three-layer structure: such as copper-aluminum-copper (C-A-C) or aluminum-copper-aluminum (A-C-A) three-layer composite structure, used to improve double-sided electrical or thermal conductivity.

Special-shaped composite parts: such as copper-aluminum composite bars, copper-aluminum composite wires, etc., suitable for scenes requiring complex forming.

Technical Specifications

| Property | Value |

|---|---|

| Composition | Copper-clad on aluminum base material |

| Copper Clad Thickness | 0.5mm - 10mm (customizable) |

| Electrical Conductivity | > 55% IACS (International Annealed Copper Standard) |

| Density | 2.95 - 3.0 g/cm³ |

| Tensile Strength | 210 - 300 MPa |

| Yield Strength | 100 - 150 MPa |

| Elongation | 10 - 25% |

| Corrosion Resistance | Excellent in a wide range of environments |

| Operating Temperature | -40°C to 105°C |

| Surface Finish | Bright, smooth surface |

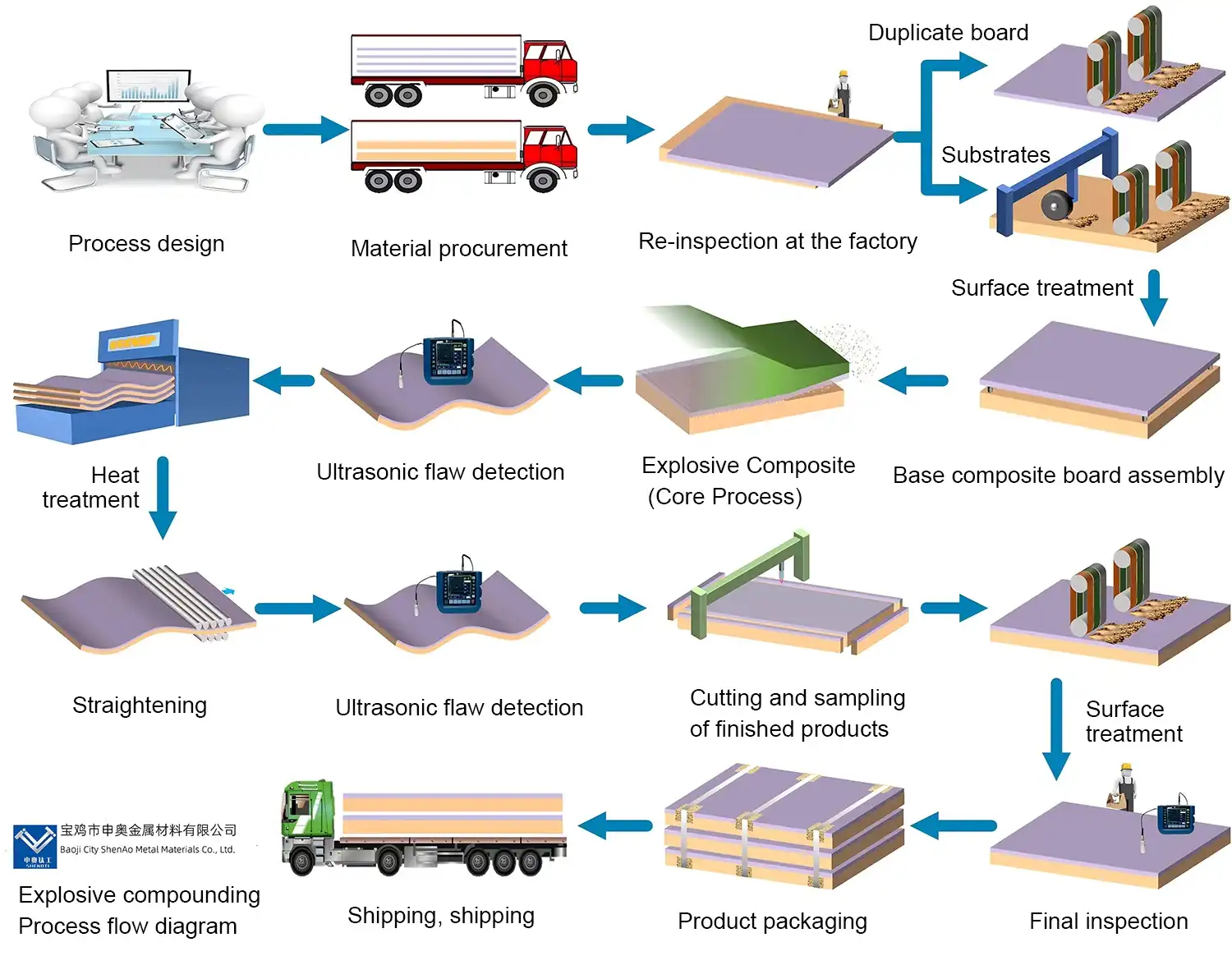

Preparation process of copper-aluminum composite materials

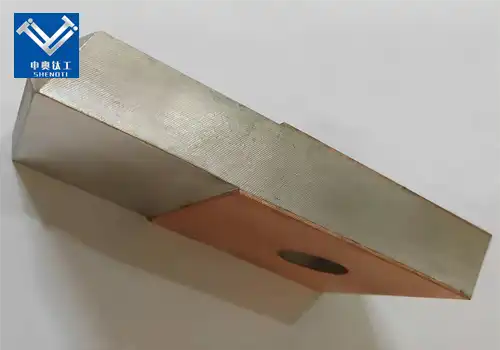

1. Explosive welding technology

Explosive welding is currently the most commonly used high-energy physical method for preparing copper-aluminum composite materials. Through explosives in a controlled environment, instantaneous high-voltage waves are triggered, so that copper and aluminum collide at high speed in a very short time and complete metallurgical bonding to form a bonding interface. This process can overcome the problem of brittle intermetallic compounds between copper and aluminum, and has a high-strength bonding effect.

