DSA titanium anodes (Dimensionally Stable Anodes) represent a breakthrough in electrochemical technology. They are specialized anodes made from a titanium substrate coated with mixed metal oxides (MMO) such as ruthenium, iridium, or tantalum oxides. The key feature of DSA titanium anodes is their dimensional stability, meaning their size and shape remain constant during electrolysis, even after long periods of operation.

Unlike traditional anodes that degrade quickly or release unwanted impurities, DSA titanium anodes provide excellent corrosion resistance, low energy consumption, and extended service life. These unique characteristics make them ideal for industries that rely on electrochemical processes — including chlor-alkali production, electroplating, wastewater treatment, and electrowinning.

Technical Parameters of DSA Titanium Anodes

|

Parameter |

Typical Value |

|

Substrate Material |

Titanium (Gr1 / Gr2) |

|

Coating Composition |

RuO₂, IrO₂, Ta₂O₅, TiO₂, SnO₂ |

|

Coating Thickness |

2–10 μm |

|

Operating Voltage |

1.2–2.5 V |

|

Current Density |

Up to 10,000 A/m² |

|

Service Life |

5–10 years (depending on use) |

|

Operating Temperature |

Up to 80°C |

|

Electrolyte pH Range |

0–14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of Using DSA Titanium Anodes

1. Extended Lifespan and Durability

The combination of a corrosion-resistant titanium base and a stable MMO coating allows DSA titanium anodes to operate continuously for years without performance degradation.

2. Improved Energy Efficiency

Low oxygen and chlorine overpotential mean that DSA titanium anodes reduce overall cell voltage, leading to lower electricity consumption and reduced operational costs.

3. Environmental and Operational Safety

Unlike traditional lead-based or graphite anodes, DSA titanium anodes do not release toxic substances or heavy metals, ensuring compliance with environmental and safety regulations.

4. Stable Electrochemical Performance

DSA titanium anodes maintain uniform current distribution and constant anode geometry throughout operation, ensuring consistent product quality and process reliability.

Applications of DSA Titanium Anodes Across Industries

Because of their superior electrochemical stability, DSA titanium anodes are widely applied in various industries that depend on reliable and efficient electrolysis systems.

1. Chlor-Alkali Industry

One of the earliest and most significant applications of DSA titanium anodes is in the chlor-alkali process for producing chlorine, hydrogen, and sodium hydroxide. Compared to graphite or lead anodes, DSAs significantly reduce cell voltage and operational costs.

2. Electroplating and Metal Finishing

In electroplating, DSA titanium anodes provide consistent current distribution and prevent contamination of the electrolyte. They are used in plating metals such as copper, nickel, chromium, and gold, ensuring smoother surfaces and superior coating adhesion.

3. Water and Wastewater Treatment

In electrochemical oxidation systems, DSA titanium anodes are used for the degradation of organic pollutants and disinfection. They generate active oxygen species and chlorine radicals to break down contaminants efficiently, making them essential for industrial wastewater treatment and municipal water disinfection.

4. Electrowinning and Metal Recovery

DSA titanium anodes are also crucial in hydrometallurgical processes for recovering metals such as copper, zinc, and manganese. Their stability under harsh electrolytic conditions ensures consistent metal yield and minimal maintenance.

5. Cathodic Protection Systems

In impressed current cathodic protection (ICCP), DSA titanium anodes protect steel structures such as pipelines, tanks, and offshore platforms from corrosion. They provide long-term protection in marine and soil environments.

6. Hypochlorite and Ozone Generation

Another growing application is in the production of sodium hypochlorite and ozone generators. DSA titanium anodes enable efficient electrolysis of seawater or brine solutions, ensuring reliable disinfectant generation for water treatment and sanitation.

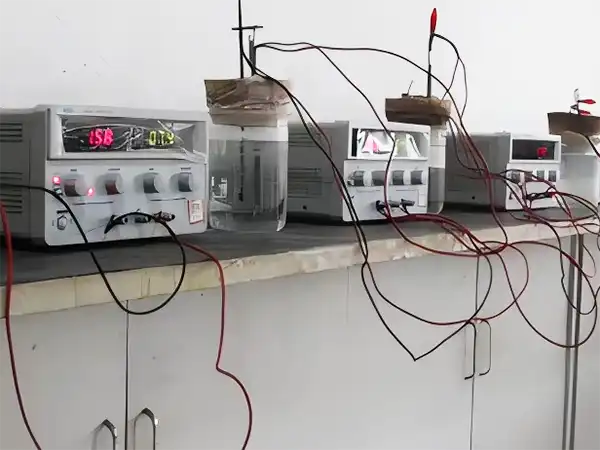

DSA Titanium Anodes in Action Case

1: Wastewater Treatment Plant in Southeast Asia

A municipal treatment facility adopted DSA titanium anodes coated with RuO₂–IrO₂ for electrochemical oxidation. After 18 months of continuous operation, the COD (Chemical Oxygen Demand) of treated water decreased by 85%, with stable anode performance and no significant degradation observed.

