Sheet Metal Cladding Process: A Comprehensive Overview

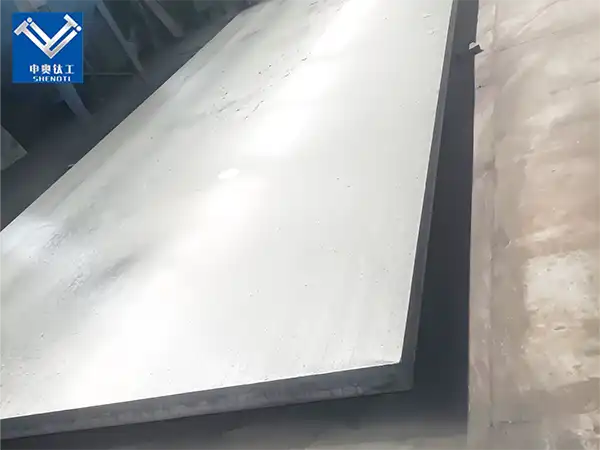

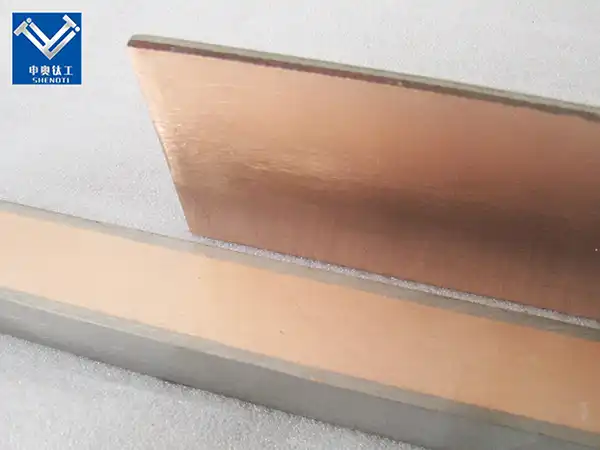

Carbon steel composite plate is composed of two or more layers of metal materials with different properties. The base material is carbon steel, and the covering material may be corrosion-resistant metals such as 304/316 stainless steel, titanium, copper or nickel depending on the purpose.

Common composite forms include:

Bimetallic Plate: such as stainless steel + carbon steel composite plate.

Multilayer Plate: three or more layers of composite metal structure, such as stainless steel + carbon steel + aluminum composite plate.

These composite plates have both structural bearing and surface performance functions, which are difficult to match with traditional single materials.

Technical standards for carbon steel composite plates

The technical requirements for carbon steel composite plates at home and abroad mainly refer to the following standards:

GB/T 8165 "Composite steel plates for pressure vessels"

American standards such as ASTM A264 / A265 / A263

ASME Boiler and Pressure Vessel Code (ASME Code)

These standards put forward strict control indicators for carbon steel composite plates in terms of composite quality, bonding strength, thickness deviation, etc.