2. Rolling composite process

Rolling composite is to press copper and aluminum into a whole at a certain temperature and pressure by hot rolling or cold rolling. This method is suitable for large-scale continuous production and is widely used in the preparation of copper-aluminum composite strips and plates.

|

|

|

|

|

|

Advantages of copper-clad aluminum materials

1. Excellent electrical and thermal conductivity

The copper layer gives the material excellent electrical conductivity (the electrical conductivity is close to that of pure copper), and the aluminum layer greatly reduces the overall density of the material, thereby achieving a lightweight and highly conductive performance combination, which is particularly suitable for the field of power electronics.

2. Excellent mechanical bonding strength

The metallurgical bonding interface formed by high-energy explosive welding or rolling composite has extremely high shear strength and anti-peeling properties, ensuring that no material delamination or breakage occurs during use.

3. Good processing and forming properties

Copper-clad aluminum materials can be sheared, bent, stamped, welded and other conventional metal processing operations according to specific needs. They are highly adaptable and suitable for the preparation of complex parts.

4. Significant cost advantage

The price of aluminum is much lower than that of copper. The use of copper can be greatly reduced through copper-clad aluminum materials, thereby significantly saving raw material costs and improving economic efficiency.

Application fields of copper-composite aluminum materials

1. Power and electronics industry

Copper-composite aluminum bars are widely used in low-voltage power distribution systems, bus ducts, switch cabinets and other equipment. They can effectively replace pure copper conductors to achieve lightweight and low cost. Copper-aluminum composite strips can also be used in cable connections, flexible connections and terminal blocks.

2. Automobiles and rail transit

In new energy vehicles, copper-composite aluminum materials are used for power battery connections, busbars and electronic control system wiring, taking into account both conductive performance and lightweight requirements to improve endurance efficiency.

3. Communication and heat dissipation systems

Copper-aluminum composite plates can be used in heat dissipation components such as 5G communication equipment and CPU radiators. The copper layer conducts heat quickly and the aluminum layer diffuses heat, effectively improving thermal management performance.

4. New energy and photovoltaic industry

Copper-composite aluminum bars are widely used in photovoltaic inverters, battery packs, and charging piles. They take into account current carrying capacity and weight control, and are important functional structural materials in photovoltaic systems.

|

|

|

|

|

|

|

Product production process

Why Choose Us

At Baoji City ShenAo Metal Materials Co., Ltd., we are committed to providing top-quality copper-clad aluminum materials. Here’s why you should choose us as your supplier:

-

Research and Innovation: We have a dedicated R&D team focused on creating innovative solutions tailored to your specific needs. Our products are constantly evolving to meet the demands of the latest technologies.

-

Excellent Reputation: With 17 years of industry experience, Baoji City ShenAo Metal Materials Co., Ltd. has earned a solid reputation for producing reliable, high-quality products. Our customers trust us for our consistency and performance.

-

Striving for Excellence: We adhere to strict production processes and quality management systems to ensure each product meets high industry standards. Whether you need small-scale or large-scale production, we guarantee timely delivery without compromising on quality.

-

Customized Product Services: We offer customized solutions to meet your unique requirements. Our team will work with you to deliver tailored copper-clad aluminum materials that suit your applications.

-

Timely Delivery and After-Sales Support: Our customer-centric approach ensures fast delivery times and exceptional after-sales support. We are always ready to assist you with any issues that may arise.

-

OEM Services: We also offer OEM services to meet specific branding or manufacturing requirements for your projects.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

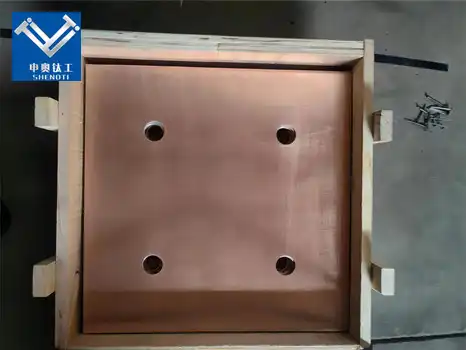

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

-

What is copper-clad aluminum? Copper-clad aluminum is a composite material where a thin layer of copper is bonded to an aluminum core. It combines the benefits of both metals: the conductivity of copper and the lightweight nature of aluminum.

-

What industries use copper-clad aluminum? CCA is used in industries like electrical and power, chemical, marine, automotive, aerospace, and environmental protection due to its excellent electrical conductivity and corrosion resistance.

-

How is copper-clad aluminum manufactured? The copper is bonded to the aluminum core using advanced processes such as explosive welding or cladding, ensuring strong adhesion and performance in various applications.

-

Can I customize the copper-clad aluminum material for my project? Yes, we offer customizable solutions in terms of size, thickness, and surface finish to meet your specific requirements.

Contact Us

We are ready to provide the best copper-clad aluminum solutions for your business. Get in touch with us today to discuss your needs!

Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

This page is designed with our customers' needs in mind, offering detailed information about copper-clad aluminum materials, their specifications, features, applications, and why Baoji City ShenAo Metal Materials Co., Ltd. is the right choice for your business. Through our commitment to innovation, quality, and customer satisfaction, we continue to lead the way in providing high-performance metal solutions.