High strength and durability for demanding applications.

Excellent thermal and electrical conductivity performance.

Customizable sizes to suit specific project needs.

Reliable bonding ensures long-lasting structural integrity.

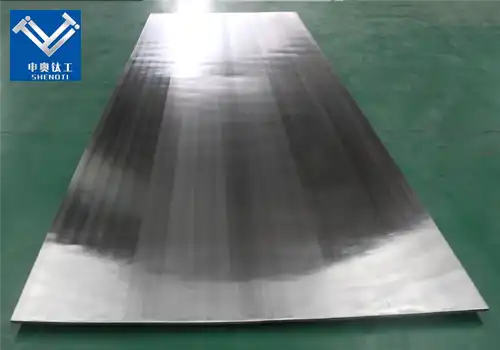

What is a Copper Aluminum Copper Clad Plate?

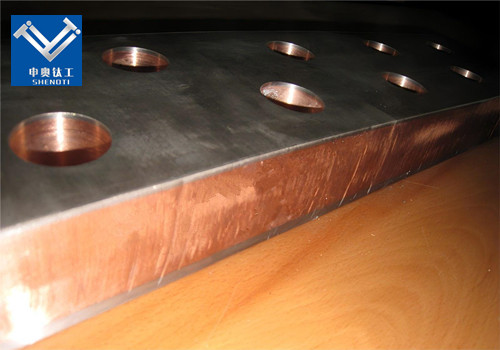

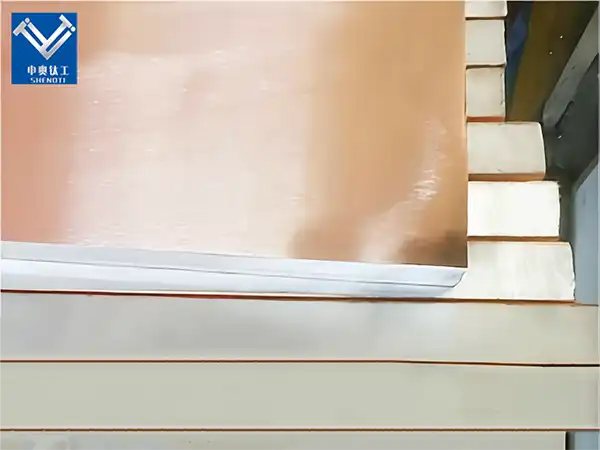

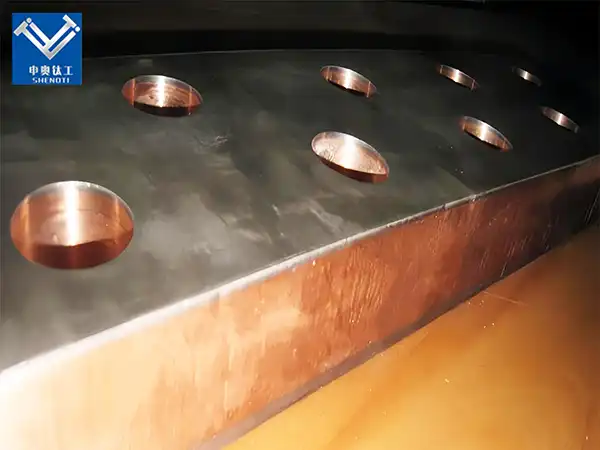

A copper aluminum copper clad plate is a composite material created by bonding layers of copper and aluminum together through a high-tech process known as explosion welding or roll bonding. This material is designed to combine the benefits of both copper and aluminum—copper offers excellent electrical conductivity and durability, while aluminum provides lightness and superior resistance to corrosion.

