What Industries Are Tantalum-Steel Composite Plates Mainly Used In?

2025-04-21T02:38:40.000Z

What Industries Are Tantalum-Steel Composite Plates Mainly Used In?

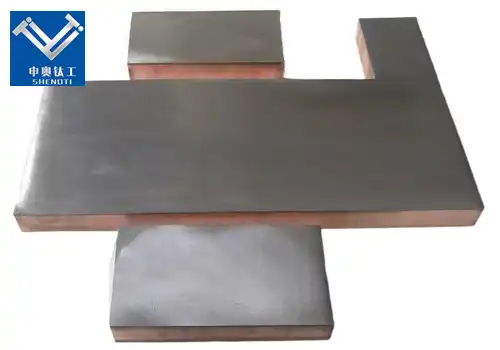

Tantalum-steel composite plates, also known as tantalum clad plates, are engineered materials that combine the superior corrosion resistance of tantalum with the structural strength of steel. This synergy results in a material capable of withstanding extreme environments, making it indispensable across various high-demand industries.

What Are the Advantages of Using Tantalum-Steel Composite Plates Compared to Other Materials?

Tantalum-steel composite plates offer a unique combination of properties that set them apart from other materials:

Exceptional Corrosion Resistance: Tantalum exhibits remarkable resistance to a wide range of corrosive environments, including strong acids like hydrochloric, sulfuric, and nitric acids. This makes tantalum-steel composites ideal for applications in chemical processing industries.

High-Temperature Stability: With a melting point of approximately 3,017°C, tantalum maintains its structural integrity at elevated temperatures, making it suitable for high-temperature applications such as aerospace components and heat exchangers.

Mechanical Strength: The steel substrate provides the necessary mechanical strength and structural support, allowing the composite plate to withstand mechanical stresses while benefiting from the corrosion resistance of tantalum.

Cost-Effectiveness: By cladding a thin layer of tantalum onto a steel substrate, manufacturers can achieve the desired corrosion resistance at a fraction of the cost of using solid tantalum components.

What Are the Technical Specifications and Standards for Tantalum-Steel Composite Plates?

Tantalum-steel composite plates are manufactured to meet specific technical standards to ensure their performance and reliability:

Base Material: Commonly used steel grades include SA-516 Gr.70 or SA-285 Gr.C, providing the necessary mechanical strength.

Cladding Material: Tantalum Grade ASTM B708 R05200 is typically used for the cladding, offering high purity (≥99.9%) and excellent corrosion resistance.

Thickness: Steel substrate thickness ranges from 6mm to 50mm, while the tantalum cladding thickness typically ranges from 0.5mm to 3mm.

Bond Strength: The bond between the tantalum and steel layers must meet or exceed 140 MPa, ensuring structural integrity under operational conditions.

Testing Requirements: Comprehensive testing, including ultrasonic testing of the bond area, dye penetrant testing of exposed edges, bend tests, and shear tests, are conducted to ensure quality and performance.

What Are the Applications of Tantalum-Steel Composite Plates in Various Industries?

Tantalum-steel composite plates find applications across multiple industries due to their unique properties:

Chemical Processing Industry

In the chemical industry, equipment is often exposed to highly corrosive substances. Tantalum-steel composite plates are used to manufacture reactors, heat exchangers, and piping systems that can withstand aggressive chemical environments, thereby enhancing equipment longevity and safety.

Aerospace Industry

The aerospace sector demands materials that can endure extreme temperatures and corrosive conditions. Tantalum-steel composites are utilized in manufacturing components such as jet engine parts and airframe structures, where high-temperature stability and corrosion resistance are critical.

Medical Industry

Due to its biocompatibility and resistance to bodily fluids, tantalum is used in medical implants and surgical instruments. The composite plates provide the necessary strength and corrosion resistance required for long-term implantation and repeated sterilization processes.

Electronics Industry

Tantalum's excellent conductivity and stability make it ideal for electronic components. Tantalum-steel composites are used in the production of capacitors and resistors, which are essential in various electronic devices, including smartphones and computers.

Defense Industry

In defense applications, the high density and strength of tantalum contribute to the effectiveness of armor-piercing projectiles and other military hardware. Tantalum-steel composites are used in the construction of such equipment to enhance performance and durability.

Contact Us

For more information on tantalum-steel composite plates or to discuss your specific requirements, please contact us:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with high-quality materials and tailored solutions to meet your industrial needs.