Q235B+316L Stainless Steel Composite Plate: High-Performance Material for Your Needs

Welcome to Baoji City ShenAo Metal Materials Co., Ltd., your trusted supplier for premium composite materials like the Q235B+316L stainless steel composite plate. This exceptional material offers unparalleled corrosion resistance, high strength, and versatility, making it ideal for a range of demanding applications. Whether you're in the chemical, power, environmental protection, or marine industries, this product is designed to meet your specific needs with reliable performance and durability.

Product Introduction

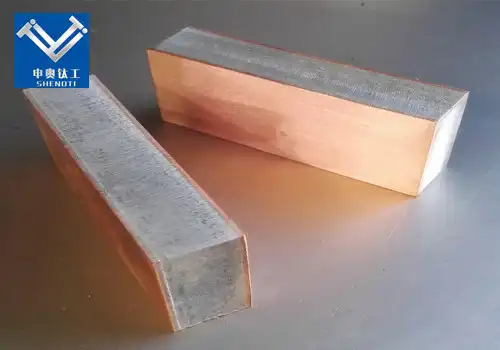

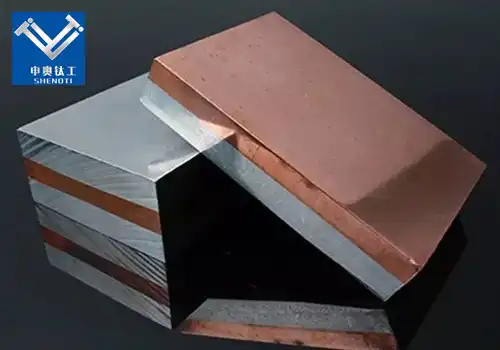

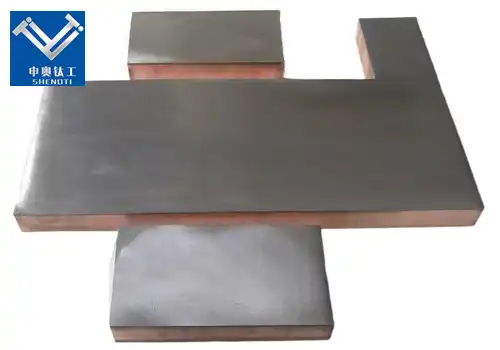

A Q235B+316L stainless steel composite plate is a bimetallic material manufactured through advanced cladding processes, where a layer of 316L stainless steel is metallurgically bonded to a Q235B carbon steel base.

Q235B carbon steel: Known for its excellent strength, toughness, and weldability, it serves as the structural base.

316L stainless steel: Featuring high corrosion resistance, particularly in chloride environments, it acts as the protective surface layer.

This dual-layer structure ensures that the material maintains mechanical strength while also resisting chemical attack, making it suitable for demanding environments such as seawater exposure, acidic conditions, and high-pressure systems.

