What Industries Are Tantalum-Copper Composite Plates Mainly Used In?

2025-04-21T02:07:29.000Z

What Industries Are Tantalum-Copper Composite Plates Mainly Used In?

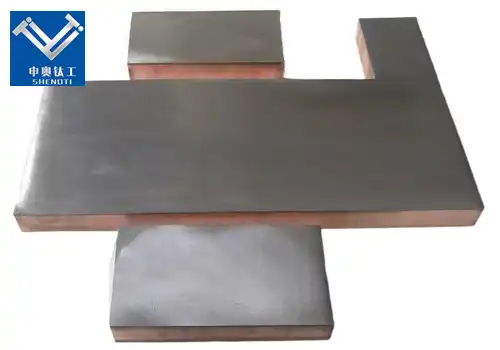

Tantalum-copper composite plates, also known as tantalum clad plates, are engineered materials that combine the corrosion resistance of tantalum with the thermal and electrical conductivity of copper. This unique combination makes them indispensable in various high-performance industrial applications.

What Are the Main Applications of Tantalum-Copper Composite Plates?

Tantalum-copper composite plates are primarily used in industries where materials are exposed to extreme conditions, such as high temperatures, corrosive environments, and the need for excellent thermal and electrical conductivity. Key applications include:

Chemical Processing Industry

In the chemical industry, equipment often encounters highly corrosive substances. Tantalum's exceptional corrosion resistance makes it ideal for lining reactors, heat exchangers, and piping systems. When bonded with copper, the composite plates offer enhanced thermal conductivity, improving heat transfer efficiency in processes like sulfuric acid production and other aggressive chemical reactions .

Electronics and Semiconductor Industry

The electronics industry benefits from the high thermal and electrical conductivity of copper, combined with tantalum's stability and resistance to oxidation. Tantalum-copper composite plates are used in components such as heat sinks, circuit boards, and connectors, where efficient heat dissipation and electrical performance are critical .

Aerospace and Defense Industry

In aerospace applications, materials must withstand extreme temperatures and corrosive environments. Tantalum-copper composites are utilized in components like heat shields, propulsion systems, and structural parts, offering durability and performance under challenging conditions

Medical Industry

The biocompatibility of tantalum makes it suitable for medical implants and devices. When combined with copper's conductivity, these composites are used in medical equipment that requires both compatibility with the human body and efficient electrical performance, such as in certain diagnostic and therapeutic devices

Nuclear and Energy Sector

Tantalum's resistance to radiation and high temperatures makes tantalum-copper composites valuable in nuclear reactors and energy systems. They are used in components that require long-term stability under radiation exposure and thermal stress

How Do Tantalum-Copper Composite Plates Compare to Other Materials?

Compared to other materials, tantalum-copper composites offer a unique combination of properties:

Corrosion Resistance: Superior to many metals, including stainless steel and titanium, especially in acidic environments.

Thermal Conductivity: Enhanced by the copper layer, making them suitable for heat exchangers and thermal management systems.

Mechanical Strength: The composite structure provides strength and durability, essential for structural components in aerospace and defense.

Biocompatibility: Tantalum's compatibility with biological tissues makes these composites ideal for medical applications.

These advantages make tantalum-copper composites a preferred choice in applications where other materials may fail due to corrosion, thermal stress, or biocompatibility issues.

What Are the Manufacturing Methods for Tantalum-Copper Composite Plates?

The production of tantalum-copper composite plates involves advanced metallurgical techniques to ensure a strong bond between the two metals. Common methods include:

Explosive Bonding: A process where controlled explosions are used to bond tantalum to copper, creating a metallurgical bond without melting the metals.

Roll Bonding: Involves rolling the metals together under high pressure and temperature to achieve bonding.

Diffusion Bonding: A solid-state process where metals are joined by applying heat and pressure over time, allowing atoms to diffuse across the interface.

Each method has its advantages, and the choice depends on the intended application, required bond strength, and production considerations.

What Are the Challenges in Using Tantalum-Copper Composite Plates?

While tantalum-copper composites offer numerous benefits, they also present challenges:

Cost: Tantalum is a rare and expensive metal, making the composites costly compared to other materials.

Fabrication Complexity: The bonding processes require specialized equipment and expertise, potentially limiting widespread adoption.

Material Availability: Limited sources of tantalum can affect supply chains and lead times.

Addressing these challenges involves optimizing manufacturing processes, recycling materials, and developing alternative bonding techniques to reduce costs and improve accessibility.

Contact Us

For more information on tantalum-copper composite plates and their applications, please contact us:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with product inquiries, technical support, and customized solutions to meet your specific needs.