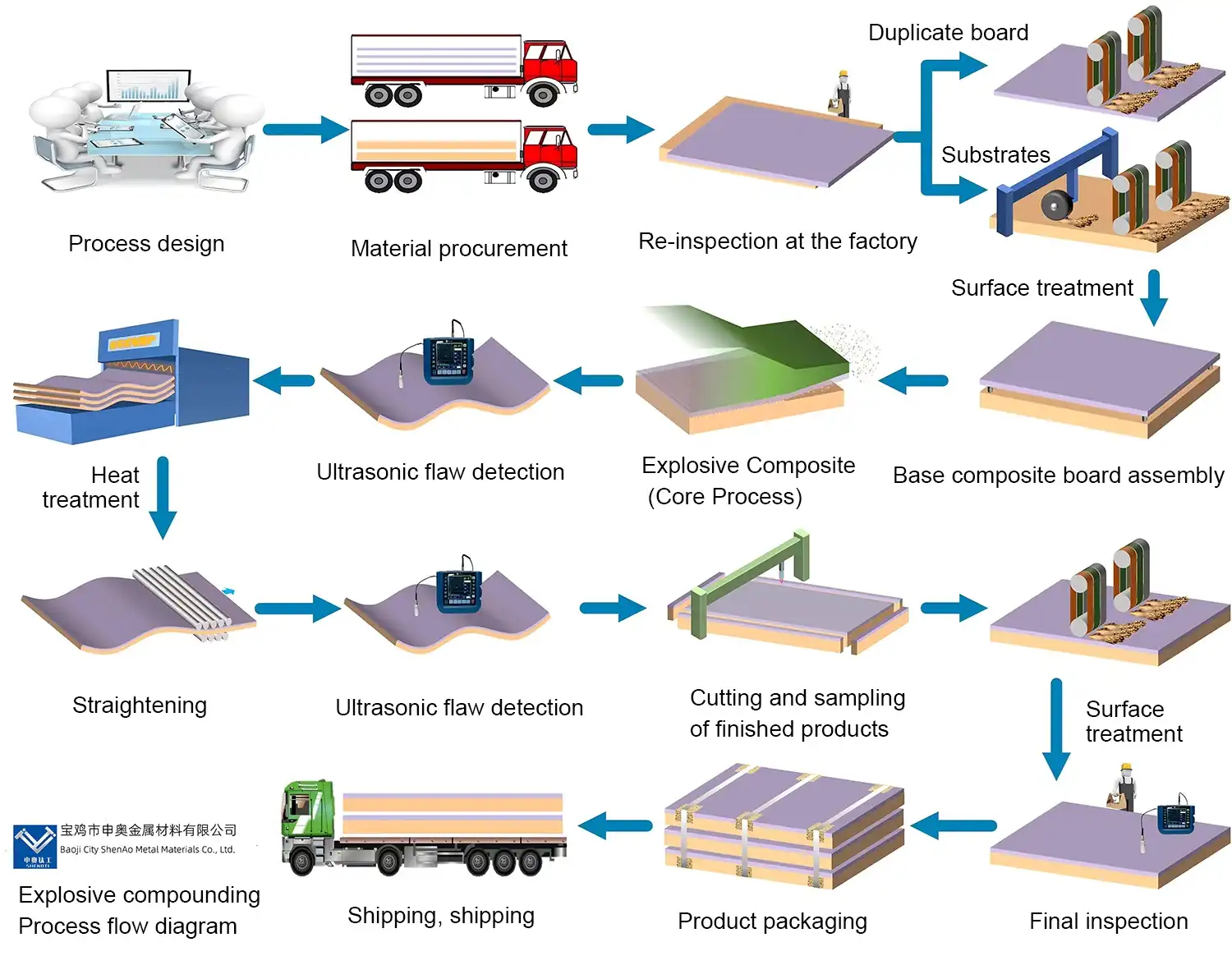

Manufacturing Process of Copper Aluminum Copper Clad Plate

The production of copper aluminum copper clad plates involves advanced techniques to ensure a strong bond between the copper and aluminum layers. The two most common manufacturing methods are:

Explosion Welding

Explosion welding is a high-energy bonding process where a thin layer of copper is explosively bonded to a layer of aluminum. This method ensures a robust and durable bond, creating a material that is both strong and flexible.

Roll Bonding

Roll bonding is a cold-rolling process in which the copper and aluminum are pressed together under high pressure, causing the two metals to adhere seamlessly. This process is highly effective for creating thin, uniform layers of copper and aluminum.

Both methods result in a composite material that combines the advantages of copper and aluminum in a single, efficient product.

Technical Specifications

| Specification | Value |

|---|---|

| Material Composition | Copper-Aluminum-Copper |

| Copper Layer Thickness | 1mm–10mm |

| Aluminum Core Thickness | 1mm–50mm |

| Bonding Strength | ≥140 MPa |

| Electrical Conductivity | Copper layer: ≥97% IACS |

| Thermal Conductivity | ≥180 W/(m·K) |

| Density | 4.3 g/cm³ (approx.) |

| Corrosion Resistance | Excellent in marine and industrial environments |

| Processing Capability | Cutting, punching, bending, and welding |

Our custom manufacturing capabilities allow for further customization of thickness, dimensions, and technical properties to suit your project needs about copper aluminum copper clad plate.

|

|

|

Advantages of Copper Aluminum Copper Clad Plate

1: Superior Electrical Conductivity

Copper offers excellent electrical conductivity. When clad onto both sides of an aluminum core, it maintains low-resistance pathways for current flow, making copper aluminum copper clad plates ideal for busbars, connectors, and electrode components.

2: Excellent Thermal Performance

The high thermal conductivity of copper, combined with aluminum’s heat dissipation capacity, creates a clad plate with exceptional thermal performance, perfect for LED heat sinks, power modules, and industrial cooling components.

3: Lightweight & Cost-Effective

Compared with pure copper plates, CACP reduces weight by nearly 50% and significantly lowers material costs, while maintaining similar performance in many applications.

