Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

In the field of electrochemical processes, titanium electrode for electrolysis has become an essential component for achieving efficiency, durability, and environmental sustainability. Known for their superior corrosion resistance, high electrical conductivity, and long service life, titanium electrodes play a vital role in numerous industrial electrolysis applications—from water treatment and metal refining to hydrogen production and electroplating.

What is a Titanium Electrode for Electrolysis?

A titanium electrode for electrolysis is a conductive component made primarily from titanium substrate, coated with active catalytic materials such as ruthenium oxide (RuO₂), iridium oxide (IrO₂), or platinum (Pt). These coatings improve the electrode’s catalytic activity and corrosion resistance, ensuring stable performance even in harsh electrolytic environments.

Technical Parameters of Titanium Electrode for Electrolysis

|

Parameter |

Typical Value |

Description |

|

Substrate Material |

Gr1 / Gr2 Titanium |

High-purity titanium base |

|

Coating Composition |

RuO₂, IrO₂, Ta₂O₅, Pt |

Catalytic and corrosion-resistant coating |

|

Coating Thickness |

3–10 μm |

Depends on application |

|

Current Density |

500–2000 A/m² |

Customizable |

|

Operating Temperature |

≤80°C |

Stable under long-term use |

|

Lifespan |

2–10 years |

Depending on usage and electrolyte type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Using Titanium Electrode for Electrolysis

Choosing a titanium electrode for electrolysis provides several key benefits compared to traditional graphite or steel electrodes.

1. Superior Corrosion Resistance

The noble metal oxide coatings protect the titanium substrate even under aggressive chemical conditions, extending electrode lifespan.

2. High Catalytic Efficiency

The electrode surface maintains a high level of catalytic activity, minimizing voltage drop and reducing energy consumption.

3. Stable Electrochemical Performance

Titanium electrodes exhibit excellent current distribution, ensuring consistent product quality in electrochemical reactions.

4. Low Maintenance Cost

With long service life and minimal degradation, titanium electrodes reduce maintenance frequency and downtime.

5. Customizable Design

Manufacturers can produce titanium electrodes in different shapes—mesh, plate, rod, or tube—based on specific equipment or industry needs.

Application fields of titanium electrodes for electrolysis

1. Water Treatment and Electrochlorination

Titanium electrodes are used in electrochlorination systems to produce sodium hypochlorite from seawater or brine. These systems are essential for:

Disinfecting drinking water

Sterilizing swimming pools

Desalination plants

Marine ballast water treatment

2. Metal Electroplating and Electrorefining

In the electroplating industry, titanium electrodes serve as insoluble anodes, providing uniform current distribution for high-quality metal coatings such as copper, nickel, and chromium.

3. Hydrogen Production by Electrolysis of Water

With the growing demand for green hydrogen, titanium electrodes for electrolysis have become indispensable in alkaline and PEM electrolyzers. Their stability and low overpotential make them ideal for continuous hydrogen generation.

4. Wastewater Treatment

Titanium electrodes are effective for electro-oxidation, COD removal, and decolorization of industrial wastewater. They are especially useful in treating wastewater from:

Textile dyeing

Petrochemical plants

Electroplating factories

5. Electrochemical Synthesis

Used in producing various chemicals (e.g., perchlorates, chlorates, and hypochlorites), titanium electrodes help improve process yield and energy efficiency.

Titanium Electrode for Electrolysis in Action Case

1: Seawater Electrochlorination Plant

A coastal water treatment facility in Southeast Asia adopted Ru-Ir oxide-coated titanium electrodes to generate sodium hypochlorite for sterilization. The system operated continuously for over five years without noticeable degradation, reducing chemical purchase costs by 35%.

2: Hydrogen Production Project

A renewable energy company in Europe implemented Pt-coated titanium electrodes in a proton exchange membrane (PEM) electrolyzer. The system achieved high hydrogen purity (>99.999%) and reduced energy consumption by 20% compared to conventional electrodes.

3: Electroplating Wastewater Treatment

In a Chinese electroplating plant, titanium electrodes for electrolysis were used for COD reduction and metal ion recovery, significantly improving effluent quality and meeting strict environmental discharge standards.

|

|

|

|

|

|

|

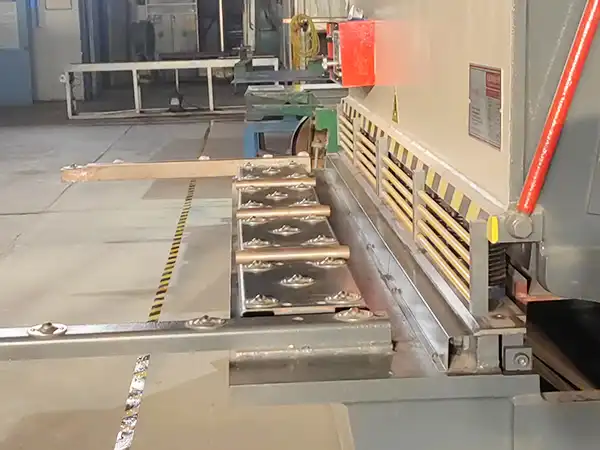

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Titanium Electrode from Baoji City ShenAo Metal Materials Co., Ltd.?

Baoji City ShenAo Metal Materials Co., Ltd. is a leading manufacturer specializing in titanium electrode for electrolysis, DSA-coated titanium anodes, and non-ferrous metal composite materials. With advanced production technology, strict quality control, and global supply capability, ShenAo provides customized electrode solutions for different electrochemical industries.

Our Strengths

Over 15 years of manufacturing experience

In-house coating formulation and testing laboratory

ISO 9001 certified production

Support for OEM/ODM customization

Global export service and technical support

Main Product Lines

Titanium anodes for water treatment

Platinum-coated titanium electrodes

Ruthenium–iridium oxide anodes

MMO (Mixed Metal Oxide) coated electrodes

Titanium-based cathodes and mesh anodes

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: How long do titanium electrodes last in electrolysis?

A: The standard lifespan is over three years, depending on usage and operating conditions.

Q2: Can these electrodes be used in seawater desalination systems?

A: Yes, they are designed to withstand corrosive environments like seawater.

Q3: Are customization options available?

A: Absolutely! We can tailor the size, shape, and coating type to your specific needs.

Contact Details

We are here to meet your needs with the most professional services. With our cutting-edge titanium electrode for electrolysis, you are guaranteed efficiency, reliability, and value for your investment. Designed for optimal performance and longevity, our electrodes provide consistent results, making them the ideal choice for a variety of applications. Let us partner with you to deliver the best solutions tailored to your specific needs. With our expertise and commitment to quality, we ensure that your operations run smoothly and efficiently. Contact us today to learn how we can help elevate your business!

Company: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86 18729731603

Fax: +86 917-3380538

Email: zh@baojiti.com.cn

YOU MAY LIKE