What are the primary applications of nickel clad plates?

2025-04-18T08:01:04.000Z

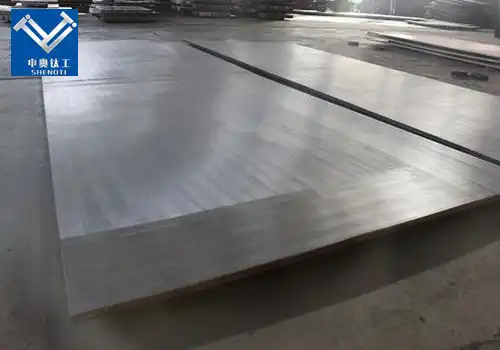

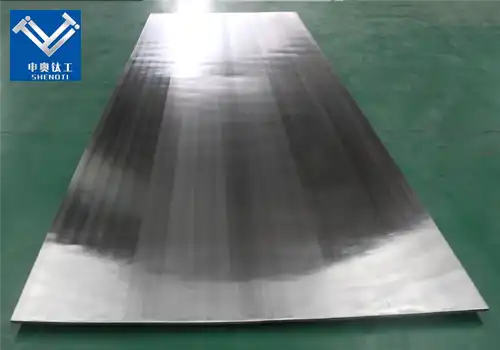

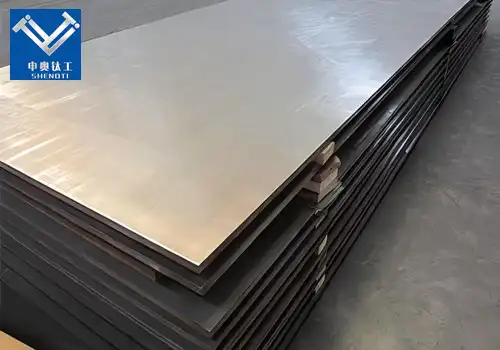

Nickel steel composite plates, commonly known as nickel clad plates, are engineered materials that combine the strength of steel with the corrosion resistance of nickel. These plates are created by bonding a layer of nickel onto a steel substrate, resulting in a material that offers both durability and resistance to harsh environments. This unique combination makes nickel clad plates suitable for a wide range of industrial applications, including chemical processing, power generation, marine engineering, and more.

What are the primary applications of nickel clad plates?

How do nickel clad plates enhance corrosion resistance in industrial settings?

What are the advantages of using nickel clad plates over other materials?

Advantages and uses of nickel-based cladding plates in modern industry.

What Are the Primary Applications of Nickel Clad Plates?

Nickel clad plates are utilized across various industries due to their exceptional properties. Here are some of the primary applications:

1. Chemical Processing Industry

In chemical processing plants, equipment is often exposed to corrosive substances such as acids and alkalis. Nickel clad plates are ideal for constructing reactors, heat exchangers, and storage tanks in these environments. The nickel layer provides excellent resistance to corrosion, ensuring the longevity and safety of the equipment.

2. Power Generation

Power plants, including nuclear and fossil fuel facilities, require materials that can withstand high temperatures and corrosive conditions. Nickel clad plates are used in components like boilers, condensers, and steam generators. Their ability to resist oxidation and maintain structural integrity under extreme conditions makes them a preferred choice.

3. Marine Engineering

Marine environments are notoriously harsh, with equipment constantly exposed to saltwater and varying temperatures. Nickel clad plates are employed in shipbuilding and offshore structures to enhance resistance to seawater corrosion. They are used in hulls, pipelines, and other critical components.

4. Oil and Gas Industry

In the oil and gas sector, materials must endure aggressive chemicals and high-pressure conditions. Nickel clad plates are used in the construction of pressure vessels, separators, and pipelines. Their corrosion resistance ensures operational safety and reduces maintenance costs.

5. Food and Beverage Industry

Hygiene and corrosion resistance are paramount in the food and beverage industry. Nickel clad plates are used in equipment such as storage tanks and processing vessels, where they prevent contamination and withstand cleaning agents.

How Do Nickel Clad Plates Enhance Corrosion Resistance in Industrial Settings?

Corrosion is a significant concern in many industrial applications, leading to equipment failure and safety hazards. Nickel clad plates offer superior corrosion resistance through several mechanisms:

1. Protective Oxide Layer

Nickel naturally forms a thin, adherent oxide layer when exposed to air. This layer acts as a barrier, preventing further oxidation and corrosion. In nickel clad plates, this property protects the underlying steel substrate from corrosive environments.

2. Barrier Protection

The nickel layer serves as a physical barrier, isolating the steel core from corrosive substances. This barrier prevents direct contact between the steel and aggressive chemicals, significantly reducing the rate of corrosion.

3. Galvanic Protection

In certain environments, if the nickel layer is damaged, it can still offer galvanic protection to the steel substrate. Nickel acts as a sacrificial anode, corroding preferentially to protect the steel.

4. Resistance to Specific Chemicals

Nickel exhibits excellent resistance to a variety of chemicals, including:

Sulfuric acid

Hydrochloric acid

Caustic soda

Seawater

This resistance makes nickel clad plates suitable for environments where exposure to these substances is common.

What Are the Advantages of Using Nickel Clad Plates Over Other Materials?

Nickel clad plates offer several benefits compared to traditional materials:

1. Cost-Effectiveness

While pure nickel components can be expensive, nickel clad plates provide the desired corrosion resistance at a lower cost. By bonding a thin layer of nickel to a steel substrate, manufacturers achieve performance similar to solid nickel at a fraction of the price.

2. Enhanced Mechanical Properties

The steel core of nickel clad plates provides excellent mechanical strength, including high tensile strength and impact resistance. This combination ensures that the plates can withstand mechanical stresses in demanding applications.

3. Versatility

Nickel clad plates can be tailored to specific requirements by adjusting the thickness of the nickel layer and the type of steel used. This flexibility allows for customization based on the intended application.

4. Longevity

The corrosion resistance of nickel clad plates extends the service life of equipment, reducing downtime and maintenance costs. This longevity translates to increased operational efficiency and cost savings over time.

5. Compliance with Standards

Nickel clad plates are manufactured in accordance with international standards such as ASTM A265, ensuring quality and reliability. Compliance with these standards is crucial for applications in regulated industries.

Nickel clad plates are a versatile and cost-effective solution for industries requiring materials that combine strength and corrosion resistance. Their applications span across chemical processing, power generation, marine engineering, and more. By understanding their benefits and proper usage, industries can enhance equipment longevity, safety, and performance.

Contact Us

For more information on nickel clad plates and how they can benefit your specific applications, please reach out to us:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with your material needs and provide tailored solutions for your industry.