In the modern industrial landscape, customized titanium anodes have become an essential component for a wide range of electrochemical processes. As industries increasingly demand higher efficiency, corrosion resistance, and sustainability, titanium anodes—especially those tailored to specific needs—stand out as the preferred choice. Whether it is for electroplating, wastewater treatment, chlor-alkali production, or cathodic protection, a customized titanium anode ensures maximum performance, longevity, and cost-effectiveness.

What Is a Customized Titanium Anode?

A customized titanium anode is an electrochemical anode manufactured from high-purity titanium as a substrate, coated with a layer of precious metal oxides such as ruthenium, iridium, platinum, or mixed metal oxides (MMO). Unlike standard anodes, these products are custom-engineered based on the specific requirements of the customer, including size, coating type, current density, and operating environment.

Core Structure and Materials

The substrate is typically made of Grade 1 or Grade 2 titanium, known for its excellent corrosion resistance and conductivity. The coating layer, composed of RuO₂, IrO₂, Pt, or Ta₂O₅, provides catalytic activity and determines the anode’s electrochemical characteristics. By adjusting the coating composition and thickness, the customized titanium anode can achieve the desired balance between efficiency and durability.

Why Customization Matters

Different electrochemical applications have unique operating parameters—such as electrolyte composition, temperature, current load, and pH value. Off-the-shelf anodes may not meet these diverse conditions. A customized titanium anode allows for precise optimization of:

Coating type and loading

Surface area and geometry

Electrical connection method

Mechanical support design

Through customization, clients gain a perfectly matched solution that enhances system efficiency and reduces maintenance costs.

Manufacturing Process of Customized Titanium Anodes

Producing a customized titanium anode is a complex and precise process that integrates materials science, electrochemistry, and mechanical engineering. The following stages illustrate how a high-performance anode is made:

1. Titanium Substrate Preparation

The process begins with high-purity titanium sheets, rods, or meshes. The substrate undergoes acid pickling, sandblasting, and ultrasonic cleaning to remove surface oxides and impurities. This step ensures strong adhesion between the titanium substrate and the catalytic coating.

2. Coating Formulation and Application

Depending on the required electrochemical function, coatings are formulated from ruthenium, iridium, platinum, or mixed metal oxides. Using techniques such as thermal decomposition or brush coating, multiple layers are evenly applied to the titanium substrate. Each layer is carefully dried and baked at high temperatures to create a firm, adherent surface.

3. Thermal Treatment

After coating, the anode undergoes multiple thermal cycles in an electric furnace. The precise temperature control ensures uniform crystal structure formation, which directly affects the electrocatalytic performance and lifespan of the customized titanium anode.

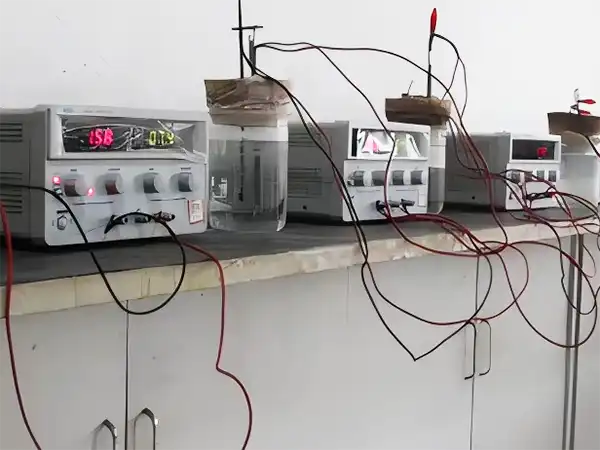

4. Quality Inspection and Testing

Every customized titanium anode is subjected to rigorous quality testing. Standard tests include:

Adhesion and coating integrity checks

Electrochemical performance testing

Accelerated life testing under simulated operating conditions

These steps guarantee consistent quality and reliability before the product is delivered to clients.

Types of Customized Titanium Anodes

The versatility of titanium allows for numerous structural and coating variations. Some common configurations include:

1. MMO (Mixed Metal Oxide) Titanium Anode

Widely used for water treatment and cathodic protection, the MMO-coated titanium anode features a Ru-Ir oxide layer that offers long service life and low chlorine evolution potential.

2. Platinum-Coated Titanium Anode

With excellent conductivity and catalytic activity, the platinum-coated titanium anode is ideal for electroplating and electrolytic refining of precious metals.

3. Ruthenium-Iridium Titanium Anode

This type provides superior chlorine and oxygen evolution performance, making it suitable for chlor-alkali and seawater electrolysis.

4. Lead Dioxide-Coated Titanium Anode

Used in organic synthesis and wastewater oxidation, this anode provides high oxygen overpotential, enabling deep oxidation reactions.

Each type can be further customized in geometry—plate, mesh, rod, or tubular form—to fit different equipment designs.

Technical Parameters of Customized Titanium Anodes

|

Parameter |

Typical Range |

|

Substrate Material |

Gr1 / Gr2 Titanium |

|

Coating Composition |

RuO₂, IrO₂, Pt, Ta₂O₅, PbO₂ |

|

Current Density |

1000 – 10,000 A/m² |

|

Operating Temperature |

0°C – 80°C |

|

Service Life |

5 – 25 years depending on coating |

|

Shape |

Plate, Mesh, Rod, Tube, Custom Design |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applications of Customized Titanium Anodes

The broad functionality of customized titanium anodes allows them to serve across multiple industries and environments. Here are some key application fields:

1. Electroplating Industry

Customized titanium anodes are used in gold, copper, nickel, and chromium plating processes. Their stable potential and uniform current distribution ensure smooth, bright plating finishes while reducing anode replacement frequency.