Main production processes of carbon steel composite plates

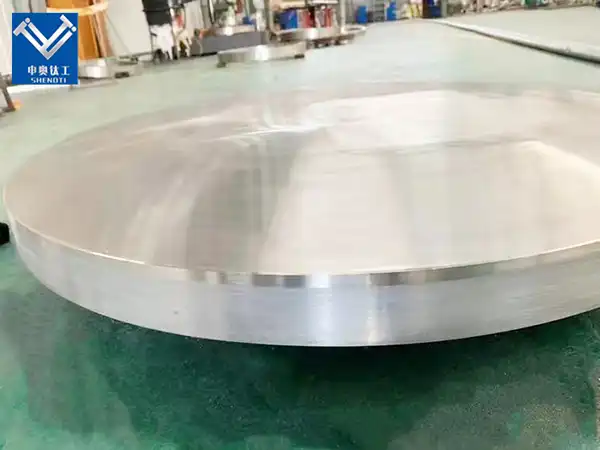

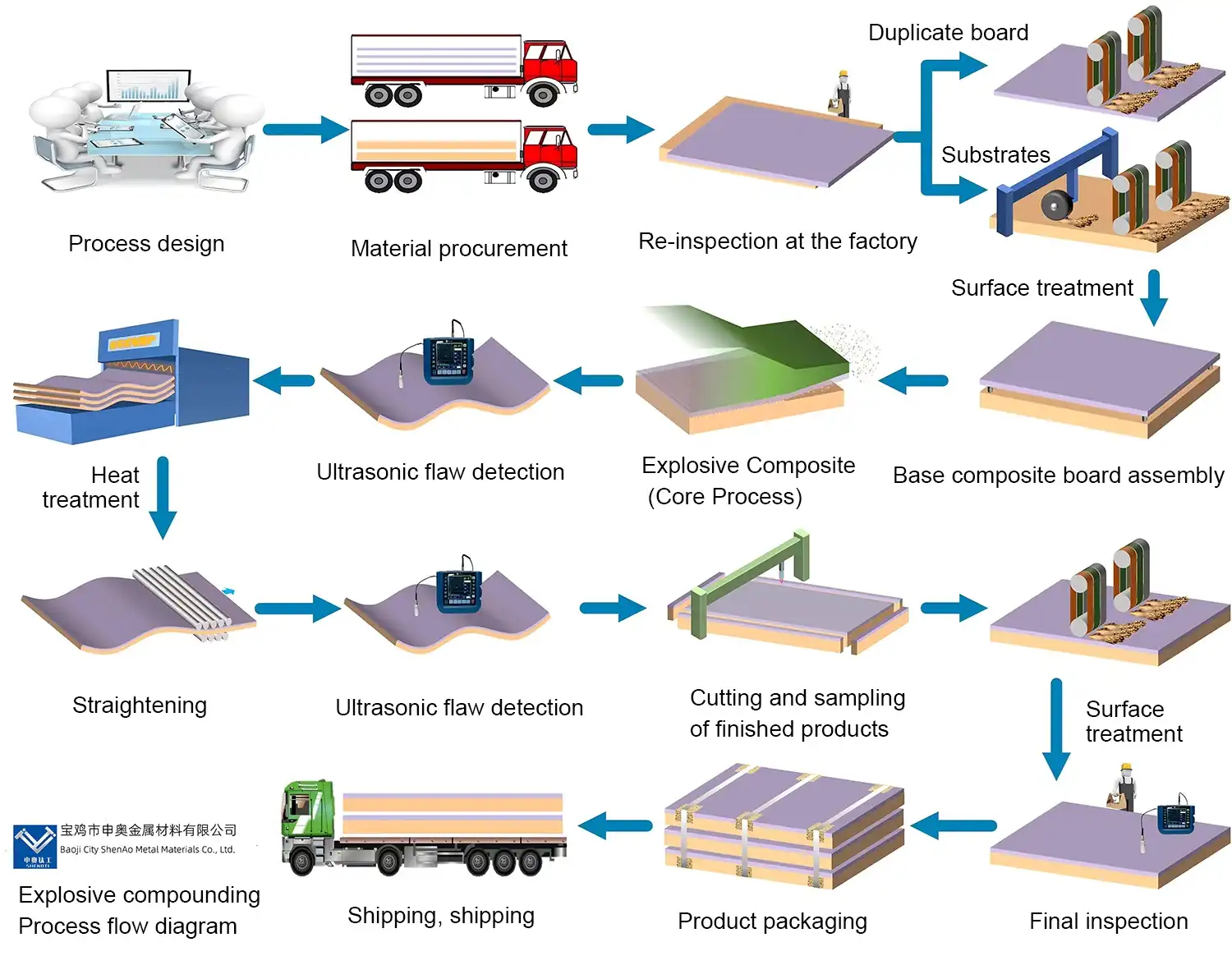

1. Explosive composite method

Explosive composite is a technology that uses the shock wave released instantly by high-energy explosives to press carbon steel and composite metal at a very high speed. Its advantages include:

Can composite large areas and multiple metal combinations

High bonding strength, metallurgical bonding rate can reach more than 98%

Suitable for the combination of dissimilar metals, such as carbon steel + titanium, stainless steel + carbon steel, etc.

2. Hot rolling composite method

The hot rolling composite method is to heat the two metals to a plastic state and then combine them through multiple rolling. It is widely used in continuous mass production and is suitable for the combination of carbon steel with stainless steel, copper and other metals.

3. Explosive + rolling composite

In order to make up for the defects of a single method, some high-end applications use a composite process of first explosive composite and then hot rolling finishing, which has both bonding strength and surface flatness. It is one of the mainstream high-end preparation processes for carbon steel composite plates.

In actual projects, choose the appropriate type of carbon steel composite plate:

|

Use environment |

Recommended composite metals |

Recommended combination |

|

Strong acid and alkali |

Titanium, Hastelloy |

Ti+Q235 |

|

Neutral corrosion |

Stainless steel 304/316 |

SUS304+Q345R |

|

High temperature environment |

Nickel, molybdenum alloy |

Ni+Q235B |

|

Food grade hygiene |

316L stainless steel |

SUS316L+Q345R |

These products are designed to withstand harsh environments, ensuring reliability and performance over long periods.

|

|

|

|

|

|

|

|

Technical advantages of carbon steel composite plates

1. Reduce costs

By using cheap carbon steel as the main material and only using precious metal composite layers on the surface, the overall material cost is greatly reduced, which is particularly suitable for the manufacture of large-area corrosion-resistant equipment.

2. Improve performance

The composite metal has good corrosion resistance, oxidation resistance, and high temperature resistance, which significantly extends the life of the equipment while maintaining high-strength structural performance.

