In What Fields Are Zirconium Alloy Steel Composite Plates Used?

2025-05-12 16:28:00

In What Fields Are Zirconium Alloy Steel Composite Plates Used?

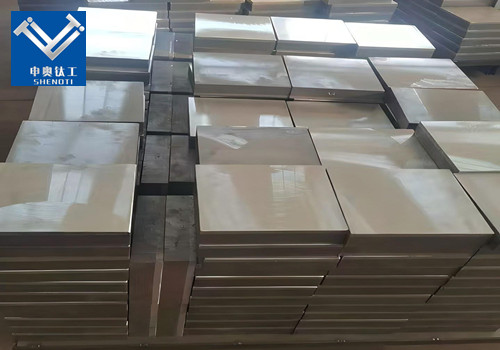

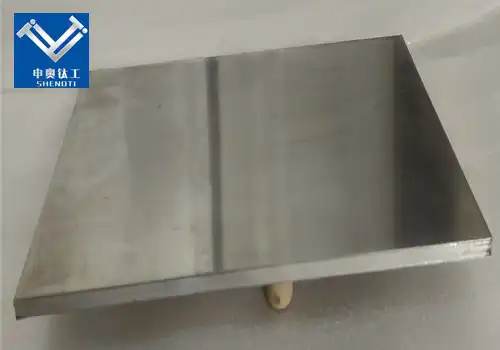

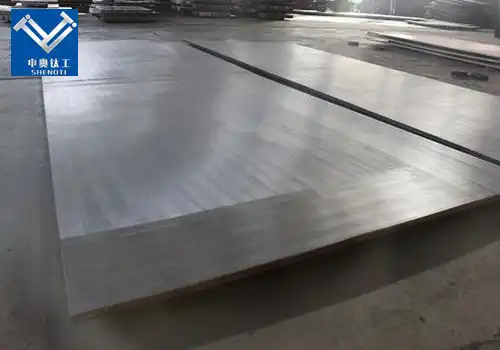

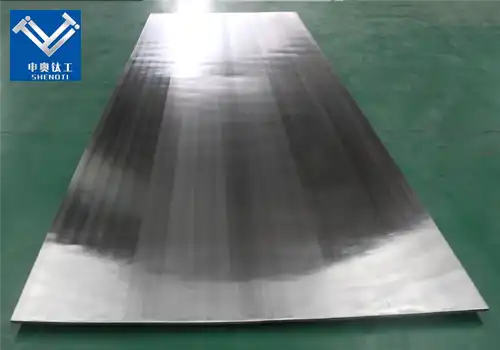

Zirconium alloy steel composite plates, commonly known as zirconium clad plates, are advanced materials that combine the exceptional corrosion resistance of zirconium with the structural strength and cost-effectiveness of steel.

What Are the Primary Applications of Zirconium Clad Plates?

1. Chemical Processing Industry

The chemical processing industry is one of the foremost sectors utilizing zirconium clad plates. These plates are extensively employed in the construction of equipment such as reactors, heat exchangers, and piping systems that handle highly corrosive substances like hydrochloric acid, sulfuric acid, and nitric acid. The zirconium layer provides exceptional resistance to corrosion, ensuring the longevity and safety of the equipment, while the steel base offers the necessary mechanical strength.

2. Nuclear Power Industry

In nuclear power plants, zirconium clad plates are utilized due to zirconium's low neutron absorption cross-section and excellent corrosion resistance in high-temperature water environments. These properties make zirconium ideal for components such as fuel rod cladding, reactor vessels, and heat exchangers. The steel backing provides structural integrity, ensuring the safe and efficient operation of nuclear reactors.

3. Pharmaceutical Industry

The pharmaceutical industry requires materials that can withstand exposure to highly pure and often corrosive chemicals without contaminating the products. Zirconium clad plates are used in reactors, mixing tanks, and storage vessels to ensure product purity and equipment longevity. The corrosion-resistant zirconium layer prevents contamination, while the steel base provides the necessary mechanical strength for high-pressure applications.

4. Desalination Plants

Desalination plants, which convert seawater into fresh water, utilize zirconium clad plates due to their superior corrosion resistance to chlorides and other salts present in seawater. These plates are used in components like heat exchangers and piping systems, where the zirconium layer protects against corrosion, and the steel base offers structural integrity, ensuring long-term durability in aggressive saline environments.

5. Marine Industry

The marine industry benefits from zirconium clad plates in the construction of shipbuilding components and offshore structures that are exposed to harsh marine environments. The corrosion-resistant properties of zirconium protect against seawater-induced degradation, while the steel base provides the necessary strength to withstand mechanical stresses.

Why Are Zirconium Clad Plates Preferred Over Other Materials?

Exceptional Corrosion Resistance

Zirconium exhibits outstanding resistance to a wide range of corrosive agents, including strong acids and alkalis. This property is primarily due to the formation of a stable, protective oxide layer on its surface, which prevents further corrosion. This makes zirconium clad plates highly suitable for environments where other materials would rapidly degrade.

High-Temperature Stability

Zirconium maintains its mechanical properties and structural integrity at elevated temperatures, making zirconium clad plates ideal for applications involving high-temperature processes. This thermal stability ensures reliable performance in demanding industrial settings.

Mechanical Strength and Cost-Effectiveness

By combining a zirconium layer with a steel base, zirconium clad plates offer the corrosion resistance of zirconium and the mechanical strength of steel at a lower cost compared to using solid zirconium. This makes them an economically viable solution for industries requiring both durability and corrosion resistance.

Versatility and Fabrication Ease

Zirconium clad plates can be fabricated using various methods, including explosion cladding, which ensures a strong metallurgical bond between the zirconium and steel layers. This versatility allows for the production of complex shapes and sizes, catering to specific industrial requirements.

How Are Zirconium Clad Plates Utilized in the Chemical Processing Industry?

In the chemical processing industry, equipment is often exposed to highly corrosive substances, necessitating materials that can withstand such harsh environments. Zirconium clad plates are extensively used in this sector due to their exceptional corrosion resistance and mechanical strength.

Equipment Applications

Reactors: Zirconium clad plates are used in the construction of reactors that handle corrosive chemicals, ensuring long-term durability and safety.

Heat Exchangers: The plates are employed in heat exchangers where they resist corrosion from aggressive chemical media, maintaining efficient heat transfer over time.

Piping Systems: Zirconium clad plates are used to fabricate pipes that transport corrosive substances, preventing leaks and prolonging the lifespan of the piping systems.

Economic and Operational Benefits

The use of zirconium clad plates in chemical processing equipment leads to reduced maintenance costs, minimized downtime, and enhanced safety. Their durability ensures prolonged service life, making them a cost-effective choice for the industry.

Contact Us

At Baoji City Shenao Metal Materials Co., Ltd, we specialize in the production of high-quality zirconium clad plates tailored to meet the specific needs of various industries. Our advanced manufacturing processes and commitment to excellence ensure that our products deliver superior performance and reliability.

For inquiries and more information, please contact us at:

Email: zh@baojiti.com.cn

We look forward to collaborating with you to provide solutions that meet your industrial requirements.

YOU MAY LIKE

_1735019249058.webp)