High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

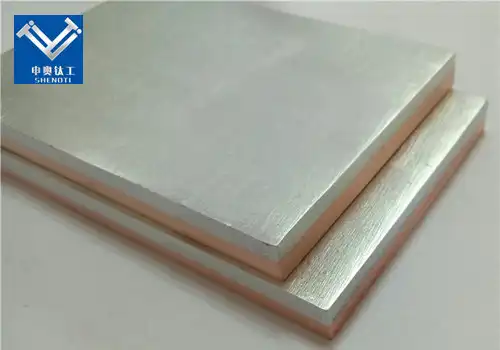

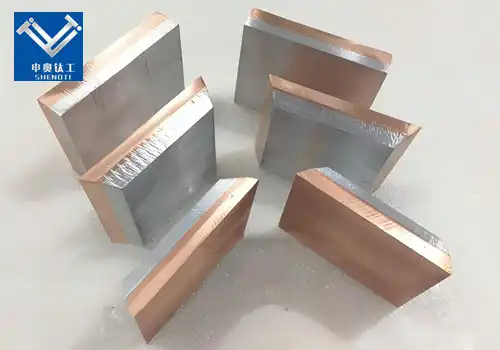

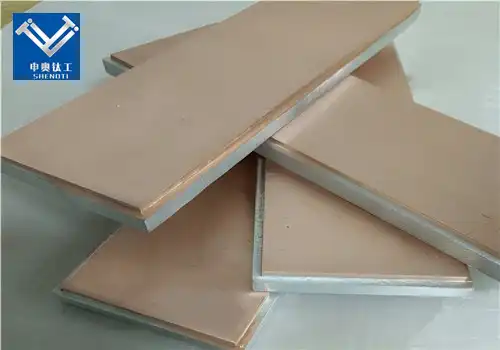

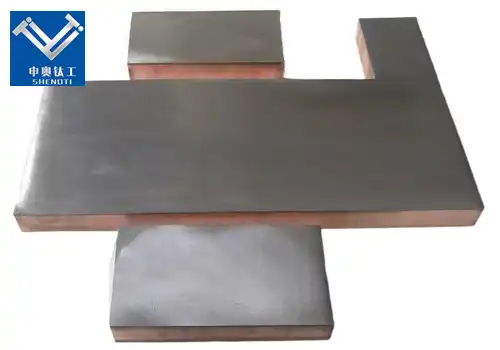

Clad Metal Sheet

Composite metal plates are made of two or more metal materials with different physical and chemical properties, which are firmly bonded at the interface through certain process methods. Through the "complementary advantages" approach, a combination of properties that are difficult to be achieved with a single metal material, such as corrosion resistance, strength, thermal conductivity, and machinability, is obtained.

Composite structure type

Double-layer composite metal plate: such as stainless steel + carbon steel, copper + aluminum, titanium + steel, etc.;

Three-layer composite metal plate: such as copper + aluminum + copper, stainless steel + aluminum + stainless steel, etc.;

Multi-layer composite metal plate: used in more complex structural requirements, such as high-voltage equipment or aerospace components.

