In today’s evolving industrial landscape, titanium electrodes have become one of the most critical components across electrochemical, environmental, and energy-related industries. With exceptional corrosion resistance, electrical conductivity, and mechanical stability, titanium electrodes enable efficient and sustainable production processes in electroplating, water treatment, electrolysis, and other specialized fields.

What Are Titanium Electrodes?

Titanium electrodes are electrochemical components made from high-purity titanium metal, often coated with noble metal oxides such as ruthenium (Ru), iridium (Ir), platinum (Pt), or mixed metal oxides (MMO). These coatings enhance the electrode’s catalytic activity and extend its operational life under high-current, corrosive, or high-temperature conditions.

Technical Parameters of Titanium Electrodes

|

Parameter |

Specification |

|

Base Material |

Gr1 / Gr2 Titanium |

|

Coating Type |

Ru-Ir, Pt, MMO, Ir-Ta |

|

Coating Thickness |

5–10 μm |

|

Operating Current Density |

1000–15000 A/m² |

|

Working Temperature |

≤ 80°C (customizable) |

|

Service Life |

5–10 years depending on environment |

|

Application Areas |

Electrolysis, wastewater treatment, chlor-alkali, hydrogen generation |

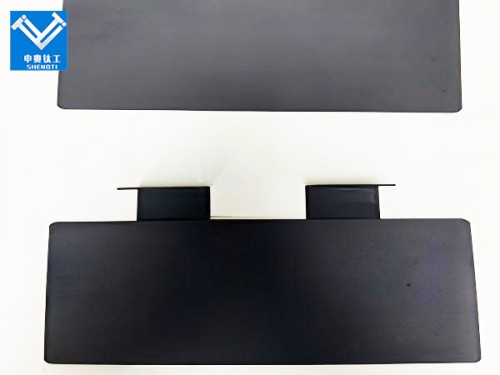

Types of Titanium Electrodes

Different industries demand customized electrode types to meet specific electrochemical reactions. Common varieties include:

1. MMO Titanium Electrodes (Mixed Metal Oxide)

These are the most widely used titanium electrodes, featuring coatings of ruthenium–iridium or iridium–tantalum oxides. They are ideal for electrolytic chlorine generation, wastewater treatment, and cathodic protection systems.

2. Platinum-Coated Titanium Electrodes

Platinum-coated electrodes offer exceptional conductivity and are widely used in laboratory electrolysis, electroplating, and hydrogen generation. Their high cost is offset by unmatched performance and stability.

3. Ruthenium-Iridium Coated Titanium Electrodes

With balanced oxidation resistance and catalytic activity, Ru–Ir titanium electrodes are commonly applied in seawater electrolysis, oxidation of organic pollutants, and electrochemical synthesis.

4. Dimensionally Stable Anodes (DSA)

DSA titanium electrodes maintain constant geometry during operation, ensuring consistent current distribution. They are extensively used in chlor-alkali industries, metal recovery, and electro-deposition.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Functional Advantages of Titanium Electrodes

Excellent corrosion resistance in acidic, alkaline, and chloride environments.

High current efficiency and low energy consumption.

Long service life with minimal maintenance requirements.

Environmentally friendly—no toxic metal leaching.

Customizable geometry for diverse electrochemical applications.

Applications of Titanium Electrodes Across Industries

The versatility of titanium electrodes allows them to be deployed in numerous industrial sectors.

1. Water Treatment Industry

Titanium electrodes are vital in electrochemical oxidation, disinfection, and electroflocculation systems. They help remove pollutants, heavy metals, and organic matter efficiently without adding secondary chemicals.

Typical use cases include:

Industrial wastewater treatment

Seawater desalination pre-treatment

Swimming pool and drinking water disinfection

2. Electroplating and Metal Finishing

In electroplating, titanium electrodes provide a stable, inert anode material that resists corrosion and prevents contamination of plating baths. They are used in:

Chrome plating

Copper and nickel electroplating

Precious metal recovery

3. Chlor-Alkali and Chemical Processing

Titanium electrodes are the backbone of chlorine and caustic soda production. Their durability under high chloride concentrations ensures long-term efficiency in:

Brine electrolysis

Hypochlorite generation

Sodium chlorate synthesis

4. Hydrogen and Energy Production

In hydrogen generation via water electrolysis, titanium electrodes with platinum or MMO coatings act as efficient catalysts. They offer low overpotential and high current density—crucial for green hydrogen projects and renewable energy systems.

5. Cathodic Protection Systems

Titanium anodes play a key role in protecting pipelines, offshore platforms, and storage tanks from corrosion. Their long service life and stable output make them preferred for marine engineering and oil & gas applications.