2: Chlorine Production in the Middle East

An industrial chlorine producer replaced graphite anodes with DSA titanium anodes. The upgrade reduced power consumption by 20% and increased chlorine yield by 12%, demonstrating superior energy efficiency and process control.

3: Cathodic Protection for Offshore Pipelines

For a deep-sea oil pipeline network, DSA titanium anodes with MMO coatings were used in ICCP systems. The system provided over 15 years of maintenance-free corrosion protection, outperforming traditional sacrificial anodes.

|

|

|

|

|

|

|

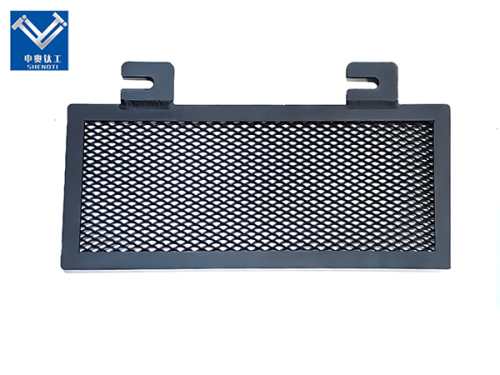

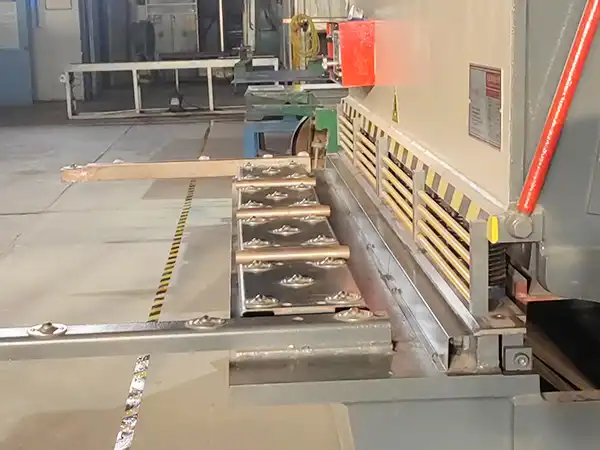

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Research and Innovation

With an experienced R&D team, Baoji City ShenAo Metal Materials Co., Ltd is at the forefront of anode technology, continuously enhancing product performance to meet evolving industrial needs.

Excellent Reputation

17 years of delivering top-quality products have earned us trust and recognition from global clients in various industries.

Striving for Excellence

Our stringent quality control processes ensure every product meets high standards, whether for small-batch testing or large-scale production.

Customization Services

We tailor our products to specific customer needs, offering diverse specifications and configurations for various applications.

Reliable Support

Timely delivery and a customer-focused after-sales service ensure a seamless experience from order to implementation.

OEM Services

Our OEM capabilities empower us to deliver customized arrangements beneath your brand, giving you a competitive edge in the showcase. With our mastery in fabricating high-quality titanium anodes, we offer adaptable alternatives in plan, fabric choice, and execution highlights to meet your particular prerequisites. From personalized bundling and labeling to exact specialized details, we guarantee that your items stand out and provide remarkable comes about. By collaborating with us, you can offer custom-made arrangements that not as it were meet industry guidelines but too improve your brand's notoriety for development and quality.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What are Titanium Anodes used for?

A: They are used in applications such as electroplating, seawater desalination, and wastewater treatment.

Q2: How long do last?

A: Depending on the coating and operating conditions, they last 3 to 10 years.

Q3: Can the anodes be customized?

A: Yes, we offer customization in terms of size, coating type, and shape.

Contact Us

We are here to give master arrangements custom fitted to your needs, guaranteeing that you get the best conceivable results for your ventures. Our group is devoted to understanding your particular necessities and advertising personalized back each step of the way. Whether you're looking for high-performance titanium anodes for specialized applications or require help with custom plans, we use our industry skill and progressed innovation to provide solid, productive arrangements that adjust with your targets. Believe us to be your accomplice in accomplishing ideal comes about for your trade. If you want get more information about DSA Titanium Anodes, please at:

Company: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

YOU MAY LIKE