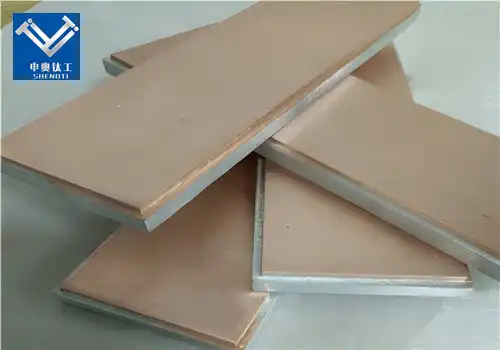

High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

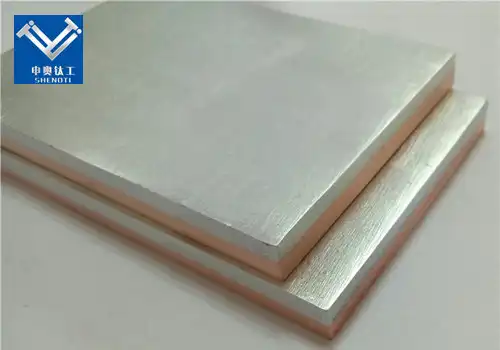

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

T2 copper is a high-purity oxygen-free copper (copper content ≥ 99.90%) in the national standard. It is characterized by high conductivity, good ductility, and strong corrosion resistance. It is an important raw material for manufacturing electrical and electrical components. Its material number is "TU1" or "T2", which corresponds to ASTM C11000 internationally.

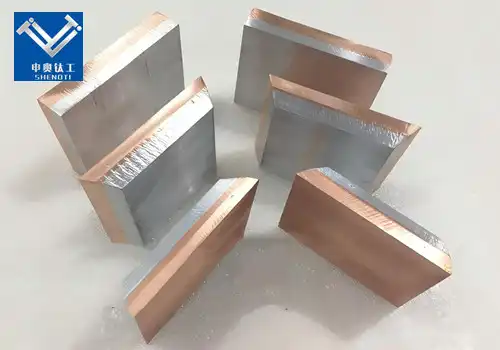

T2 copper composite plate refers to a composite metal plate formed by firmly combining T2 copper with other metals (such as stainless steel, aluminum, steel plate, etc.) by physical or chemical means. This material combines the high conductivity of T2 copper with the structural strength of the substrate and is widely used in electronics, chemical industry, electricity, new energy and other fields.