3. Green and environmentally friendly

The use of carbon steel composite plates can reduce unnecessary metal waste, which is in line with the trend of energy conservation and carbon reduction; its recyclability is also conducive to the realization of circular manufacturing.

4. Strong process adaptability

Carbon steel composite plates can be processed by conventional cutting, welding, rolling and other processes, without the need for special equipment, which is conducive to rapid docking in downstream manufacturing links.

Main application areas of carbon steel composite plates

1. Petrochemical equipment

The petrochemical industry widely uses carbon steel composite plates to manufacture pressure vessels, heat exchangers, storage tanks and other equipment. Carbon steel provides structural support for the main body, and stainless steel or titanium composite layers resist erosion by corrosive media.

Application scenarios:

High-pressure heat exchangers in oil refining

Inner walls of towers in fertilizer plants

Inner linings of acid and alkali storage tanks

2. Power and energy industry

Thermal power plants and nuclear power plants involve a large number of high-temperature and high-pressure devices, which have extremely high requirements for the pressure resistance and corrosion resistance of materials. Carbon steel composite plates can be used as an ideal choice for boiler tube plates, superheater components, etc.

3. Marine engineering

In seawater environment, single carbon steel is easily corroded, while pure titanium or stainless steel is expensive. Carbon steel composite plates achieve a balance between economy and corrosion resistance through titanium/stainless steel composite layers and are widely used in:

Seawater desalination equipment

Offshore platform pipelines

Hull corrosion-resistant coating materials

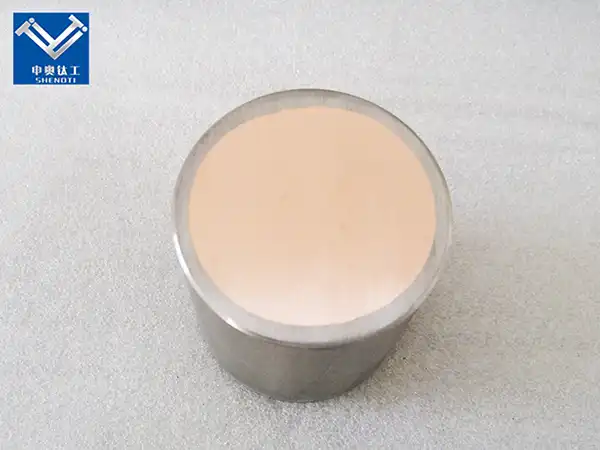

4. Food and medical equipment

In the process of food processing or pharmaceutical manufacturing, it is necessary to avoid pollution caused by metal ion precipitation. Stainless steel + carbon steel composite plates are often used to manufacture equipment such as reactors and mixing tanks.

|

|

|

|

|

|

|

Product production process

Why Choose Us: Our Advantages

At Baoji ShenAo Metal Materials Co., Ltd., we pride ourselves on our technical expertise, innovative approach, and dedication to customer satisfaction. Here are a few reasons why you should choose us:

- Research and Innovation: Our professional R&D team is constantly working to improve and innovate, ensuring our products stay at the cutting edge of technology.

- Excellent Reputation: With 17 years of experience, we have earned the trust of numerous clients by providing reliable, high-quality products and services.

- Striving for Excellence: We adhere to strict quality control processes and a comprehensive management system to ensure all products meet the highest standards.

- Customized Product Services: We offer tailored solutions to meet the unique needs of different industries, ensuring our products meet specific technical requirements.

- Timely Delivery and After-Sales Service: We are committed to providing timely deliveries and offering comprehensive after-sales support to ensure customer satisfaction.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

OEM Services

We also offer OEM services, allowing you to get custom-made products according to your specific requirements. Whether you need unique metal cladding combinations, specialized coatings, or specific material sizes, we can meet your needs with precision.

Frequently Asked Questions (FAQs)

-

What is the sheet metal cladding process? The sheet metal cladding process involves bonding two or more metals to combine their best properties, such as corrosion resistance, strength, and conductivity.

-

What metals can be used in cladding? Common cladding combinations include copper with aluminum, steel, or titanium, depending on the required application.

-

How long does the cladding process take? The timeline depends on the complexity and size of the order. Typically, the process is completed within a few weeks, with custom orders taking slightly longer.

-

Are these cladded materials customizable? Yes, we offer customized cladding solutions based on your specific material needs and application requirements.

Contact Us

For more information or to request a quote, feel free to contact us. We provide professional and prompt customer service to ensure your needs are met.

- Company: Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Conclusion

At Baoji ShenAo, we are committed to providing high-quality sheet metal cladding process solutions that meet the needs of industries requiring durable, reliable, and cost-effective materials. Our advanced manufacturing techniques and commitment to innovation ensure that our products deliver the performance and reliability you need. Contact us today to discuss how our products can support your next project.