Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

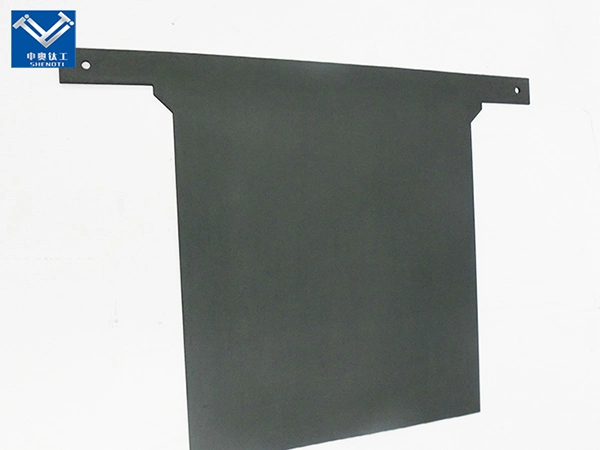

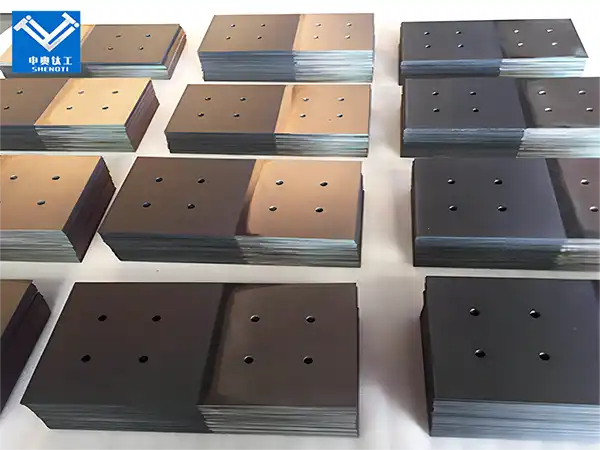

Customizable sizes for various industrial applications.

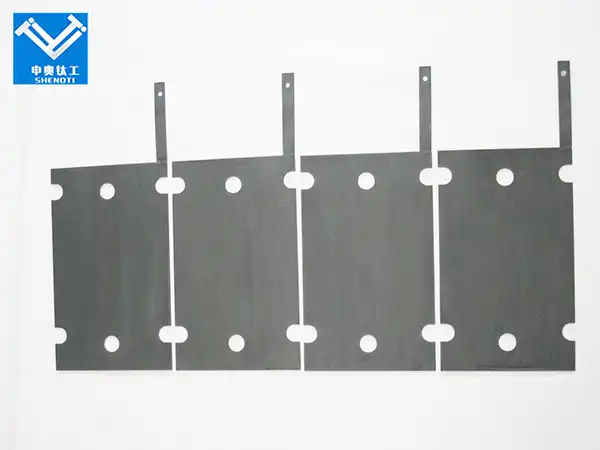

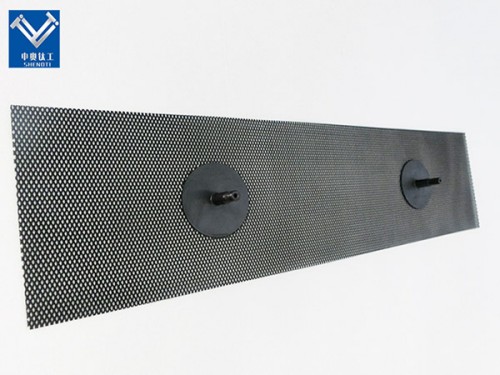

MMO Coated Titanium Anodes for Cathodic Protection Introduction

MMO coated titanium anodes for cathodic protection are advanced electrodes designed for cathodic protection systems. These anodes are essential in preventing corrosion in a variety of industries, from marine to energy and environmental sectors. They provide long-lasting protection to metal structures by emitting current that mitigates the effects of corrosion. Titanium’s inherent corrosion resistance, combined with the efficient MMO (Mixed Metal Oxide) coating, makes these anodes an ideal solution for harsh environments. Whether you're protecting pipelines, ships, or offshore structures, MMO coated titanium anodes ensure reliability and efficiency.

At Baoji City ShenAo Metal Materials Co., Ltd., we specialize in producing high-quality MMO coated titanium anodes that cater to your specific needs. Our products are manufactured using cutting-edge technology, ensuring superior performance and longevity in all cathodic protection applications.