2. Wastewater Treatment

In the field of industrial wastewater treatment, titanium anodes coated with MMO or PbO₂ efficiently degrade organic pollutants, heavy metals, and cyanide compounds through electrochemical oxidation. This approach offers an environmentally friendly solution without chemical additives.

3. Chlor-Alkali and Chemical Production

A customized titanium anode designed for chlor-alkali production enhances chlorine evolution efficiency while minimizing energy consumption and by-products. It’s also widely used in electrolytic synthesis of sodium hypochlorite and other chemical compounds.

4. Cathodic Protection Systems

MMO-coated customized titanium anodes are essential for protecting pipelines, offshore platforms, and storage tanks from corrosion. They offer a long operational life in both seawater and soil environments.

5. Energy and New Materials

In emerging industries such as hydrogen generation, fuel cells, and lithium battery recycling, customized titanium anodes play a key role in ensuring efficient and stable electrochemical reactions.

Advantages of Using Customized Titanium Anodes

Choosing a customized titanium anode over conventional electrodes delivers several benefits:

Superior Corrosion Resistance

Titanium naturally forms a stable oxide film, providing unmatched resistance to corrosion in acid, alkali, and salt solutions.

Extended Service Life

Coatings such as Ru-Ir and Pt can sustain long-term electrochemical reactions without significant performance loss, reducing downtime and maintenance.

High Current Efficiency

Customized coating formulas enhance catalytic activity, ensuring maximum current utilization and lower energy costs.

Design Flexibility

Whether in plate, mesh, or tubular shape, a customized titanium anode can be engineered to fit any reactor or electrolytic cell design.

Environmental Sustainability

Unlike traditional graphite or lead anodes, titanium anodes do not dissolve or pollute the electrolyte, aligning with modern environmental standards.

Customized Titanium Anodes Case

1: Electroplating Plant in Southeast Asia

A nickel plating factory required an anode that could withstand high chloride concentration and continuous operation. By developing a customized titanium anode with a Ru-Ir oxide coating, the plant extended anode lifespan by 40% and reduced energy consumption by 15%.

2: Wastewater Treatment Project in Europe

For a chemical wastewater treatment system, a PbO₂-coated titanium anode was customized to handle strong organic pollutants. The system achieved a 98% removal rate of COD and operated stably for over two years without coating degradation.

3: Offshore Cathodic Protection in the Middle East

A large offshore oil company adopted MMO tubular titanium anodes for cathodic protection. The anodes were customized for high salinity conditions, resulting in a maintenance-free service life exceeding 25 years.

|

|

|

|

|

|

|

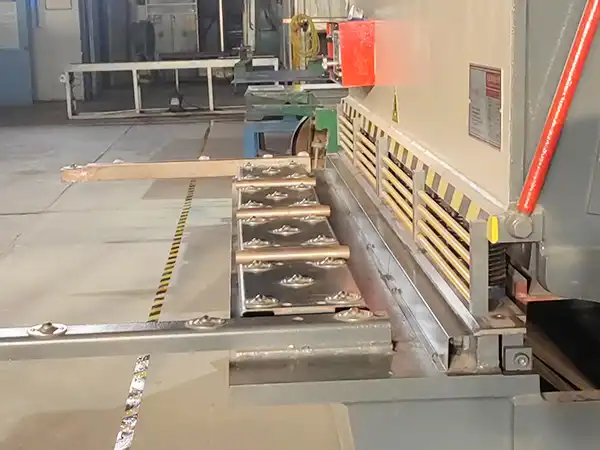

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

In today’s competitive industrial environment, customized titanium anodes have become indispensable for achieving high performance, cost efficiency, and environmental compliance. Their flexibility in design, superior corrosion resistance, and long-term stability make them ideal for a variety of electrochemical systems.

Whether your business operates in electroplating, wastewater treatment, or chemical manufacturing, a customized titanium anode designed to your specifications can deliver measurable improvements in productivity and sustainability.

OEM Services

We give complete OEM services for titanium anodes, including design, manufacturing, and packaging, acclimatized to meet your unique requirements. From original conception to final product, we work nearly with you to insure that every aspect of the titanium anodes aligns with your branding and performance specifications. Whether you bear custom-made sizes, coatings, or labeling, our educated platoon is devoted to delivering high- quality results that meet assiduity norms. unite with us to produce products that not only perform optimally but also reflect your brand’s identity, enhancing your request presence and client satisfaction.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What coatings are available for titanium anodes?

A1: We offer coatings such as ruthenium, iridium, platinum, and mixed metal oxides.

Q2: Can I customize the dimensions of the anodes?

A2: Yes, we provide fully customized dimensions to match your specific needs.

Q3: How long is the service life of your titanium anodes?

A3: Depending on the application and operating conditions, our anodes last between 2 to 10 years.

Contact Us

We’re here to provide you with the most professional service. Contact us today to discuss your requirements!

Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

Boost your operations with customized titanium anodes from Baoji City ShenAo Metal Materials Co., Ltd. — a trusted name in innovation and quality. Let’s work together to meet your needs!

YOU MAY LIKE