Comparison between composite metal panels and traditional materials

|

Performance Dimensions |

Single Metal Plate |

Clad Metal Plate |

|

Cost control |

High |

Significantly reduced |

|

Corrosion resistance |

Metal dependent |

Customizable |

|

Strength |

Dependent on substrate |

High-strength bond |

|

Processability |

Low-consumption tooling |

Flexible design |

Manufacturing process of composite metal plates

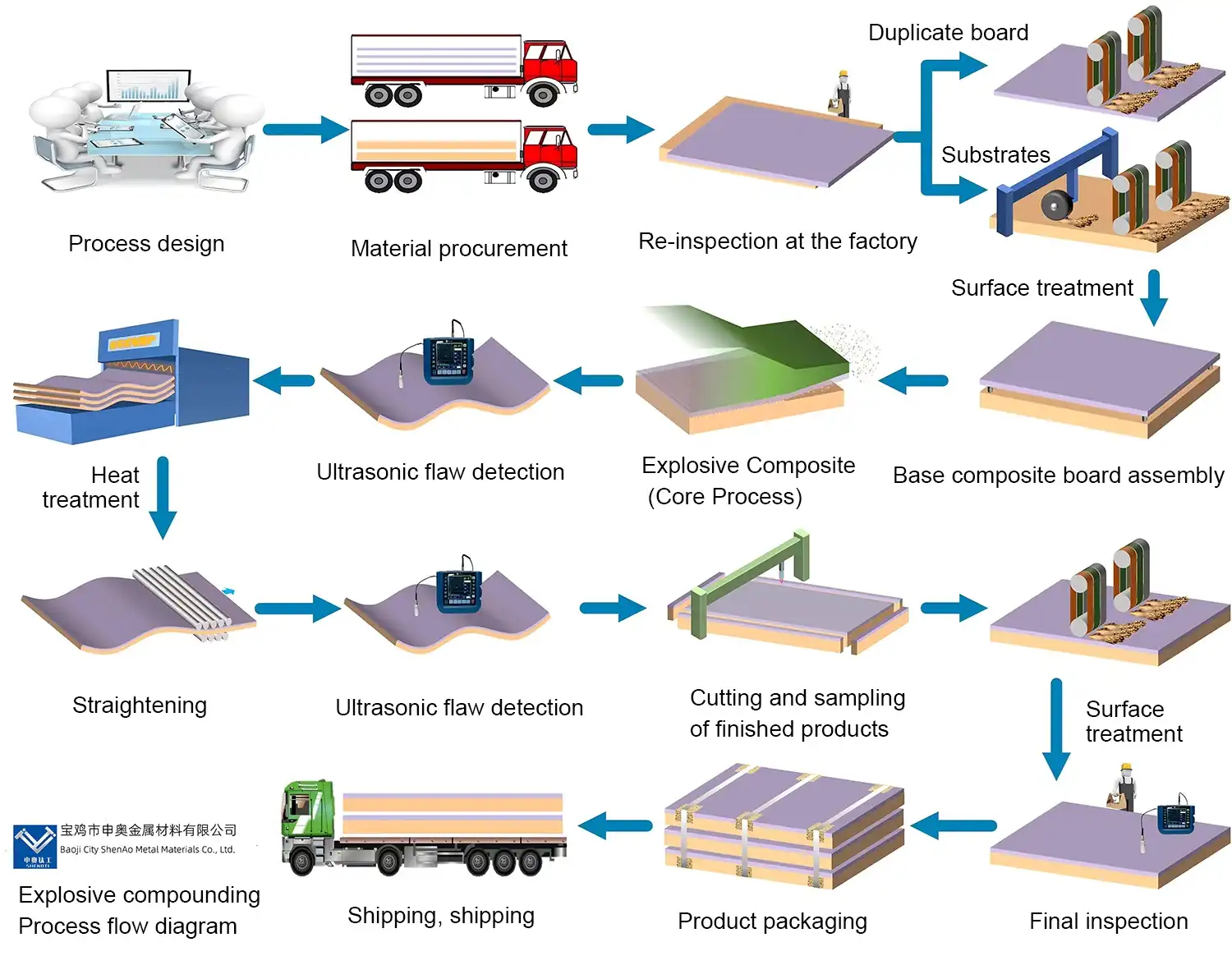

1. Explosive welding

Explosive welding is a solid-state welding process that uses high-energy shock waves generated by explosives to connect two metal materials together at ultra-high pressure in a very short time.

Advantages:

Almost all metal combinations can be connected;

High bonding strength;

Small thermal impact, and the metal structure remains basically unchanged.

2. Hot rolling composite

By stacking two or more metal plates under high temperature conditions and rolling them simultaneously, they are metallurgically bonded under the action of heat.

Applicable scenarios:

Massive industrial production;

Occasions with high requirements for surface bonding.

3. Explosive + rolling composite

Pre-bonding by explosive welding first, and then using hot rolling to enhance the bonding interface and material properties, is a combined manufacturing method with better performance.

|

|

|

|

|

|

Performance advantages of composite metal plates

1. Performance integrationThe biggest technical advantage of composite metal plates is that they can integrate the advantages of two or more metal materials. For example, the outer layer uses corrosion-resistant stainless steel or titanium, and the inner layer uses high-strength, low-priced carbon steel or aluminum, which greatly reduces costs while ensuring durability.

