Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

In industrial electrolysis systems, choosing the right electrode material is critical to achieving high performance, stability, and cost efficiency. Among various electrode materials, the titanium electrode for salt water electrolysis has become one of the most reliable and efficient options for modern industries. With its excellent corrosion resistance, conductivity, and long service life, it is widely used in chlorine generation, seawater electrolysis, wastewater treatment, and hydrogen production.

What Is a Titanium Electrode for Salt Water Electrolysis?

A titanium electrode for salt water electrolysis is a specialized electrochemical component designed for use in saline environments. It serves as an anode or cathode in systems that convert sodium chloride (NaCl) and water into useful chemical products such as chlorine gas, sodium hydroxide, and hydrogen gas.

Technical Parameters of Titanium Electrodes

|

Parameter |

Typical Range |

Description |

|

Substrate Material |

Titanium Grade 1 or Grade 2 |

High-purity base metal |

|

Coating Type |

RuO₂–IrO₂–TiO₂ |

Mixed metal oxide coating |

|

Coating Thickness |

5–20 µm |

Depends on current density |

|

Current Density |

1000–10000 A/m² |

Application-specific |

|

Working Temperature |

≤ 80°C |

Optimal for long-term operation |

|

Service Life |

5–10 years |

Depending on conditions |

|

Shape Available |

Plate, mesh, tube, rod |

Customized upon request |

These parameters may vary based on design requirements, electrolyte composition, and system operating voltage.

How Does a Titanium Electrode Work in Salt Water Electrolysis?

The titanium electrode for salt water electrolysis plays a crucial role in splitting salt water into chemical products through electrochemical reactions.

The Basic Reaction

When an electric current passes through a salt water solution:

-

At the anode (titanium electrode with MMO coating):

2Cl−→Cl2+2e−2Cl^- \rightarrow Cl_2 + 2e^-2Cl−→Cl2+2e−Chlorine gas is generated.

-

At the cathode:

2H2O+2e−→H2+2OH−2H_2O + 2e^- \rightarrow H_2 + 2OH^-2H2O+2e−→H2+2OH−Hydrogen gas and sodium hydroxide (NaOH) are produced.

This process is the foundation for chlor-alkali production, seawater chlorination, and hydrogen generation systems.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key Advantages of Titanium Electrodes for Salt Water Electrolysis

1. Exceptional Corrosion Resistance

Titanium naturally forms a protective oxide layer that resists attack by chlorides and other oxidizing agents in salt water. The addition of MMO coatings further enhances its longevity.

2. High Electrochemical Efficiency

The titanium electrode for salt water electrolysis provides low overpotential and high current efficiency, reducing power consumption and operational costs.

3. Long Service Life

Thanks to the stable MMO or noble metal oxide coatings, these electrodes can operate continuously for 5–10 years depending on current density and operating conditions.

4. Environmentally Friendly

Unlike graphite or lead-based electrodes, titanium electrodes do not contaminate the electrolyte, making them ideal for eco-friendly water treatment and hydrogen generation.

5. Easy Maintenance and Replacement

The electrode’s modular structure allows for quick replacement and maintenance, minimizing system downtime.

Industrial Applications of Titanium Electrodes

The titanium electrode for salt water electrolysis has a wide range of industrial applications across multiple sectors:

1. Chlor-Alkali Industry

Used for the electrolysis of brine to produce chlorine, hydrogen, and sodium hydroxide—the cornerstone of many chemical manufacturing processes.

2. Seawater Chlorination Systems

Applied in marine, desalination, and cooling water systems to generate on-site chlorine for disinfection and biofouling control.

3. Hydrogen Production

In hydrogen generation units, titanium electrodes serve as durable anodes for long-term operation in saline or alkaline electrolytes.

4. Wastewater Treatment

Used for electrochemical oxidation of organic contaminants and electrocoagulation in industrial wastewater treatment systems.

5. Electroplating and Metal Finishing

Ensures consistent current distribution and reduced contamination in electroplating and surface finishing processes.

Titanium Electrodes in Seawater Chlorination Case

In a coastal power plant cooling system, seawater is continuously circulated to remove heat. Biofouling from marine organisms often reduces flow efficiency and causes corrosion.

To address this, the plant adopted an on-site seawater electrolysis system using titanium electrodes coated with Ru–Ir MMO. The system generates sodium hypochlorite (NaOCl) directly from seawater, preventing fouling and corrosion.

Results:

Chlorine concentration: 0.8–1.0 ppm

Energy consumption reduced by 15%

Electrode lifespan exceeded 7 years

This case demonstrates the efficiency, reliability, and environmental benefits of titanium electrodes for salt water electrolysis.

Quality Assurance and Testing Standards

|

|

|

|

|

|

|

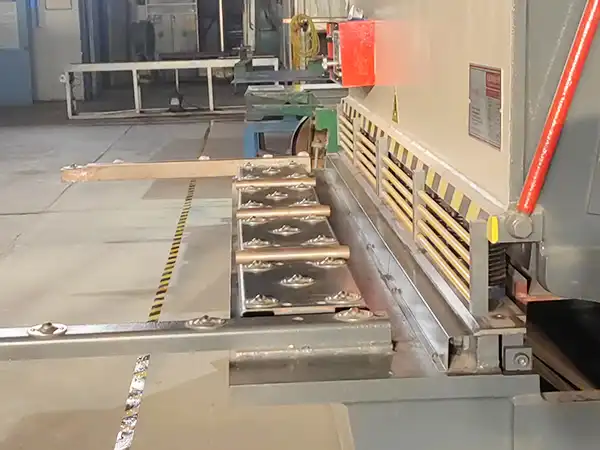

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Research and Innovation

Our team constantly innovates to meet evolving industry needs, offering advanced titanium electrode solutions.

Excellent Reputation

With over 17 years of expertise, we’ve built a trusted brand recognized for quality and reliability.

Striving for Excellence

Adhering to strict quality management, we deliver high-performance products tailored to specific applications.

Customized Services

We offer bespoke solutions to meet unique customer requirements, including size, coating type, and application-specific designs.

Timely Delivery and Support

Our efficient production and logistics systems ensure quick delivery and comprehensive after-sales support.

OEM Services

Partner with us for OEM solutions that are fully tailored to align with your brand and operational goals. We work closely with you to design and manufacture titanium electrode for salt water electrolysis that not only meet your specific technical requirements but also enhance your brand’s identity in the market. From product development and customization to packaging and labeling, our comprehensive approach ensures that each solution is a perfect fit for your needs.

With a strong focus on quality, performance, and innovation, our OEM solutions help you strengthen your market position and drive business success. Let us be your trusted partner in creating high-performance products that reflect your brand’s values and meet the demands of your industry. Reach out today to explore the possibilities!

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1.What is the lifespan of the titanium electrode?

Service life ranges from 3 to 5 years, depending on usage conditions and maintenance practices.

2.Can the electrode be customized?

Yes, we offer tailored solutions for size, coating, and application-specific requirements.

3.What industries use these electrodes?

Applications span water treatment, chemical production, marine industries, and more.

4.How is the electrode shipped?

Our electrodes are carefully packaged to ensure safe transportation and delivered on time worldwide.

Contact Details

Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

We’re ready to meet your needs for high-quality titanium electrode for salt water electrolysis. Contact us today to learn more or request a quote!

YOU MAY LIKE