4: Strong Metallurgical Bonding

Modern manufacturing techniques like explosion welding and hot rolling produce strong interfacial bonding, ensuring mechanical integrity and long-term durability, even in high-temperature or corrosive environments.

Key Applications of Copper Aluminum Copper Clad Plate

1: Power Industry (Busbars, Electrical Contacts)

In electrical substations, renewable power stations, and power distribution systems, CACP busbars are replacing solid copper busbars due to their lightweight structure and comparable electrical performance.

2: Battery Tabs and Lithium Battery Connectors

With the rise of electric vehicles and energy storage systems, copper aluminum copper clad plates are widely used in battery tabs, especially for connecting aluminum core battery cells with copper terminals. This eliminates the need for welding dissimilar metals.

3: Electronics and PCB Heat Dissipation Systems

CACP offers superior heat transfer capabilities, making it ideal for printed circuit boards, chip cooling substrates, and LED light heat sinks. The copper-aluminum interface ensures efficient temperature management in compact designs.

4: Automotive and Rail Transit

Automobile manufacturers are adopting copper aluminum copper clad plates in high-power connectors, EV battery systems, and rail transit power systems due to their strength, conductivity, and reduced weight.

Case Successful Applications of Copper Aluminum Copper Clad Plates

1: Electrical Power Distribution Systems

A major utility company used copper aluminum copper clad plates to replace traditional copper busbars in their electrical power distribution systems. The lighter weight of the material reduced installation costs, while the copper's high conductivity ensured reliable power transmission.

2: Automotive Battery Systems

An automotive manufacturer implemented copper aluminum copper clad plates in their electric vehicle battery systems. The combination of light weight and durability helped increase the energy efficiency of their vehicles, while reducing the overall weight, which is critical in electric vehicle performance.

3: Offshore Oil Rig Components

A marine engineering company used copper aluminum copper clad plates for the construction of components for an offshore oil rig. The plates' resistance to corrosion and ability to withstand extreme temperatures ensured the long-term reliability of the equipment in the harsh marine environment.

|

|

|

|

|

|

|

Product production process

Why Choose Baoji City ShenAo Metal Materials Co., Ltd.?

1. Research and Innovation

Our experienced R&D team continuously develops new processes and applications, ensuring cutting-edge products that meet industry demands.

2. Proven Reputation

With 17 years of experience, we have established a trusted brand known for quality and reliability.

3. Excellence in Production

Our strict quality management system guarantees consistent product performance, whether for small-batch testing or large-scale production.

4. Customization Services

We provide customized solutions that cater to specific specifications and technical demands, guaranteeing the success and efficiency of your project. Our commitment to meeting your unique needs is paramount, and we work closely with you to ensure that every detail is aligned with your vision and goals.

5. Timely Delivery and Support

Our logistics are streamlined for punctual delivery, and our customer-focused approach provides hassle-free post-sale assistance, ensuring that our clients receive their orders on time and with the support they need to address any concerns that may arise after purchase.

6. OEM Services

Our efficient manufacturing and logistics systems are designed to guarantee the punctual delivery of your orders, ensuring reliability and consistency in our service to you for copper aluminum copper clad plate.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

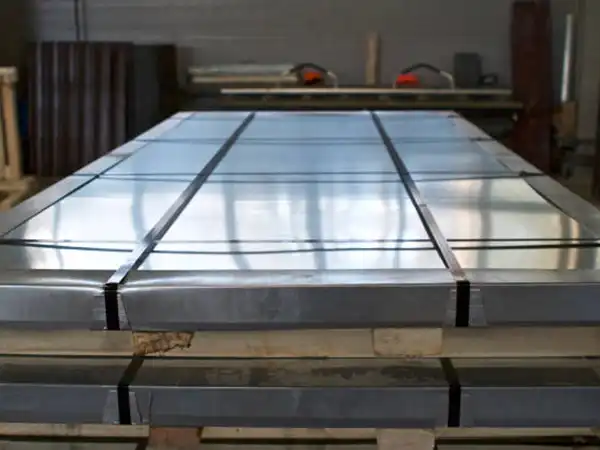

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

1. What is the typical lead time for the Copper aluminum copper clad plate?

Lead times vary depending on order size and customization requirements. Typically, orders are completed within 2–4 weeks.

2. Can the thickness of the copper and aluminum layers be customized?

Yes, we offer full customization of layer thicknesses to match your specific project needs.

3. What industries benefit most from this product?

Key industries include electrical power equipment, environmental engineering, electronics, and marine applications.

4. How do you ensure product quality?

We adhere to strict quality control standards and utilize advanced explosive welding technology to guarantee product integrity.

Contact Us

Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Let us provide the high-performance solutions you need for your next project about copper aluminum copper clad plate!

YOU MAY LIKE

(1)_1734580705587.webp)