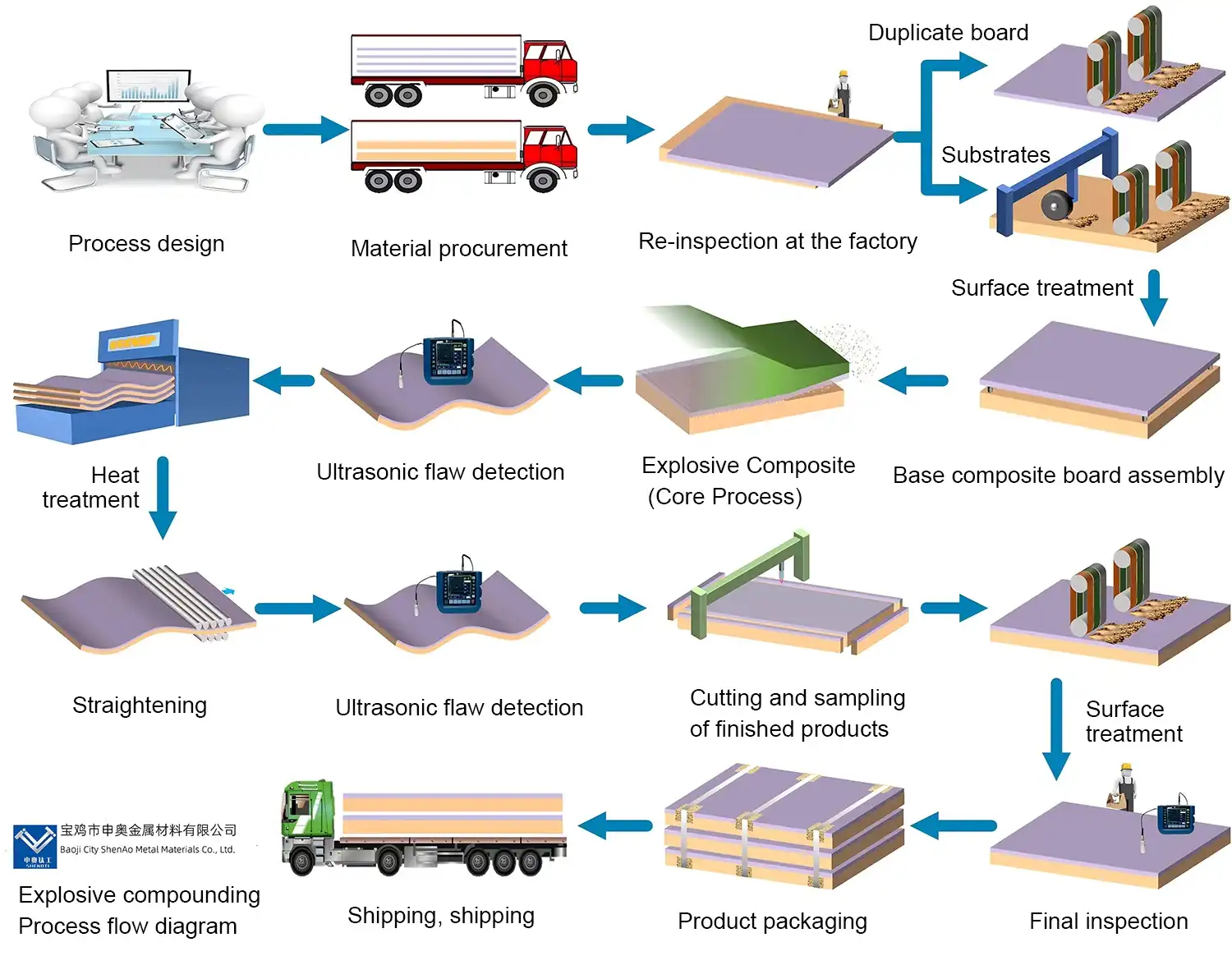

Main manufacturing process of T2 copper composite plate

1. Explosive welding process

Explosive welding is currently the most commonly used method for preparing T2 copper composite plates. It uses the high-speed impact force generated by the explosion wave to achieve metallurgical bonding between the copper plate and the substrate in an instant. This method not only has high bonding strength, but also can achieve large-area connection between different metals.

Process advantages:

Not limited by the difference in metal melting points;

The diffusion layer between the metals at the bonding interface is thin and the performance is stable;

The cost is controllable and suitable for mass production.

2. Hot rolling composite process

Hot rolling composite is to roll T2 copper and the substrate multiple times at high temperature so that the two materials can be metallurgically bonded through diffusion. This method is suitable for application scenarios with uniform structure and high interface requirements.

Process characteristics:

Uniform bonding and high interface bonding strength;

Multi-layer composite structure design can be carried out;

More conducive to subsequent mechanical processing and forming.

Technical Specifications

| Property | Specification |

|---|---|

| Material Composition | Bronze (CuZn) bonded to Steel/Aluminum |

| Thickness | 0.5mm to 5mm |

| Width | 1000mm, 1250mm, or customized |

| Length | 2000mm, 2500mm, or customized |

| Tensile Strength | 300 MPa |

| Elongation | ≥ 15% |

| Corrosion Resistance | High, suitable for marine and industrial environments |

| Surface Finish | Smooth, Polished, Brushed, or Customized |

| Applications | Construction, Marine, Electronics, HVAC |

| Thermal Conductivity | 125 W/m·K |

| Density | 8.9 g/cm³ |

|

|

|

|

|

|

Performance advantages of T2 copper composite plate

1. Excellent electrical conductivity

The conductivity of T2 copper itself can reach more than 97%, which is one of the best performing common conductive materials. Compared with ordinary copper, it has higher purity and can effectively reduce resistance loss.

2. Excellent corrosion resistance

T2 copper has good corrosion resistance in most industrial media, especially suitable for chemicals, salt spray environment and acid-base medium, extending the service life of equipment.

3. Good machinability and weldability

Whether it is cutting, stamping, bending or welding, T2 copper composite plate shows excellent processing performance and can meet the manufacturing requirements of a variety of complex structural parts.

