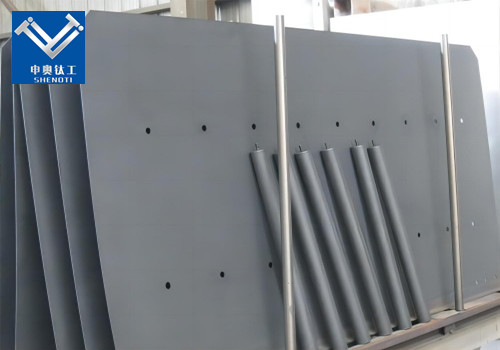

Baoji City ShenAo Metal Accoutrements Co., Ltd., positioned in the heart of China's Titanium Valley, specializes in producing decoration titanium anodes acclimatized to meet client requirements.

Technical Specifications

|

Feature |

Details |

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical Advantages of Titanium Anode Plate

The titanium anode plate provides numerous advantages compared to traditional graphite or lead-based anodes. Its advanced design ensures longer life cycles, higher efficiency, and reduced maintenance costs.

1. Excellent Corrosion Resistance

Titanium is naturally resistant to chemical attack in most acidic and alkaline environments. The oxide coating further enhances this resistance, making the anode ideal for use in harsh conditions such as seawater or acid electrolytes.

2. High Electrochemical Efficiency

The catalytic oxide layer provides a lower overpotential for oxygen and chlorine evolution reactions, resulting in significant energy savings during electrolysis.

3. Dimensional Stability

Unlike traditional anodes that degrade or change shape during operation, the titanium anode plate maintains a consistent geometry, ensuring uniform current distribution and high product quality.

4. Long Service Life

Due to the strong adhesion between the titanium substrate and the oxide coating, the anode’s operational life can exceed 10 years, even under continuous use.

5. Eco-Friendly Performance

The titanium anode plate does not dissolve or release harmful substances during electrolysis, contributing to environmentally friendly industrial processes.

Applications of Titanium Anode Plate in Different Industries

1. Electroplating Industry

In electroplating, the titanium anode plate is used as an inert electrode for metal deposition processes such as chromium, nickel, and copper plating. It ensures stable current density, uniform coating, and reduced impurities in the final product.

2. Wastewater Treatment

In industrial wastewater treatment, the titanium anode plate plays a crucial role in electrochemical oxidation. It effectively degrades organic pollutants, phenols, and cyanides without adding secondary contaminants. This makes it widely used in coking, chemical, and pharmaceutical wastewater purification.

3. Chlor-Alkali Industry

Titanium anode plates coated with ruthenium-iridium oxides are the preferred choice for chlorine generation and sodium hypochlorite production. They provide high chlorine evolution efficiency and excellent stability in brine electrolytes.

4. Electrowinning and Metal Recovery

In copper, nickel, and zinc recovery systems, titanium anode plates ensure efficient current transfer and improve metal purity. They are widely used in hydrometallurgy and electro-refining operations.

5. Water Disinfection Systems

Municipal water treatment plants use titanium anodes for on-site generation of disinfectants like sodium hypochlorite. Their stability ensures safe and reliable disinfection for drinking and pool water systems.

Case : Titanium Anode Plate for Coking Wastewater Treatment

A major steel enterprise in China adopted MMO-coated titanium anode plates for treating high-concentration coking wastewater. The system achieved:

90% reduction in COD (chemical oxygen demand)

70% reduction in ammonia nitrogen

100% elimination of phenolic compounds

Service life exceeding 5 years with stable operation

This successful application demonstrates the durability and cost-effectiveness of titanium anode plates in complex industrial environments.

How to Choose the Right Titanium Anode Plate

When selecting a titanium anode plate, consider the following key factors:

Electrolyte Composition: Determine if the environment is acidic, alkaline, or neutral.

Current Density: Higher current densities require more robust coatings.

Operating Temperature: Ensure the anode’s coating can withstand temperature variations.

Desired Electrochemical Reaction: Choose the appropriate oxide coating for oxygen or chlorine evolution.

Service Life and Maintenance: Evaluate expected operational cycles and replacement intervals.

