What Are the Advantages of Zirconium Clad Plates in Pressure Vessels?

2025-05-12 15:53:04

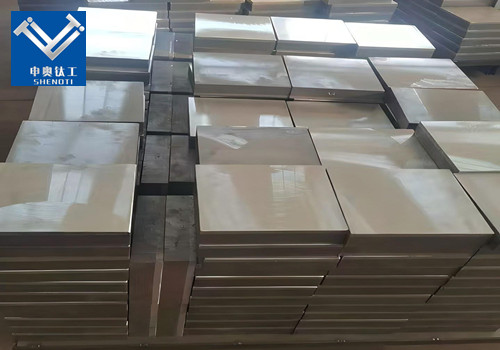

Zirconium Clad Plates for Pressure Vessels

Zirconium clad plates have emerged as a pivotal material in the construction of pressure vessels, especially in industries where corrosion resistance and structural integrity are paramount. By combining the exceptional corrosion resistance of zirconium with the mechanical strength of base metals like carbon steel or stainless steel, these clad plates offer a cost-effective solution for demanding applications.

What Are the Advantages of Zirconium Clad Plates in Pressure Vessels?

Zirconium clad plates offer a unique combination of properties that make them highly advantageous for use in pressure vessels:

1. Exceptional Corrosion Resistance

Zirconium exhibits outstanding resistance to a wide range of corrosive environments, including strong acids like hydrochloric and sulfuric acids. This makes zirconium clad plates ideal for chemical processing equipment, where corrosion can lead to equipment failure and safety hazards .

2. Cost-Effectiveness

While pure zirconium is expensive, cladding a thin layer of zirconium onto a more affordable base metal like carbon steel significantly reduces costs without compromising on corrosion resistance. This approach provides a cost-effective solution for industries requiring the benefits of zirconium .

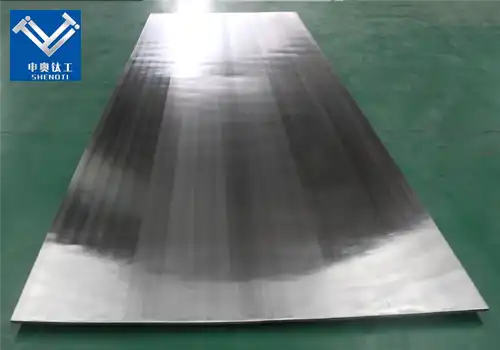

3. Mechanical Strength and Structural Integrity

The base metal in zirconium clad plates provides the necessary mechanical strength and structural integrity required for pressure vessels. This ensures that the vessels can withstand high pressures and mechanical stresses while the zirconium layer protects against corrosion.

4. Thermal Stability

Zirconium maintains its structural integrity at elevated temperatures, making it suitable for applications involving high-temperature processes. This thermal stability is crucial for pressure vessels operating under extreme conditions .

5. Longevity and Reduced Maintenance

The corrosion resistance and mechanical strength of zirconium clad plates contribute to the longevity of pressure vessels. This reduces the frequency of maintenance and replacements, leading to lower operational costs over time.

How Are Zirconium Clad Plates Manufactured?

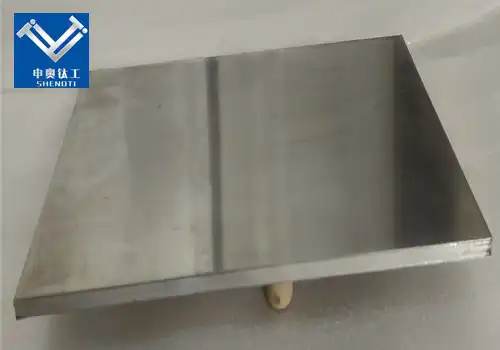

The manufacturing of zirconium clad plates involves bonding a layer of zirconium onto a base metal. Several methods are employed to achieve this metallurgical bond:

1. Explosion Cladding

Explosion cladding is a process where controlled explosive energy is used to bond zirconium to the base metal. This method creates a strong metallurgical bond without melting the metals, preserving their individual properties. Explosion cladding is widely used due to its ability to bond dissimilar metals effectively .

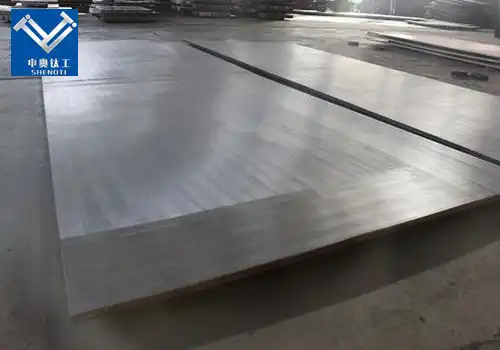

2. Hot Rolling

In hot rolling, zirconium and the base metal are heated and passed through rollers to bond them together. This method is suitable for producing large quantities of clad plates with uniform thickness.

3. Welding Techniques

Advanced welding techniques, such as electron beam welding, are used to join zirconium to the base metal. These methods are precise and suitable for complex shapes and configurations.

4. Interlayer Use

Sometimes, an interlayer metal like titanium is used between zirconium and the base metal to facilitate bonding and reduce residual stresses. This approach enhances the overall performance of the clad plate .

What Industries Use Zirconium Clad Plates?

Zirconium clad plates are utilized across various industries due to their unique properties:

1. Chemical Processing Industry

In chemical processing plants, equipment is often exposed to highly corrosive substances. Zirconium clad plates are used to construct reactors, heat exchangers, and piping systems that can withstand these harsh environments, ensuring safety and longevity .

2. Nuclear Power Industry

Zirconium's low neutron absorption cross-section and corrosion resistance make it ideal for nuclear applications. Zirconium clad plates are used in reactor vessels and other components where radiation resistance is critical .

3. Pharmaceutical Industry

The pharmaceutical industry requires equipment that maintains product purity. Zirconium clad plates are used in reactors and storage vessels to prevent contamination from corrosion, ensuring the integrity of pharmaceutical products .

4. Desalination Plants

Desalination processes involve exposure to saline environments that can cause corrosion. Zirconium clad plates are employed in heat exchangers and piping systems to resist corrosion from seawater, enhancing the durability of desalination equipment .

5. Aerospace Industry

Zirconium's high strength-to-weight ratio and thermal stability make it suitable for aerospace applications. Clad plates are used in components that require both strength and resistance to high temperatures .

Zirconium clad plates offer a combination of corrosion resistance, mechanical strength, and cost-effectiveness, making them an excellent choice for pressure vessels across various industries. Their unique properties address the challenges posed by corrosive environments and high-pressure applications, ensuring safety, longevity, and operational efficiency.

Contact Us

For more information about zirconium clad plates and how they can benefit your applications, please contact us:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with your specific requirements and provide tailored solutions to meet your needs.

YOU MAY LIKE

_1735019249058.webp)