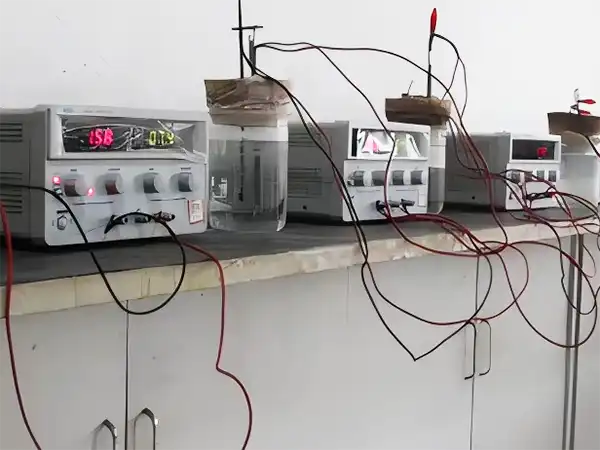

Case Studies: Titanium Electrodes in Action

1. Electrochemical Wastewater Treatment in Electronics Manufacturing

A major electronics manufacturer in Southeast Asia adopted ShenAo’s MMO titanium electrodes for treating copper- and ammonia-containing wastewater. The electrodes achieved 95% COD removal efficiency while maintaining stable operation for over three years.

2. Chlorine Generation System for Seawater Pools

In Europe, ShenAo’s Ru–Ir titanium electrodes are installed in seawater chlorination systems. The design ensures long service life and consistent chlorine output, reducing maintenance frequency and operational costs.

3. Hydrogen Production Pilot Project

A renewable energy company integrated platinum-coated titanium electrodes into a 500 kW hydrogen production unit. The electrodes delivered excellent gas purity and maintained performance across thousands of cycles.

|

|

|

|

|

|

|

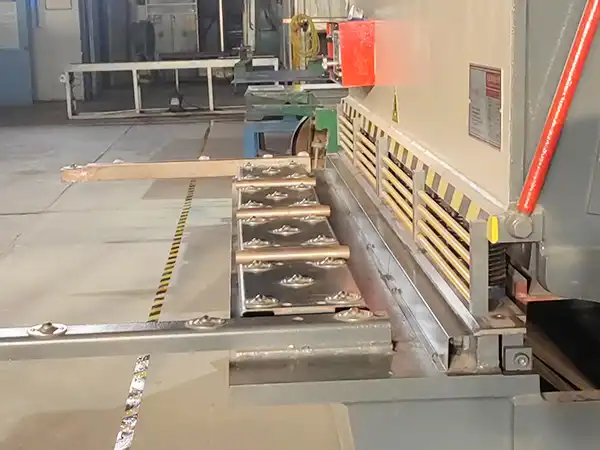

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Research and Innovation

With a dedicated R&D team, Baoji City ShenAo Metal Materials Co., Ltd. continuously explores advanced processes, ensuring cutting-edge product development and application.

Excellent Reputation

For over 17 years, we’ve delivered high-quality electrodes trusted by customers worldwide.

Striving for Excellence

Our rigorous production standards and quality management systems guarantee product reliability and customer satisfaction.

Customized Services

We provide tailored solutions for diverse industrial needs, ensuring every product meets exact specifications.

Timely Delivery and After-Sales Support

Our customer-focused approach ensures on-time delivery and responsive support for all orders.

OEM Services

We offer unique hardware fabricating (OEM) administrations to offer assistance clients extend their showcase nearness with personalized arrangements. Our group works closely with you to make customized items that adjust with your brand personality and particular execution prerequisites. By leveraging our skill in titanium materials and cutting-edge fabricating forms, we give high-quality, custom fitted arrangements that meet the special requests of your commerce. Whether you're looking to upgrade existing items or create modern advancements, we are committed to conveying extraordinary comes about that drive development and guarantee long-term victory in your showcase.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What makes our electrodes different from other types of electrodes?

Our electrodes combine excellent corrosion resistance with superior conductivity, making them ideal for harsh industrial environments.

Q2: Can our electrodes be customized for specific applications?

Yes, we offer fully customizable solutions, including dimensions, coatings, and designs, to suit unique industrial requirements.

Q3: What is the average lifespan of our electrode?

Depending on the application and environment, our electrodes typically last between 3–10 years.

Contact Details

For inquiries and orders for our products, feel free to contact us:

- Name: Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Titanium electrodes are the cornerstone of sustainable and efficient industrial operations. Contact us today to learn more about our products and how they can revolutionize your processes!

YOU MAY LIKE