MMO Coated Titanium Anodes for Cathodic Protection Technical Specifications

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

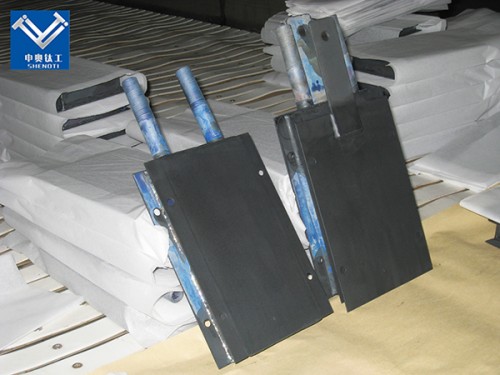

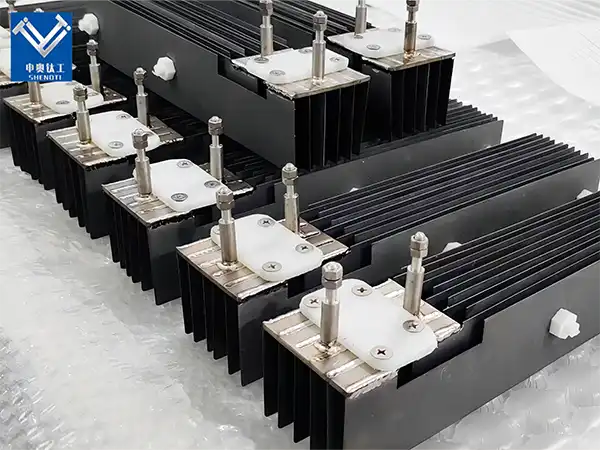

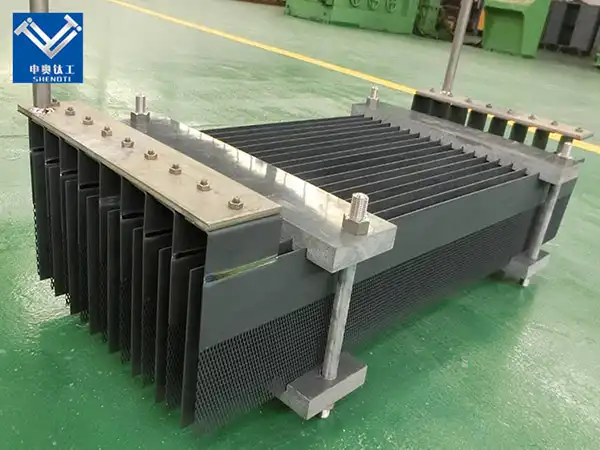

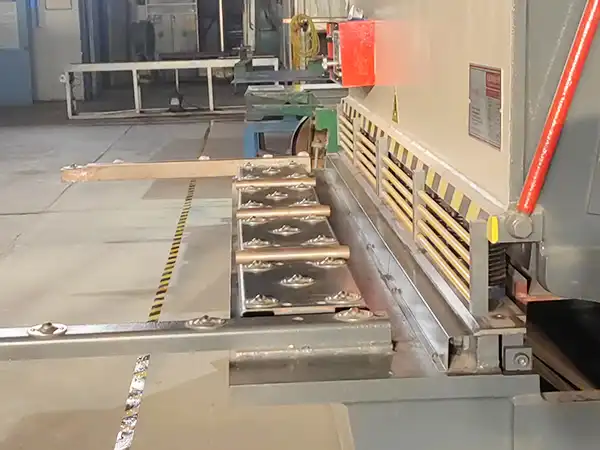

Manufacturing Process of MMO Coated Titanium Anodes

The production of MMO coated titanium anodes for cathodic protection requires advanced metallurgical and coating technologies to guarantee quality and performance.

1: Titanium Substrate Preparation

High-grade titanium sheets, rods, or wires are carefully selected and prepared. The titanium surface undergoes mechanical polishing and chemical cleaning to remove oxides and impurities.

2: Coating Application

A specially formulated slurry of mixed metal oxides is applied to the titanium substrate. This coating may include iridium oxide (IrO₂), ruthenium oxide (RuO₂), or other noble metal oxides depending on the application requirements.

3: Heat Treatment

The coated titanium is subjected to controlled heat treatment cycles. This process bonds the MMO layer to the titanium substrate, enhancing adhesion, conductivity, and durability.

4: Quality Control

Each batch undergoes rigorous inspection, including thickness measurement, surface bonding tests, and electrochemical performance evaluation to ensure consistent quality.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of MMO Coated Titanium Anodes for Cathodic Protection

1. Longevity and Reliability

With service lives exceeding 20 years, these anodes offer long-term protection with minimal maintenance.

2. Cost Effectiveness

Though initial investment may be higher than traditional anodes, the extended life and reduced maintenance make MMO coated titanium anodes for cathodic protection more economical in the long run.

3. High Efficiency

Their excellent electrochemical activity ensures efficient cathodic protection, reducing energy consumption.

4. Versatility

They are adaptable to multiple industries and can be customized in various shapes and sizes to meet specific project needs.

5.Safety and Sustainability

Unlike consumable anodes such as magnesium or zinc, MMO titanium anodes produce minimal by-products, making them environmentally sustainable.

Industry Applications of MMO Coated Titanium Anodes for Cathodic Protection

1. Oil and Gas Industry

In oil and gas, corrosion control is essential for pipelines, offshore platforms, and subsea equipment. MMO coated titanium anodes provide reliable cathodic protection for buried pipelines and marine installations, preventing costly failures.