4. Comprehensive cost advantage of materials

By combining T2 copper with low-cost steel plates or aluminum materials, it can not only maintain excellent performance, but also significantly reduce material costs. It is an ideal alternative to traditional pure copper plates.

1. Electronic and electrical industry

Due to its high conductivity and processing convenience, T2 copper composite board is widely used in the manufacture of high-demand conductive structural parts such as bus ducts, transformer conductors, cable connectors, and electromagnetic shielding shells.

2. Chemical equipment manufacturing

In chemical reaction vessels, heat exchangers, and pipeline linings that require corrosion resistance and fast thermal conductivity, T2 copper composite boards can replace expensive pure copper structures and improve equipment stability and economy.

3. New energy and rail transportation

In new energy battery connection systems, high-speed rail and subway electric control systems, T2 copper composite boards are used as conductive bridges to significantly improve system transmission efficiency and reduce energy loss.

4. Construction and decoration fields

T2 copper composite boards are also commonly used in high-end building curtain walls, elevator decorative panels, metal furniture and handicraft designs due to their unique metallic luster and elegant texture.

Quality inspection and standards of T2 copper composite plate

In order to ensure the stable performance of T2 copper composite plate, it is necessary to conduct inspections according to the following standards:

Metallurgical bonding inspection: Microstructure inspection to check whether there are cracks or unbonded areas at the bonding interface;

Shear strength test: Comply with national standards such as GB/T 26492 to ensure the overall shear resistance of the plate;

Conductivity test: Use eddy current or resistivity instruments for comparison to ensure that the conductivity of the T2 copper layer reaches the designed value;

Thickness consistency inspection: Use ultrasonic or laser thickness gauge to ensure the uniformity of the composite layer.

|

|

|

|

|

|

|

Product production process

Why Choose Us?

Our Advantages

-

Research and Innovation

Baoji City ShenAo Metal Materials Co., Ltd. is committed to research and development, ensuring we stay ahead of industry trends. Our technical team constantly explores new materials, processes, and applications, delivering innovative solutions to our clients. -

Excellent Reputation

With 17 years of experience, our brand has earned the trust of customers worldwide. We take pride in our reputation for providing high-quality products and exceptional customer service. -

Striving for Excellence

We adhere to stringent production processes and a comprehensive quality management system, ensuring that every product meets industry standards. Whether small-batch or large-scale production, we guarantee timely delivery and product reliability. -

Customized Product Services

We offer tailored solutions for various non-ferrous metal composite materials and titanium anodes. Our customized services ensure we meet the specific technical and usage requirements of each customer. -

Timely Delivery and Worry-Free After-Sales Service

Our customer-centric approach ensures timely delivery and reliable after-sales support, helping you solve any issues swiftly and efficiently. -

OEM Services

We provide OEM services to meet the unique needs of customers across different sectors, ensuring flexibility in design and production.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

-

What industries use bronze sheet metal cladding?

Bronze sheet metal cladding is commonly used in the construction, marine, electronics, and chemical industries, among others. Its corrosion resistance and aesthetic appeal make it suitable for a wide range of applications. -

Can I customize the size and thickness of the bronze sheet metal cladding?

Yes, we offer customization options for both size and thickness to meet your specific needs. Whether you require a thinner sheet for architectural applications or a thicker sheet for industrial use, we can accommodate your requests. -

Is bronze sheet metal cladding resistant to seawater?

Yes, bronze is highly resistant to seawater corrosion, making it an excellent material choice for marine environments such as shipbuilding, offshore platforms, and seawater desalination projects. -

What is the typical lead time for bronze sheet metal cladding orders?

Lead times vary depending on the size and complexity of the order. However, we prioritize timely delivery and work closely with our clients to ensure efficient order fulfillment. -

How do I maintain bronze sheet metal cladding?

Bronze cladding requires minimal maintenance. Regular cleaning and occasional polishing will help maintain its aesthetic appearance and prevent corrosion buildup.

Contact Details

For more information or to place an order, feel free to reach out to us:

Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

We look forward to providing you with the most professional service and high-quality bronze sheet metal cladding solutions!

This content is structured to be SEO-optimized for the keyword "bronze sheet metal cladding," naturally incorporating related terms to enhance readability while maintaining keyword relevance. The tone is conversational and engaging, ensuring it appeals to both technical and non-technical readers.