Technical Specifications

| Property | Q235B+316L Stainless Steel Composite Plate |

|---|---|

| Base Metal | Q235B Carbon Steel |

| Cladding Material | 316L Stainless Steel |

| Thickness | Customizable (from 3mm to 50mm) |

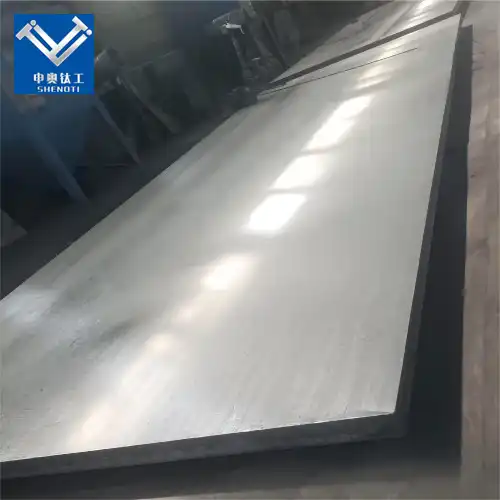

| Width | Up to 2500mm |

| Length | Up to 6000mm |

| Density | 7.85 g/cm³ |

| Tensile Strength | 500-600 MPa (Q235B), 520-700 MPa (316L) |

| Yield Strength | 235 MPa (Q235B), 290 MPa (316L) |

| Corrosion Resistance | Excellent, particularly in chloride environments |

| Hardness | HRC 45-55 (Q235B), HRC 20-30 (316L) |

| Welding Method | Explosion Welding |

| Operating Temperature | Up to 800°C |

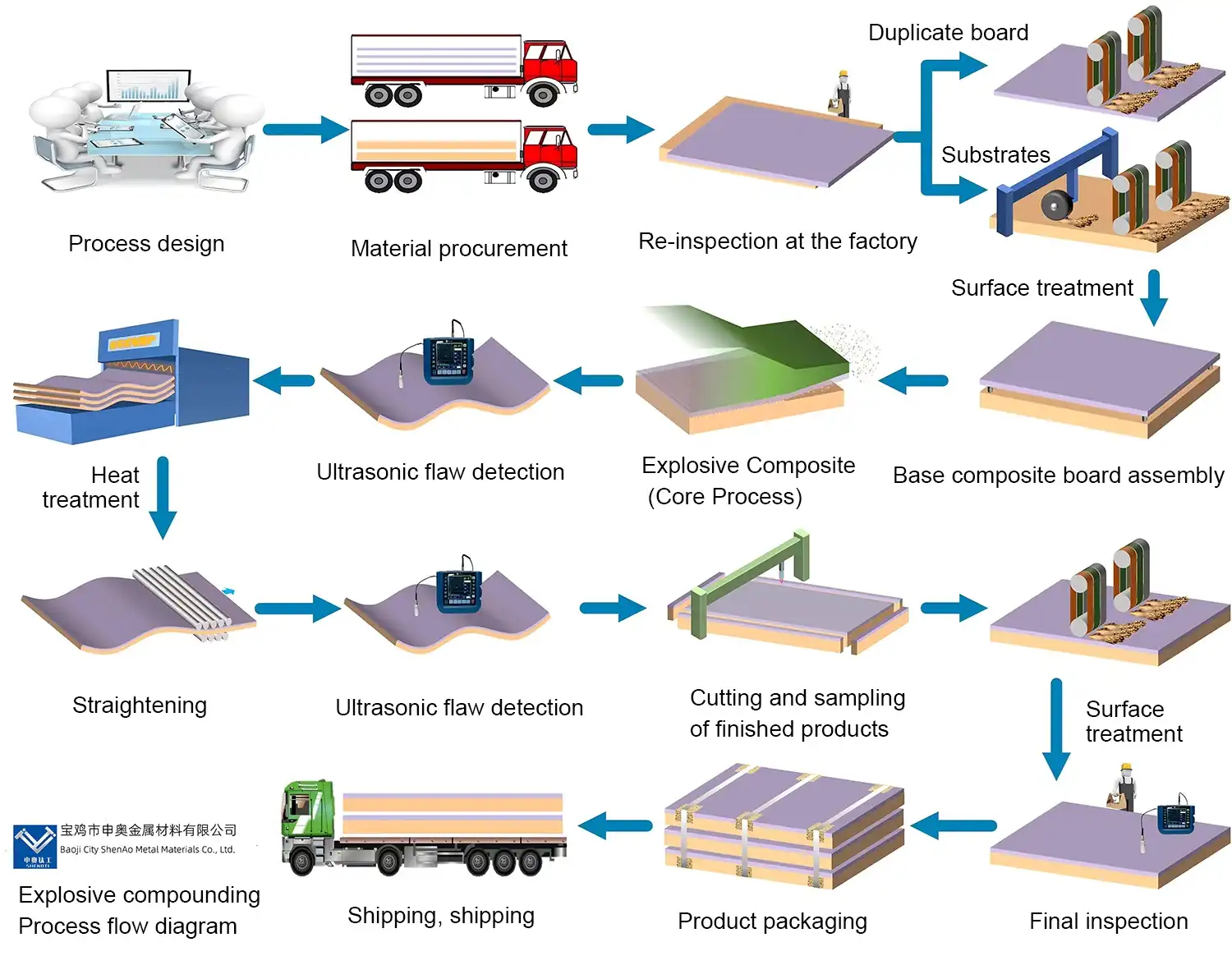

Manufacturing Process of Q235B+316L Stainless Steel Composite Plate

1. Explosion Bonding Technology

The most widely used process for producing Q235B+316L stainless steel composite plate is explosion welding (explosion bonding). In this method, a controlled detonation drives the stainless steel plate onto the carbon steel base, creating a solid metallurgical bond at the interface.

2. Key advantages of explosion welding:

Strong interfacial bonding without thermal deformation.

Large plate sizes can be produced.

Maintains the chemical composition and mechanical properties of both materials.

3. Hot Rolling Process

Another technique is hot rolling bonding, where the Q235B base plate and 316L stainless steel sheet are rolled together under high temperature and pressure. This process achieves metallurgical fusion and ensures a smooth surface finish.

4. Q235B+316L stainless steel composite plate quality control and testing, including:

Ultrasonic testing for bond integrity.