2. Marine Structures

Ship hulls, harbors, jetties, and seawater intake structures are constantly exposed to saline conditions. MMO coated titanium anodes are highly effective in extending their operational life.

3. Storage Tanks

Above-ground and underground storage tanks are susceptible to corrosion at soil interfaces and water bottoms. Using MMO coated titanium anodes for cathodic protection ensures safety and structural integrity.

4. Reinforced Concrete Structures

Bridges, tunnels, and parking garages reinforced with steel rebar often suffer from chloride-induced corrosion. MMO anodes embedded in concrete prevent rebar degradation and prolong infrastructure lifespan.

5. Power Generation

Cooling water systems, condensers, and intake structures in power plants benefit from MMO titanium anodes to reduce corrosion and maintenance costs.

MMO Coated Titanium Anodes for Cathodic Protection Application Case

1. Offshore Oil Platform Protection

A major offshore oil platform in the Middle East adopted MMO coated titanium anodes for cathodic protection. The anodes demonstrated excellent stability under high salinity conditions, reducing downtime and extending platform service life by decades.

2. Bridge Rehabilitation

A coastal highway bridge experienced severe rebar corrosion due to chloride intrusion. By embedding MMO coated titanium mesh anodes into the concrete, engineers restored the structure and ensured long-term durability with minimal maintenance.

3. Pipeline Cathodic Protection

A natural gas company installed MMO coated titanium tubular anodes along a buried pipeline network. The installation significantly reduced corrosion rates and operational risks, ensuring reliable energy distribution.

|

|

|

|

|

|

|

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

1. Research and Innovation

Baoji City ShenAo Metal Materials Co., Ltd. boasts a professional technical R&D team dedicated to exploring new technologies and improving existing processes. We constantly update our products based on customer needs and market trends.

2. Excellent Reputation

With 17 years of experience, we’ve built a strong reputation for producing high-quality products. Our MMO coated titanium anodes for cathodic protection are trusted by clients worldwide, from the oil and gas industry to marine applications.

3. Striving for Excellence

Our commitment to quality and continuous improvement is reflected in our rigorous production processes. We ensure that each product meets the highest industry standards, from small-scale orders to large-volume deliveries.

4. Customized Product Services

We offer tailored solutions based on your specific requirements, including custom sizes and coatings for titanium anodes and other non-ferrous metal products.

5. Timely Delivery & After-Sales Service

We prioritize customer satisfaction by providing fast delivery and responsive after-sales support, ensuring you receive the assistance you need when you need it.

6. OEM Services

Our experienced team can work with you on custom OEM projects, ensuring that your cathodic protection system works optimally with our tailored anode solutions.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

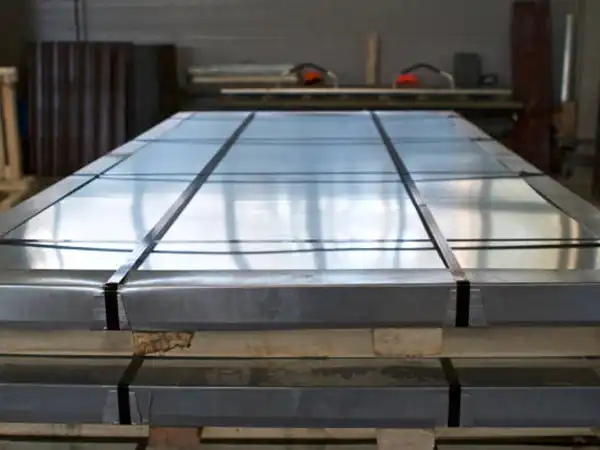

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. What is MMO coated titanium anode?

An MMO coated titanium anode is a corrosion-resistant electrode used in cathodic protection systems. It is coated with mixed metal oxide (MMO) to enhance its efficiency and durability, providing protection against corrosion in various industries.

2. What are the benefits of MMO coated titanium anodes?

MMO coated titanium anodes offer longer service life, high efficiency, and minimal maintenance. They also provide excellent corrosion resistance, especially in harsh environments like seawater and chemical processing.

3. How long do MMO coated titanium anodes last?

The lifespan of MMO coated titanium anodes can range from 15 to 25 years, depending on environmental conditions and maintenance.

4. Can I customize the size and coating of the anodes?

Yes, we offer custom-sized MMO coated titanium anodes with different coating compositions tailored to your specific needs and application requirements.

5. How do I install MMO coated titanium anodes?

MMO coated titanium anodes can be installed in various configurations, such as fixed, flexible, or suspended, depending on your specific application.

Contact Us

If you’re looking for reliable MMO coated titanium anodes for cathodic protection, reach out to us at Baoji City ShenAo Metal Materials Co., Ltd. Our team is ready to provide expert guidance and solutions for your needs.

Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City, Shaanxi, China

Contact: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

E-mail: zh@baojiti.com.cn

We provide the most professional service and look forward to supporting your business needs.

YOU MAY LIKE

_1735356385558.webp)