2. Cost optimization

On the premise of meeting engineering performance, by reducing the amount of expensive alloy materials, the cost of raw materials can be significantly saved. This is especially important for the manufacture of bulk equipment such as petrochemical containers and power heat exchangers.

3. Customizable design

Different application scenarios have significantly different requirements for metal performance. Through composite technology, companies can customize composite metal plates of different thicknesses, material combinations, and sizes according to needs, which is more flexible.

4. Strong process adaptability

Composite metal plates are suitable for conventional processing processes such as welding, stamping, deep drawing, bending, etc., which facilitates efficient connection of downstream manufacturing links.

Application fields of composite metal plates

1. Petrochemicals

Petrochemical equipment such as storage tanks, heat exchangers, reactors, etc. often work in high temperature, high pressure, and highly corrosive environments, requiring materials that are both corrosion-resistant and strong. Composite metal plates such as titanium-steel and stainless steel-carbon steel have become the preferred materials.

2. Electric power

Power station condenser tube sheets, flue gas desulfurization devices, nuclear power equipment, etc. have extremely high requirements for material performance. The use of composite metal plates can significantly improve corrosion resistance and service life and reduce maintenance frequency.

3. Aerospace

Aerospace structural parts often require lightweight and high-strength materials. High-performance composite metal plates such as aluminum-titanium composite plates and magnesium-aluminum composite plates are widely used in aircraft skins, structural frames, etc.

4. Building decoration

Stainless steel-aluminum composite plates and stainless steel-copper composite plates are widely used in high-end building curtain walls, elevator interiors, decorative panels, etc. due to their excellent decorativeness, weather resistance and processability.

5. Electronic communications

Electronic equipment housings and internal structural parts have requirements for electromagnetic shielding, heat dissipation and lightweight. Composite metal plates provide a variety of functional solutions for them.

|

|

|

|

|

|

|

Product production process

Why Choose Us

1. Research and Innovation

Baoji City ShenAo Metal Materials Co., Ltd. boasts a dedicated R&D team focused on developing new processes and products. Our team is committed to staying ahead of the curve, continuously enhancing our offerings to meet the evolving needs of our clients.

2. Excellent Reputation

With over 17 years of experience in the industry, our company has built a solid reputation for quality and reliability. The Baoji ShenAo Metal brand is trusted and praised by customers worldwide for its consistent performance and outstanding service.

3. Striving for Excellence

Our long-standing history of stable production and rigorous quality control ensures that every product meets the highest standards. We deliver products that exceed expectations, with quick turnaround times and impeccable quality.

4. Customized Product Services

We provide tailored solutions to meet the specific needs of our clients, whether it's for unique metal combinations, custom sizes, or specialized applications. Our flexible approach ensures the right product for every customer.

5. Timely Delivery, Worry-Free After-Sales Service

We prioritize customer satisfaction by offering timely delivery and reliable after-sales support. Our team is always ready to assist with any issues or queries, ensuring a smooth and hassle-free experience.

6. OEM Services

As a customer-centric company, we offer OEM services to meet the diverse requirements of our clients, providing personalized products and solutions.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q: What is a clad metal sheet? A: A clad metal sheet is a composite material made by bonding two or more metals together, providing the benefits of both materials. This combination enhances properties like corrosion resistance, conductivity, and mechanical strength.

Q: What are the main applications of clad metal sheets? A: Clad metal sheets are used in a variety of industries, including chemical processing, wastewater treatment, power generation, marine applications, and medical devices.

Q: How can I customize a clad metal sheet? A: We offer customization options for thickness, material combinations, surface finishes, and sizes to meet your specific needs.

Q: What is the lead time for an order? A: Lead times vary depending on the complexity of the order. We strive for timely delivery and will provide you with an estimated timeline when you place an order.

Contact Details

We are committed to providing you with the most professional service. Feel free to contact us for inquiries or to place an order:

- Company Name: Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- E-mail: zh@baojiti.com.cn

This page is designed to provide valuable information about our high-quality clad metal sheets, offering a clear understanding of their benefits, specifications, and applications. Whether you're in the chemical, energy, environmental protection, or marine industries, Baoji City ShenAo Metal Materials Co., Ltd. is your trusted partner for superior metal materials.