A professional supplier can customize the coating type, substrate thickness, and structure to match your exact industrial requirements.

|

|

|

|

|

|

|

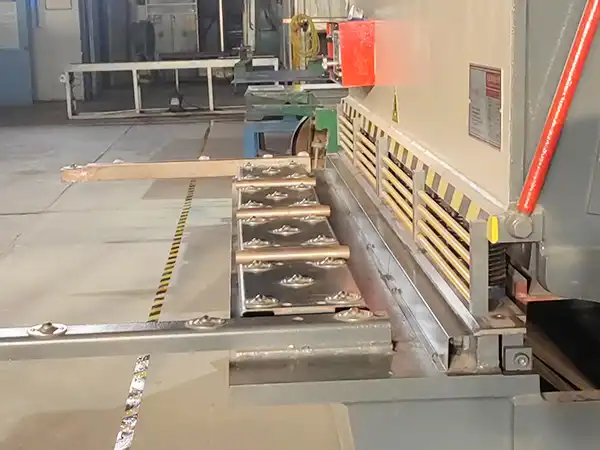

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

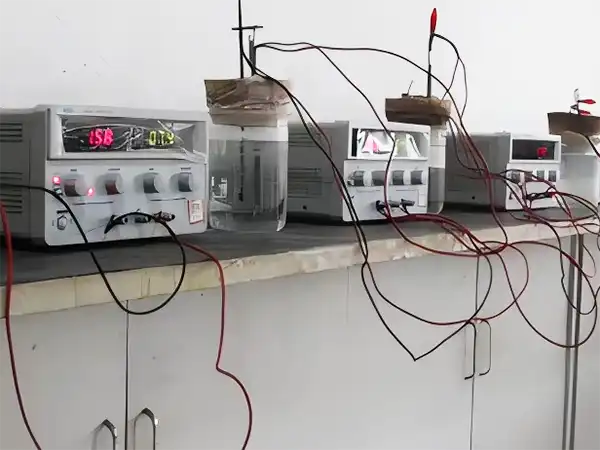

Research and Innovation

With a dedicated R&D team, Baoji City ShenAo Metal Materials Co., Ltd. develops innovative solutions tailored to evolving industry needs.

Excellent Reputation

Backed by 17 years of expertise, our brand is synonymous with quality and reliability.

Striving for Excellence

Strict quality control ensures consistent performance, whether for small-batch orders or large-scale production.

Customized Services

We provide tailor-made solutions to meet specific technical requirements, ensuring customer satisfaction.

Timely Delivery and Robust Support

Our efficient logistics system and responsive customer service ensure seamless transactions and post-sales support.

OEM Services

Comprehensive OEM services feed to unique client demands, making us a one- stop result for our products. From design and product to custom-made packaging and labeling, we insure that every aspect of the product aligns with your specifications and branding conditions. Our moxie in manufacturing high- performance MMO titanium anodes, combined with flexible product capabilities, guarantees that we meet different assiduity requirements, including water treatment, electroplating, and cathodic protection. Whether you need small or large amounts, our acclimatized results give harmonious quality and trustability for your business.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. What is the lifespan of the product?

They are typically last 3–5 years, depending on usage and operating conditions.

2. Can the dimensions and coatings be customized?

Yes, we offer customizable dimensions and a range of coating materials, including platinum, iridium, and ruthenium.

3. Are our products suitable for seawater applications?

Absolutely. Titanium’s corrosion resistance makes it ideal for seawater desalination and marine applications.

Contact Details

We’re then to give expert backing and meet your specific conditions for titanium anode plates. Our platoon of professionals is devoted to offering individualized support, from product selection to specialized guidance, icing that you admit the ideal result for your operations. Whether you are looking for high- performance mixed essence oxide( MMO) anodes for water treatment, electroplating, or cathodic protection, we work nearly with you to understand your requirements and deliver dependable, cost-effective products. With our expansive experience and commitment to quality, you can trust us to be your go- to mate for all your profuct conditions.

Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

E-Mail: zh@baojiti.com.cn

For inquiries or orders, reach out to us today!

YOU MAY LIKE