Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

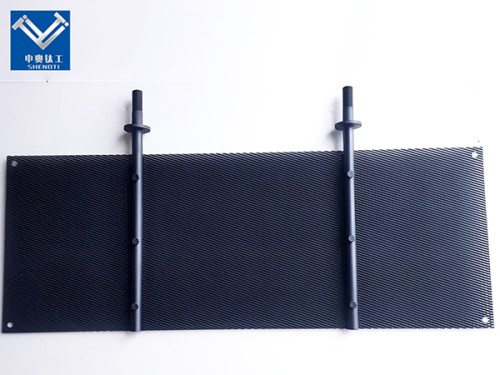

In modern electrochemical industries, the electrolysis titanium electrode plays an essential role in achieving efficient, stable, and long-lasting performance. Known for its superior corrosion resistance, high conductivity, and excellent catalytic properties, this advanced electrode material is widely used in water treatment, metal plating, chlor-alkali production, and various electrolysis processes.

What is an Electrolysis Titanium Electrode?

An electrolysis titanium electrode is a metal electrode made primarily from high-purity titanium, used as the substrate for electrochemical reactions. On its surface, a layer of precious metal oxides—such as ruthenium (Ru), iridium (Ir), platinum (Pt), or mixed metal oxides (MMO)—is coated to enhance catalytic efficiency and stability.

Technical Parameters of Electrolysis Titanium Electrode

|

Parameter |

Typical Range |

|

Substrate Material |

Pure Titanium (Gr1, Gr2) |

|

Coating Composition |

RuO₂, IrO₂, Pt, Ta₂O₅, SnO₂, or mixed oxides |

|

Working Voltage |

1.0 – 3.5 V (depending on application) |

|

Current Density |

Up to 10,000 A/m² |

|

Operating Temperature |

≤ 80°C |

|

Service Life |

2–10 years (application-dependent) |

These parameters can be customized according to the client’s specific process conditions, such as pH level, current density, and electrolyte type.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applications of Electrolysis Titanium Electrode

1. Water Treatment and Electrolytic Disinfection

In wastewater and drinking water treatment, electrolysis titanium electrodes are used for electrochemical oxidation, generating active chlorine or hydroxyl radicals that effectively degrade organic pollutants and disinfect bacteria.

Applications include:

Electrolytic oxidation of industrial wastewater

Swimming pool water disinfection

Electrolyzed water generators

2. Chlor-Alkali and Chemical Production

In the chlor-alkali industry, titanium electrodes for electrolysis are used for producing chlorine, sodium hydroxide, and hydrogen through brine electrolysis. The stable performance and low energy consumption make them essential in modern chemical plants.

3. Metal Electroplating and Surface Finishing

Electrolysis titanium electrodes coated with platinum or iridium are used as insoluble anodes in electroplating processes for metals such as copper, nickel, chromium, and gold.

They maintain a constant anode potential, ensuring uniform metal deposition and improving product quality.

4. Hydrogen Generation by Water Electrolysis

As the hydrogen economy expands, titanium electrolysis electrodes are increasingly adopted in hydrogen production systems. Their high stability and low overpotential enable efficient hydrogen generation with minimal maintenance.

5. Electrolytic Recovery of Metals

In hydrometallurgy, electrolysis titanium electrodes are used to recover valuable metals from solutions—such as copper, nickel, and silver—while reducing environmental pollution and improving resource utilization.

Advantages of Using Electrolysis Titanium Electrode

1. Excellent Corrosion Resistance

Titanium and its oxide coatings resist corrosion from acids, alkalis, and chlorine, ensuring long-term stability in harsh environments.

2. High Electrochemical Efficiency

The mixed metal oxide coating provides high catalytic activity, reducing cell voltage and energy consumption.

3. Long Service Life

Due to the durable coating and stable titanium substrate, the electrolysis titanium electrode can operate for thousands of hours with minimal degradation.

4. Stable Current Distribution

Uniform coating and excellent conductivity ensure even current distribution, improving reaction uniformity and product quality.

5. Environmental Benefits

Unlike graphite or lead-based anodes, titanium electrodes are environmentally friendly and do not introduce heavy metals into the process.

Industry Case Studies

1: Electrochemical Wastewater Treatment in Electronics Manufacturing

A large electronics factory adopted electrolysis titanium electrodes coated with Ru-Ir oxide for its wastewater treatment line.

The results showed:

COD removal efficiency: >90%

Energy consumption: reduced by 20%

Electrode life: extended to 5 years

2: Chlorine Generation for Water Disinfection

A water utility installed a titanium-based electrolytic disinfection system using MMO-coated titanium electrodes. The system continuously generated sodium hypochlorite on-site, lowering chemical transport costs and improving safety.

3: Hydrogen Production by Electrolysis

A renewable energy company deployed titanium-plated electrodes in its PEM electrolyzer system, achieving high purity hydrogen generation with over 85% energy efficiency and low maintenance costs.

|

|

|

|

|

|

|

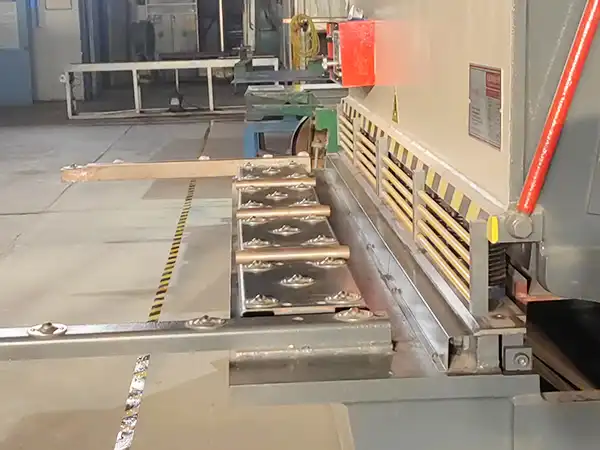

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Our Electrolysis Titanium Electrodes

Our company specializes in the research, design, and production of electrolysis titanium electrodes tailored to various industrial applications.

Key Strengths:

Over 20 years of electrochemical material expertise

Advanced coating technologies with precision thermal treatment

Customized electrode design for specific electrolyte systems

Strict quality control and ISO-certified manufacturing

We offer electrodes with Ru-Ir, Pt, or Ta-Sn oxide coatings, available in mesh, plate, tube, and rod forms according to customer requirements.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What makes your titanium electrodes different?

A: Our electrodes feature premium-grade titanium substrates and innovative coatings, ensuring superior corrosion resistance and performance in harsh environments.

Q2: Can I request custom dimensions or coatings?

A: Absolutely! We provide fully customizable solutions to meet your specific application requirements.

Q3: How do I ensure the longevity of the electrode?

A: Proper maintenance, such as regular cleaning and avoiding overloading, will maximize the electrode’s lifespan.

Contact Us

For inquiries or to place an order, reach out to us directly. Our team is ready to assist you in finding the perfect solution for your electrolysis titanium electrode needs. Whether you're looking for customized titanium electrodes or seeking expert guidance, we're here to help. Contact us today to discuss how we can support your business with high-performance, reliable products tailored to your specific requirements!

Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86 18729731603

Fax: +86 917-3380538

Email: zh@baojiti.com.cn

YOU MAY LIKE