Tensile and shear strength testing.

Corrosion resistance tests in simulated service environments.

These processes guarantee high performance and long service life for industrial applications.

|

|

|

|

Advantages of Q235B+316L Stainless Steel Composite Plate

1. Cost-Effectiveness

By using Q235B carbon steel as the base, overall material costs are reduced while still providing the corrosion resistance of 316L stainless steel.

2. Superior Corrosion Resistance

The 316L stainless steel surface ensures protection against seawater, chemical solutions, and acidic gases.

3. High Mechanical Strength

Q235B carbon steel provides robustness and structural integrity, allowing the plate to withstand high pressure and heavy loads.

4. Weldability and Machinability

The composite plate is easy to fabricate, weld, and form into complex structures.

5. Extended Service Life

Combining the best properties of both metals significantly enhances durability in harsh conditions.

Application fields of Q235B+316L stainless steel composite plate

1. Petrochemical Industry

In refineries, pipelines, and chemical reactors, the Q235B+316L stainless steel composite plate provides both strength and corrosion resistance, reducing maintenance costs and extending service life.

2. Marine and Offshore Engineering

For ships, offshore platforms, and desalination plants, the plate withstands seawater corrosion and high mechanical stresses, ensuring safety and reliability.

3. Construction and Infrastructure

The composite plate is widely used in architectural cladding, bridges, and industrial structures where both aesthetics and durability are required.

4. Power Generation

In thermal and nuclear power plants, it is used for heat exchangers, condensers, and pressure vessels that demand excellent performance under high temperatures and corrosive environments.

5. Pressure Vessels and Storage Tanks

The Q235B+316L stainless steel composite plate is ideal for manufacturing pressure vessels, LNG storage tanks, and chemical containers, where both high strength and corrosion resistance are vital.

|

|

|

|

|

|

|

Product production process

Case Studies of Q235B+316L Stainless Steel Composite Plate

1: Chemical Reactor Lining

A petrochemical plant required corrosion-resistant reactors. By using Q235B+316L stainless steel composite plate, the reactor maintained high pressure resistance while preventing acid corrosion, extending its lifespan by 30%.

2: Offshore Oil Platform

An offshore platform in Southeast Asia adopted Q235B+316L stainless steel composite plate for structural components exposed to seawater. The result was reduced maintenance frequency and significant cost savings compared to pure stainless steel.

3: Power Plant Heat Exchanger

In a thermal power plant, the composite plate was used in heat exchanger tubing plates, ensuring excellent heat transfer and corrosion resistance under extreme operating conditions.

Why Choose Us?

At Baoji City ShenAo Metal Materials Co., Ltd., we are committed to delivering high-quality products and unparalleled customer service. Here are the key reasons why you should choose us as your trusted supplier:

1. Research and Innovation

Our experienced R&D team is dedicated to exploring new processes and applications. We continuously innovate to ensure our products meet the evolving needs of our customers.

2. Excellent Reputation

With 17 years of experience, we have built a strong reputation for delivering reliable, high-quality products. Our clients trust us for our consistency and expertise.

3. Striving for Excellence

We maintain strict production processes and a comprehensive quality management system, ensuring every product meets the highest standards.

4. Customized Product Services

We offer tailored solutions based on specific customer requirements. Whether it's the size, thickness, or application, we provide a product that fits your needs perfectly.

5. Timely Delivery, Worry-Free After-Sales Service

We are committed to delivering your orders promptly, with excellent after-sales support to ensure customer satisfaction.

6. OEM Services

We provide OEM services to meet the unique needs of our clients, ensuring that the final product matches their specifications.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is the maximum thickness available for the Q235B+316L composite plate?

A1: The maximum thickness we offer is 50mm, but we can customize it according to your specific requirements.

Q2: Can the Q235B+316L composite plate be used in high-temperature environments?

A2: Yes, the composite plate can withstand temperatures up to 800°C, making it suitable for high-temperature applications.

Q3: How does the welding process work for this composite plate?

A3: The composite plate is made using explosion welding, a process that creates a strong bond between the Q235B and 316L layers, ensuring durability and reliability.

Q4: Is there any corrosion protection for the Q235B base material?

A4: The 316L stainless steel cladding provides exceptional corrosion resistance, protecting the Q235B base material from corrosion and extending the life of the plate.

Contact Us

If you are looking for high-performance materials for your industrial applications, Baoji City ShenAo Metal Materials Co., Ltd. is here to help. Get in touch with us for customized solutions and professional support.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

We are ready to assist you with your material needs, ensuring a solution that fits your project specifications perfectly.

YOU MAY LIKE